My husband and I are attempting to etch an image in a small cross cut piece of wood. We noticed we are seeing double lettering on our work. What can we do to troubleshoot this as we have tried belt tightening, changing settings, etc. and it’s not resolving. Any ideas? We know the quality of the image isn’t the best but we can’t move forward with the double text. Thank you in advance.

As a start run the file in this post and post a picture.

We can’t move forward with that image either. A larger clearer one would help immensely.

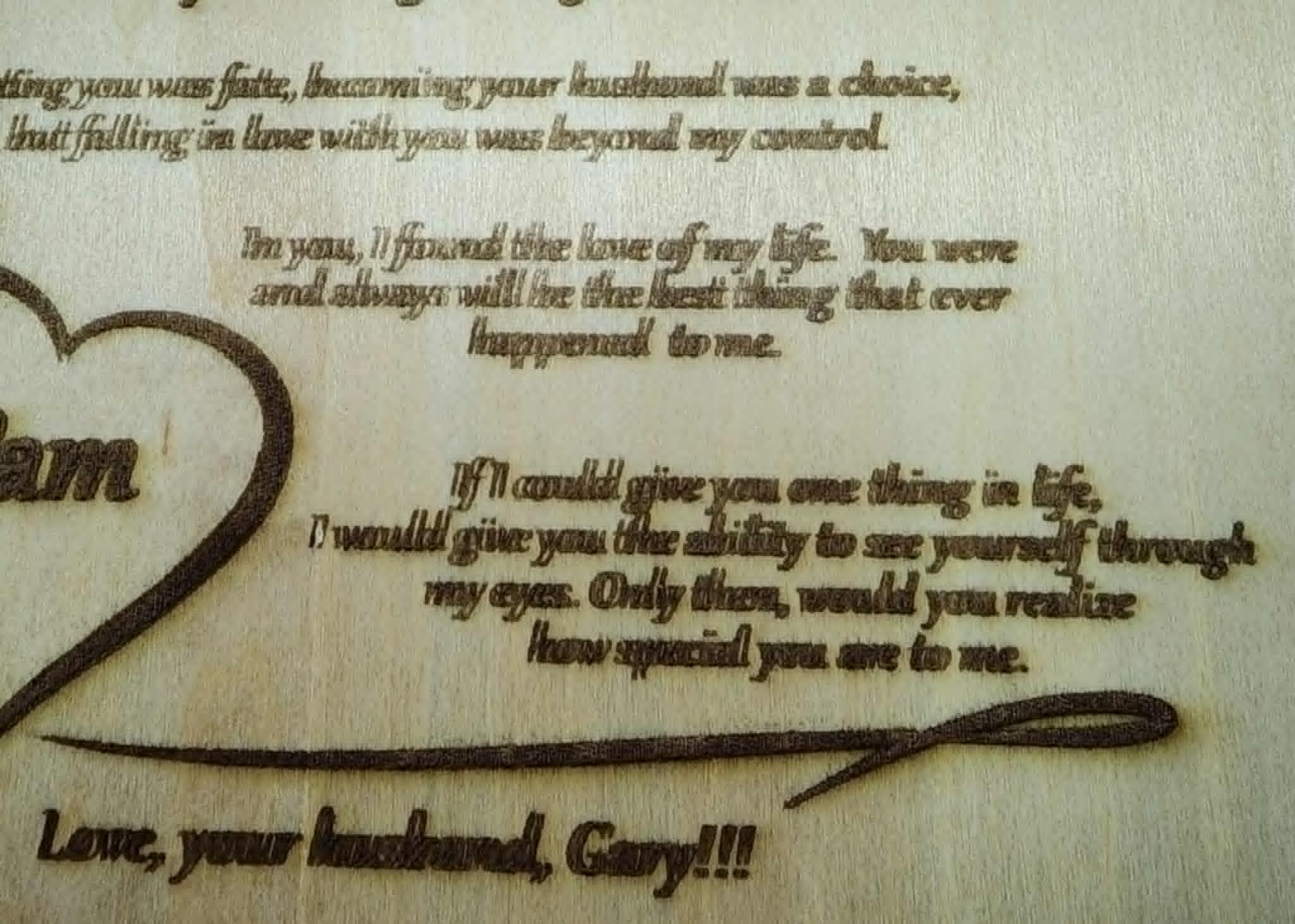

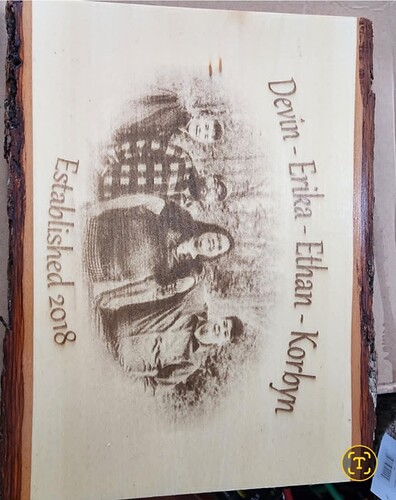

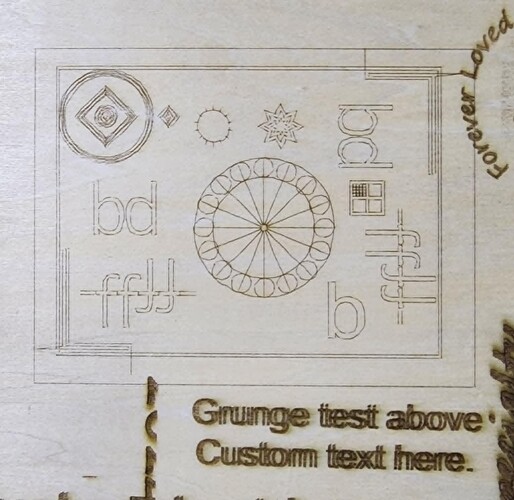

I have included three images: One is what we did a few days ago that turned out very nice. The next one is text only that we did today that had double lines. The third is the Grunge test with our custom text next to it. It seems that any custom text we enter doubles up but if it’s a LR focus/grunge test, etc, it does not double. Thank you for any advice you can provide.

