Do you get material presets with paid lic? Dose gcode work in free test verson or is the errors because i dont know what i am doing? I layed out a project engrave~cut operation and i get gcode error when i try to run it. I dont want to payfor it because it seems buggy with out these feature. Useing trial version.

There is no difference between the Trial and Paid version, except the Trial only lasts 30 days. Lightburn is one of the least-buggy software packages I have used. That said…

There is so much variety in materials that an included library of presets would be of limited value. Everyone builds their own reference by test burning each material they are using. New to the latest version is a tool to create a test burn grid.

Before you do anything, you need to make sure your machine is set up properly. Rather than give you a link, get a bunch of them by Googling “lightburn machine setup instructions” and follow the instructions offered. This is why the 30-day trial.

Finally, your machine may be properly set up, but you get errors anyhow. That is likely a layout issue, but you did not tell us what the error might be. That is where this forum shines. Give us some details so we can help. If we need more information, we will ask for it. Please be advised this is not just a users forum. The Lightburn developers constantly monitor and respond to postings where needed.

Welcome to Lightburn, this forum, and a boatload of things you can do with a laser.

And have some patience. This laser job/hobby/passion is not instant, there are just too many variables.

First question… What alarms/errors did you get and what were you trying to do?

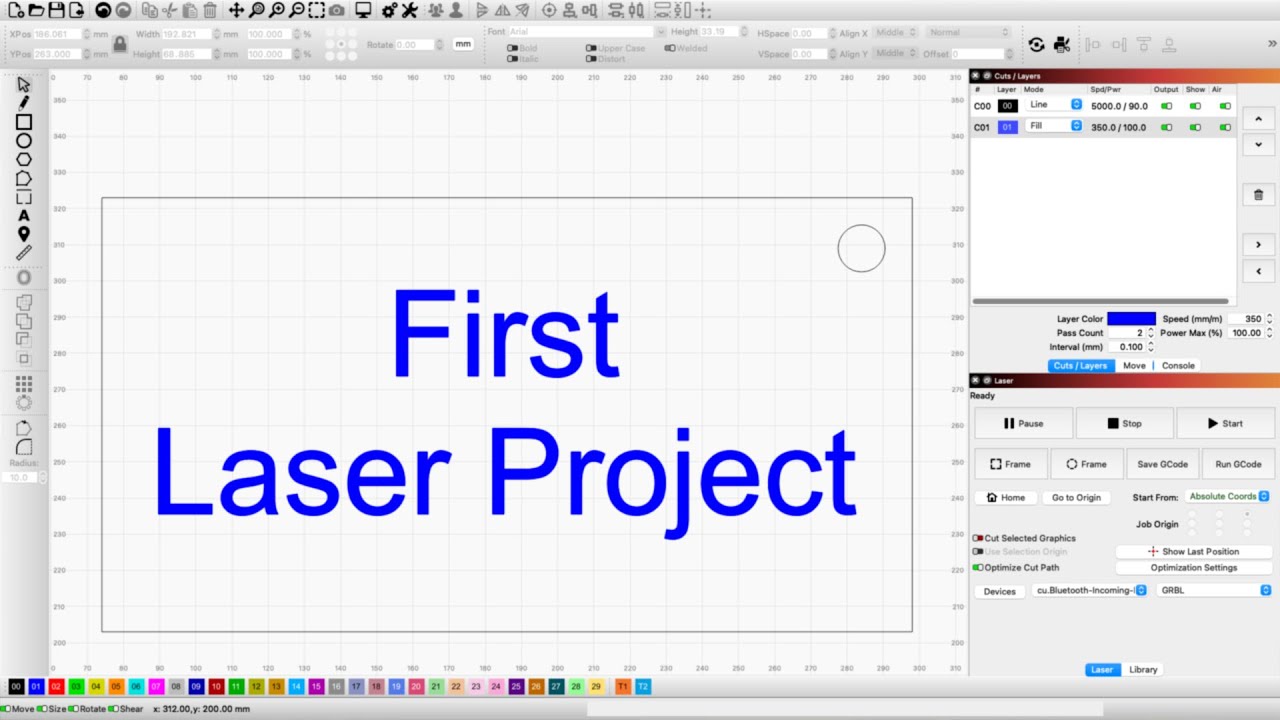

I like the software lay out. I used lasergrbl and if I am engraving wood it would give me a choice of wood settings bamboo, solid, or leather and other materials I am working with. I could get light burn to engrave on Lether. When I tried a more complex operation engrave cut it errored on me. It burned my project with a line then stopped.

tarting stream

Stream completed in 0:05

<Idle|MPos:88.800,90.400,0.000|Bf:15,127|FS:0,0|Ov:100,100,100>

ok

Starting stream

Layer C01

error:20

Unsupported or invalid g-code command found in block.

