Please test leading edge vs trailing edge and let us know.

Well hell, I didn’t know that was a link, I thought it was an ad! Reading it now, and it looks like it matches my symptoms. Gonna try it out tonight!

Thank you so much! Imma let you know.

I believe this is what @micrololin had advised…

![]()

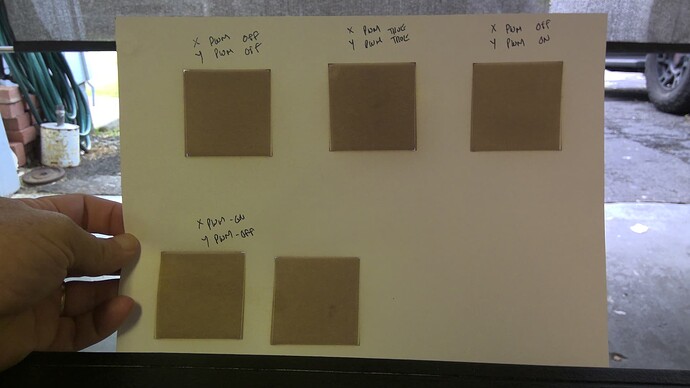

Ok, I tried the stock PWM settings to X and Y off, X and Y on, X on Y off, X off Y on. Item still skews, just to the left or right of the line cut box. The line box is set to 50 mm height and width, which is dead on per a caliper, and verified via diagonal measurements.

Im getting frustrated.

I believe the setting should be the same for both x and y. Both of mine are off.

I would try to do the same square test on all 4 corners of the bed and the center to see if there is any variation.

I would also cut this file out and check beam alignment at the nozzle in all 4 corners and center.

Beam Checker 2.lbrn2 (12.2 KB)

This file came from this forum but I couldn’t find it to link to.

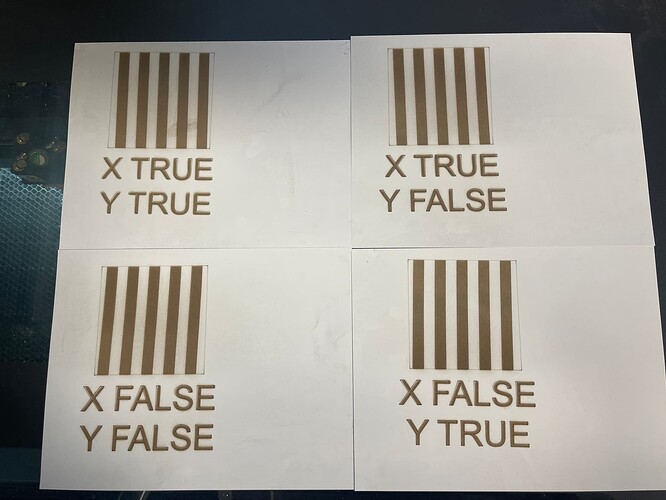

Update. I ran the laser with all 4 possible pwm setting combo’s, all it did was change the skew from right to left. I have cut the boxes in all 4 corners of the machine bed, with the same results in each location. Im stumped.

FIXED!!

Ok, after everything i tried, belt tension, pulley tension, hardware and software it turns out one of the side dip switches of the x controller was initially set at the factory incorrectly, and sent to me in the wrong configuration. Laguna tech support over a week or so of texting and emails helped me to find it. All is good in the world today.

FYI x and y controller should have matching dip switch settings on both front and side.

What X controller? Are you referring to the motor driver?

![]()

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.