We have a Chinese laser that came with a 150 to 180 Watts Reci tube which broke last week after 5 years. It looks like there was a short circuit because the high voltage connector was burnt, so we replaced the high voltage connector.

We had to buy a new tube. We went for a Yongli tube, 130-150w.

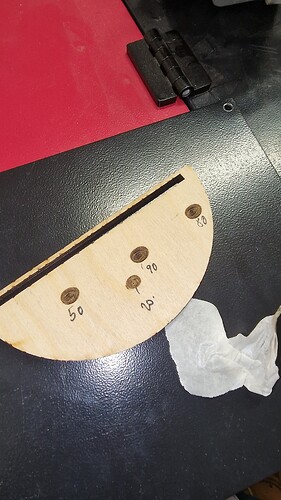

The issue now is that the laser beam seems to be divergent, when we shoot at the first mirror we get relatively small dot. I have attached an image with different power intensities shot straight from the larr end below.

At the second mirror it grows bigger and at the third one it is already very big. The washers inside the laser head were burned because of the big diameter of the laser beam.

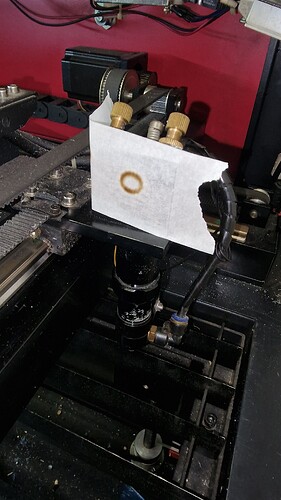

Additionally if the the laser beam is powered on a low power such as 13% it leaves a dot like a circle like a ring instead of a full circle. I attached an image.

Regarding amps I know we are supposed to work around 24 amps and the maximum powers should be 80%, however the issue is that at 80% we have around 36 amps instead of 24.

The tube is from 2021 production year .

The cut is almost all right.Apart from the fact that we can observe melting/ some bubbles on the top of the material.

The laser mirrors have just been calibrated and aligned.

I am interested in finding out if the divergence is a sign of a defective tube and what could be the cause for the bad cut and how to solve it.

Thanks ![]()