On or near line 0:

Job halted

Stream completed in 0:00

ok

ok

ok

ok

I don’t want to burn my project or my laser out guessing that settings are too high or not high enough. let me know if you need more code lines.

Starting stream

Stream completed in 0:00

Starting stream

Stream completed in 0:00

<Idle|MPos:112.162,95.050,-10.000|Bf:15,127|FS:0,0|WCO:0.000,0.000,0.000>

ok

Starting stream

Stream completed in 0:00

<Idle|MPos:102.162,95.050,-10.000|Bf:15,127|FS:0,0|WCO:0.000,0.000,0.000>

ok

Starting stream

Stream completed in 0:00

<Idle|MPos:92.162,95.050,-10.000|Bf:15,127|FS:0,0|WCO:0.000,0.000,0.000>

ok

Starting stream

Layer C01

error:20

Unsupported or invalid g-code command found in block.

On or near line 0:

Job halted

Stream completed in 0:00

ok

ok

ok

ok

ok

Grbl 1.1h [‘$’ for help]

Good morning. May I ask what is the output power of your laser?

Sculfun 5w engrave and cut thin luan. Thin wood.

I figured out how to get presets. Why would that not be already installed to give you a starting point? I can’t get it to engrave and then cut. The laser moves, then stop, and the compressor pumps.

has to be in gbrl… laser~edit

Here are some materials libraries for the 5W.

5W_MATLIB2_v2.21.clb (51.5 KB)

Ortur-Original-LM2-5.5W.clb (41.4 KB)

Sculpfun-S9-5W.clb (21.1 KB)

You need to put the engraving layer on top and the cutting layer below it, then in the optimization settings, choose “order by layer”

For the error:20 message you’re seeing:

Check to make sure your device is set up with the correct device profile, following these steps:

-Click “Devices” in the ‘Laser’ window

-Double click your laser in the list

-Make sure the selected device is ‘GRBL’

-click next until you’re done

You should also check to make sure you do not have GCode clustering enabled in your Device Settings (‘Edit’ > ‘Device Settings’).

Here’s a First Project video to help you get familiar with the basics of using LightBurn:

We have many more helpful videos on our YouTube channel, and written guides for beginners here:

I think you need to watch some instructional videos more than you need settings.

Also, LightBurn has a built in Material Test that should help.

It will make things much easier going forward. IMO

As Tyler mentioned, it’s your laser setup that’s wrong, not your settings. Follow this guide to setup up the Sculpfun with LightBurn: Setting up the software - Diode Laser Wiki

And regarding settings, here is a guide as well: Settings guide - Diode Laser Wiki

I appreciate everyone’s help. So far, in my laser journey. I have watched a lot of youtube and researched before dropping money on lasers and material. Most tutorials make it look easy. Then I tried to find the setting the video was talking about, and it was not as easy to find.

I have worked with other software that was not as easy as this program. The others made me frustrated that I couldn’t do anything extraordinary. When I started using Lightburn, I expected nothing but problems. When I hit the most common problem, I sometimes found the tabs challenging to find the setting I sought. I knew my equipment worked with the other software. Now that I know the tabs better and have done some projects. I like the versatility.

Sometimes the grouping of settings does not make sense to me. Why would the start program and box out the area be in a different location than the move laser features? Why does the box-out or band-out feature not continue to go around with the laser on 1% so I can line up my project and keep adjusting until I get it where I want it? When I click the feature and turn to the laser, it’s already half done going around. I did not even touch my item to make adjustments. It’s already stopped.

I am not concerned with presets being perfect. I hate watching the laser go back and forth, doing nothing because the power is too low, and I don’t want a smokey apartment. I do not want to watch the laser burn up or black out my engraving. I want a reasonable guess and do three-four passes or more to achieve what would take one or two passes in a workshop.