You have play in your machine. See the following. Pay particular attemntion to the set screws on the pulleys as they seem to be a common problem.

A few points to check:

-

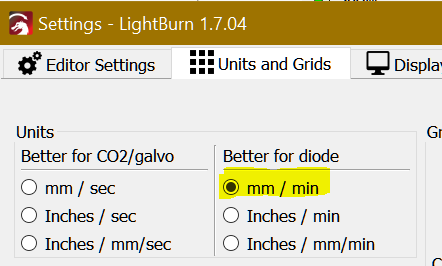

Check if your speeds units are set to mm/m

-

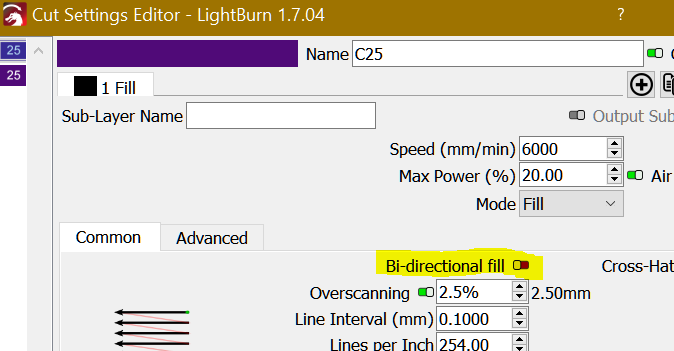

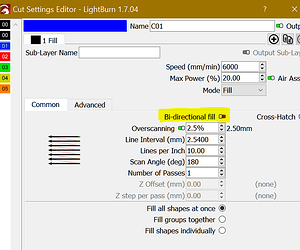

Disable bi-directional fill/scanning.

-

Check for mechanical play.

.

At the end run again the test file in a cheap piece of cardboard.

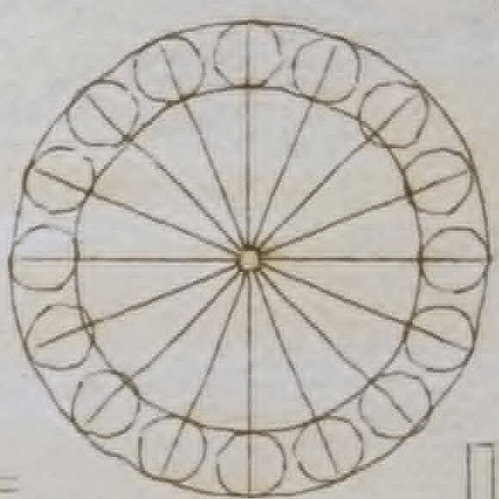

The uneven circles, gaps, and overlaps in this pattern reveal considerable play in the axis drive trains:

Although this photo is very low-res, the same problems appear in this pattern:

Until the machine can reproduce those patterns without errors, twiddling the software settings will simply divert you from the real problem.

Use up plenty of cardboard and don’t stop until it works …

Sadly, this did not fix the issue. We are still seeing clear lines when we do the Grunge test but when we add our own text and etch, it gives shadows/double lines.

Thank you. To clarify, the answer is to adjust the axis points on the actual machine?

Post a picture of the output after you corrected the mechanical play in your laser axis.

If it´s OK a few more things to check:

- Lower speed 2000mm/m?? 20%?? power?

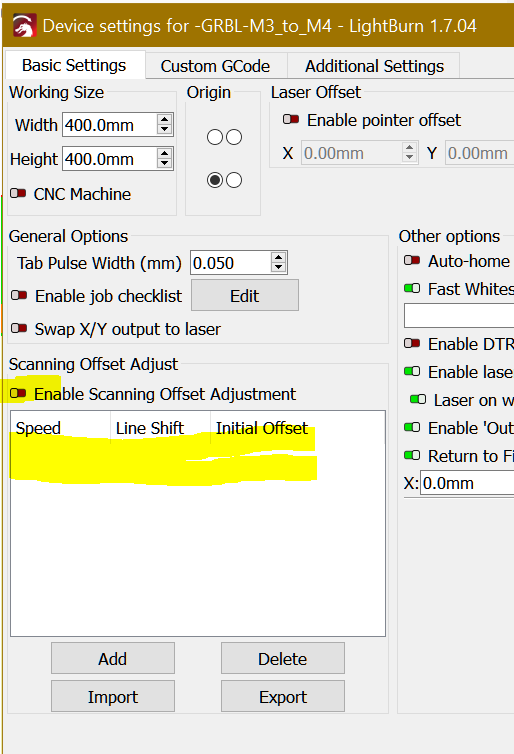

- Check your Scanning offsets, Initial Offset 0.0?

3.Disable Bi-directional fill.

There are (at least) two problems:

- Mechanical backlash

Scanning Offsetcorrections

Unless you have fixed the problems I pointed out in the picture, the machine has mechanical backlash.

When you’ve found and fixed those problems, show us a good picture of that test pattern so we can all celebrate. ![]()

Then and only then you can proceed to the Scanning Offset adjustments, because those depend on a machine with dependable motion.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.