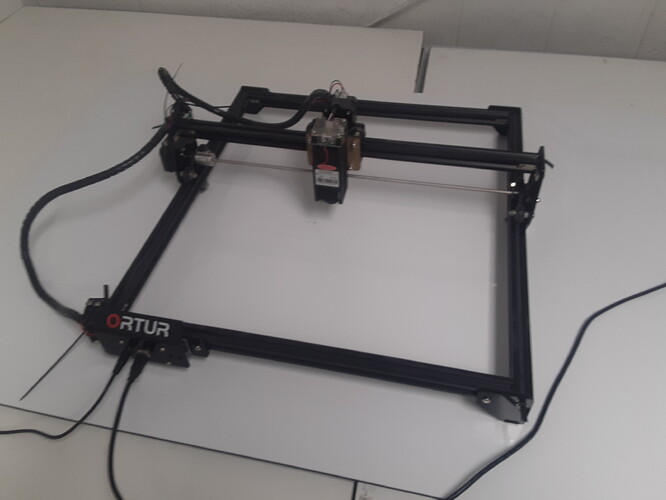

Hi everyone! So I am having some confusing issue with my Ortur Laser 2 (15 W)

We use it to etch our logo and names on the back of our panels, and I got everything working just fine, but had a weird issue yesterday.

If you look at the picture I attached, I was trying to etch on this ACM panel that is bigger than the machine, its (the panel) 6mm thick. I’ve etched 3 other panels that were “oversized” with no problems, and yesterday I did a test run on a smaller piece of ACM to make sure settings were correct, and it etched just fine, then moved over to the bigger piece and it will not etch/burn into it. Settings are the same, material is the same, and my friend suggested its because the smaller piece is technically closer to the laser while the larger pieces are just slight further away because its setting on top of the panel.

Any ideas or suggestions are appreciated.

6mm can make a difference, yes. ![]() Ortur recommends 35 to 40mm distance for good focus.

Ortur recommends 35 to 40mm distance for good focus.

Thank you so much for the reply. We are going to upgrade to a 20W soon. I just don’t know why I was able to etch 3 oversize panels, and not etch this panel. So it needs to be about 1.5 inches from the laser? Also, would there be a way to etch the oversize panels if I can’t get it that close?

You want to get the tightest spot you can (well the shape will not be a dot, more like a tiny dash). I do not know why you had success before and are now having issue trying to do the same, on the same.

I might continue testing, using the cutoffs under foot, to raise the frame to the same height as the full sheets, then test your pieces again. Ortur has had reports of a bad batch of motherboards that can fail, so this is worth keeping in mind as you continue your testing. You may have a bigger issue. ![]()

Cheers!

So I had some 6mm acm cutouts that i used to “raise” the ortur machine, and it wouldnt etch at all. As soon as I removed them it started etching immediately. Don’t worry I paused it in between times

My boss is going to take the piece off (acrylic-wood looking thing laser is attached to) and drill more holes in it so we can lower the laser, bringing it closer to the object of engraving/etching

Hey just wanted to close this up by saying the way I fixed this was by refocusing the laser! I found a great tutorial on how to do this here: Focusing a Diode Laser Quickly - Featuring the Ortur Laser Master 2 - YouTube

We are still going to upgrade the laser, but refocusing it and doing some test runs really helped!

Thanks for everyone that helped!

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.