I am also struggling with homing the laser. I would run into a problem with the project and find it challenging to find the same spot in space to start, and when I tried to use the home features, the laser would go to the corner and not where I started the project the first time. Then I thought I marked where the start was and tried again. I did separate actions only image and stop check it, then started the cut operation stop. When I stopped it early and pressed home, it went to the corner, not where I told it. I did not move my material. I moved the laser around where I thought I had started for the cut actions. It was not the same place and made a double line of error because its start point was inconsistent.

I wanted to do more extensive, significant projects, but the small ones were too inconsistent to try a big project.

Each program I have used has one or a handful of easy-to-understand features easy to use. The rest of the features get confusing and frustrating, and I could not unlock the versatility of my hobby laser. Light Burn has some good features once you figure out how the program is laid out. No one software has the best layout, features, or consistency of operation for me so far.

In one action, I engraved four tomato pictures, miniature copies of the same image. When the operation was finished, I had four different colors, some nice and light with good detail. Some are darker and not as clear or detailed—all four different looking.

Lightburn is by far way better than other programs I have used. I hope light burn continues to improve this software.

I don’t know why my last post is in a horizontal text box. That makes it hard to read. I did not write it that way. I used the website text box to reply. It was fine with paragraphs. I posted it, and that’s what happened. Inconsistent.

It’s a Markdown syntax thing: a line starting with four or more spaces tells the post formatter to treat what follows as a single line of program text in a monospaced font.

Not what you might expect from a few blanks, but there it is.

@Shurtboy - Fixed it.

Four Leading spaces is a trigger to insert a Code Text box.

There are a myriad of features available.

![]()

Thank you for fixing my text.

I highly recommend reading the online documentation or PDF version (might be more comfortable) once. It’s a 250+ page document, but it’s really worth reading. Even if you don’t need any feature, it’s good to remember having read about it some time ago. I did, and it helped a lot in the beginning.

That’s because you usually do it the other way around. Place your object once in the workspace. Then move the laser to the desired position. Frame. Check if it fits. If not, move the laser to a new position, then frame again. It helps if you have the control PC close to the laser or a camera in the enclosure to see where the laser is.

But still, external presets don’t help much. But - I can tell you - the more experience you have, the better is your feeling for settings. In the end, there are only like three to four different settings you use, with slight adjustments to the material. You will have one major cutting setting, that you just will adjust to material thickness and type. Then you have a few engraving presets, that you adjust according to material and depths. Better to get those presets your own trough testing. Only then you really understand your preset.

Some people cut plywood at 200/100/1 (200mm/min, 100%, 1 pass). I cut it at 600/85/4. I think my setting is much better then the first, it creates much less charring. But you won’t get this information in a preset.

Again, check here for in-depth explanation: Settings guide - Diode Laser Wiki

You might take a look at different techniques here: Coordinate systems & workpiece alignment - Diode Laser Wiki In general - most diode laser mechanics don’t have absolutely exact mechanics. It’s very unlikely (independent of LightBurn functions) that you will ever exactly hit the same spot perfectly again. You would need to do some other adjustments (like constantly powering the motors; otherwise they lose steps) to achieve best results.

Stopping and restarting projects is higher laser art. Don’t try this in the beginning. Better to start off new if something fails.

That’s the way it goes. It takes much time to get into it, but I’m sure you will make it.

Sure. It’s hard to get something intuitive for every user. I only can tell that I found LightBurn the most intuitive laser control program I found and after using it for like two years, every little detail is consistent to me and I think I know (though not use) nearly every feature of it. Or, let’s say, 80% ![]() I also still struggle with some projects and learn new things every day

I also still struggle with some projects and learn new things every day ![]()

I recommend reading the wiki pages since they are originally written with for the S9, so much content should fit to your problems. It’s the essence of two years of (Sculpfun) user support that I did. Most common questions are answered there.

Do you drive a car, repair a lawn mower, sail a boat, play chess, or build a playhouse in the backyard? Many things we do start out complicated, but get easy as we continue to do it. Frustration is normal, especially if you can’t figure it out or it does not do what you think it should. How can you get a sense of accomplishment if there is no struggle?

It was a year before I got the laser to burn something. Then the next time it just moved around, no fire. Yes, I understand the frustration with these things but learning is a journey. Lightburn is a package that will continue to offer options as you try new materials and machines. I do not know their market share, but they are way ahead of whoever is in second place.

When you have a problem, make notes with details and come back to this Forum. I have yet to see a problem that was not eventually solved by the Lightburn Community. And I try to read every posting.