Whats the effect on different Lenses on Fiber Lasers like the cheap 20/30W models found all over?

I got my 30QS Raycus with a 175x175 lens and cant even touch copper at all, but have seen people engrave and cut copper with just 20W models.

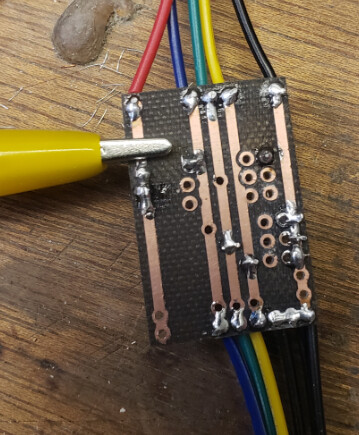

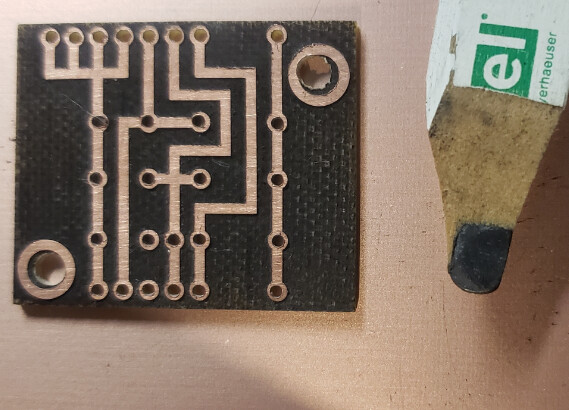

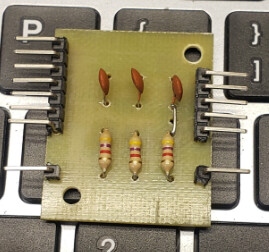

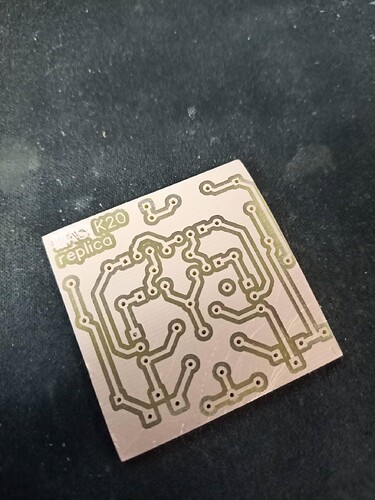

i managed to cut a 2mm steel washer with it, but even 35µ copper pcb material wont work the slightest at a 100% power, 100mm/s

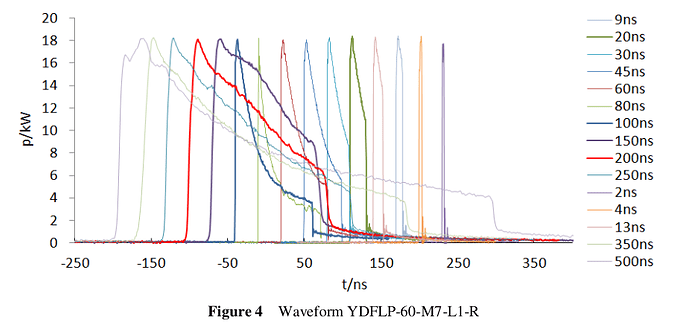

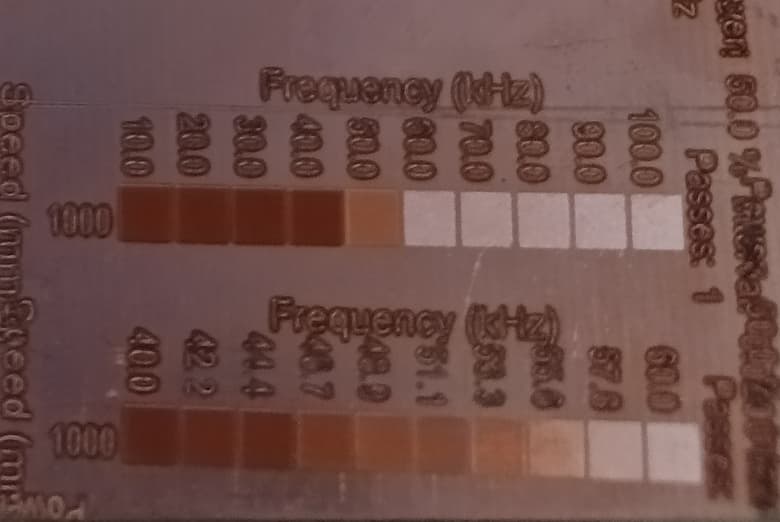

i know, its also pulse-energy dependend to push it over the limit where the material suddently becomes less reflective… as my model only has 0.75mJ per pulse according to the raycus datasheet, some 20W models almost have 1mJ at a lower repetition rate.

But from my old diode days i still know, shorter focal lenghts result in a smaller spot size which increases the watts per mm2 significantly.

So how much more capable is a lens with a smaller working area like for example (extreme case) 50x50 with F=60mm compared to the 175x175 f=254mm?

I also have seen theres different lens materials like K9 and Quartz, is this only needed for higher power models or do the much more expensive quartz lenses perform better?

same as diode days experience with glass/multi element and G2 lenses that made a big difference as they absorbed some of it themselves.