Hard agree!

However, weird things can happen, so keep the notion in mind after everything else gets ruled out.

Given that it works, I don’t see the beam splashing off the inside of the optics and changing its shape, particularly because that wouldn’t produce any dots. Combine it with a dotty power supply and maybe you’ve got something, but it’d take some convincing.

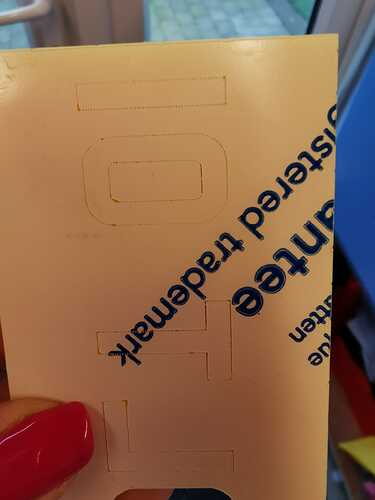

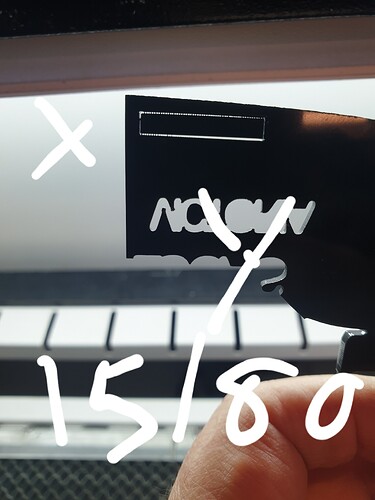

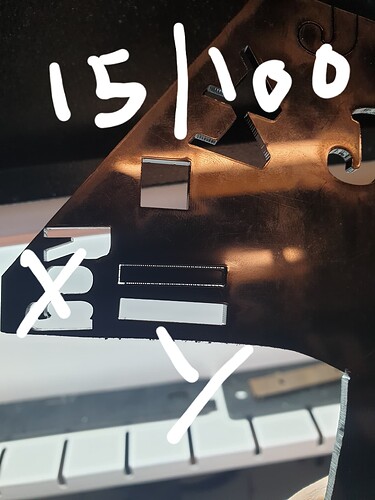

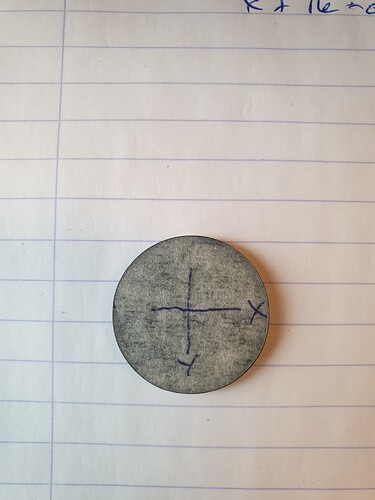

A quick beam alignment test to burn spots in targets at the X and Y mirrors, done at the four corners of the platform, would confirm that’s not the problem if all the spots are pretty much in the middle of the apertures.

If the spots aren’t nice and round, though: Bad Sign™.

That’s … odd.

Perhaps the Y axis has a motor pulley twice the diameter of the X axis, for reasons that surely made sense at the time. That would mean one step of the Y motor drives the laser head twice as far as one step on the X motor.

With all the mechanical bits being equal, perhaps the two stepper drivers have different pulse/rev settings, again for a reason lost in the mists of time. If the X driver has 8000 pulse/rev and the Y driver has 4000 pulse/rev, then the Y axis would move twice as far per step.

Neither of those would matter, because the controller knows how many steps it must send to move a specific distance. The two axes would have different speed and acceleration settings, but they would anyway because the Y axis must sling that big gantry around. If you were fussy about tuning, the motor speeds might make a difference, but these lasers aren’t running near their outer performance limits.

Just for completeness, stick your head inside and see if either of those guesses are right.

Not that I wish you any ill, but if it’s not the tube going bad, you’ve definitely got a puzzle on your hands.