Hello, is it normal for a brand new EFR X4 100w, to cut 10mm cast acrylic with speed 3% and power 99%?

Anything faster or lower power wont cut it. Also get not vertical cut

This is an alignment issue… it’s likely causing the poor cut ability.

![]()

The tube was stored for 12-14 months. Is there any possibility that this wears the tube?

Always a possibility, but doubtful.

Have you checked the TEM resonance mode? That would be a good idea…

![]()

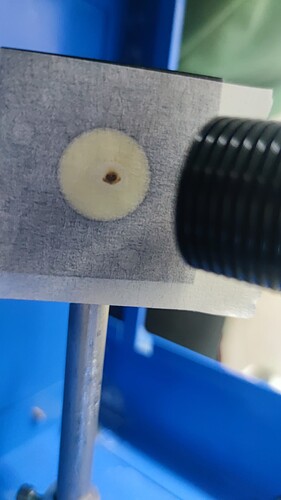

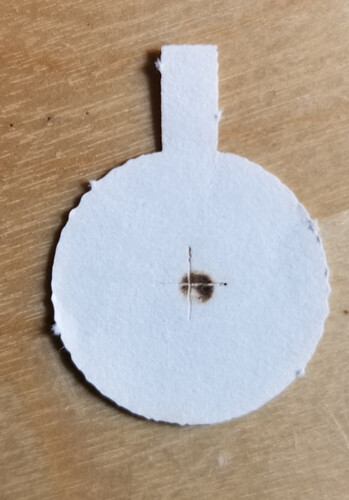

So as I understand, only TEM00 pattern on mirror 1 is acceptable to have good laser tube?

Got 3 pulses on first mirror. One looks like Tem00 but the other two look like Tem10

Is this a reason for low power?

Yep… nothing you can do to fix the resonance.

If you look at your first post, it’s pretty clear it’s failing there. Besides the fact the center area isn’t round … the two tails that I’ve marked should not exists… this is power outside of the beam.

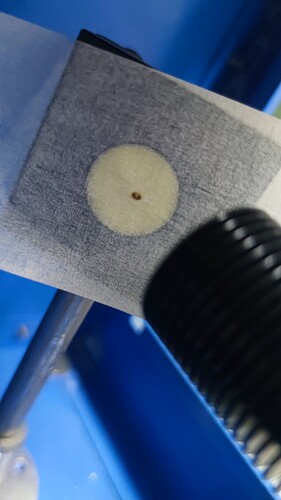

This is the ideal power distribution… Dark in the center (higher power density) and lighter as it moves outward. All even…

Sorry about your tube, bearer of bad news is never good… at least it wasn’t a surprise.

Good luck

![]()

Soyou think the tube was bad from the beginning or got this after 1 year sitting in the box?

And this means that the tube is dying, or its weak because of the non concentrated beam?

Possible… less likely if you live in the N Pole than at the equator… I think a lot of shelf life is ambient temperature… If it’s been this way since you got it, what would you conclude?

This effects the amplification part of lAser.

As with most of these, the lens is actually the most important part.

A lens on your machine is like a camera lens. So if the power is not distributed corrected, it can’t be pinpointed correctly. This results in a vast amount of power loss at the focus point… your focused dot looks like the input beam, just smaller. Just like a picture looks like the real image, just smaller.

Make sense?

Probably a good time to contact the vendor and see if they’ll replace it. Send them the photos.

![]()

Thanks. So the first thing to check when receiving tube is the beam. Now i learnt the hard way. Probably they sent me B grade tube

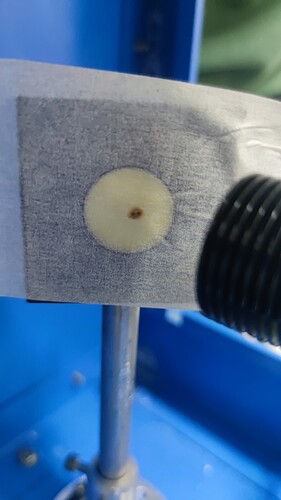

I went off on a three day weekend, when I came back it just didn’t perform on my test piece… It had going out of TEM00 mode over those three days…

I ordered a tube from Cloudray and tried to live with it… One day I must have done an alignment four times…

This was mine, perfectly centered before and a nice round mark… after three days it looked like this ![]()

New tube fixed it… IMHO, it varied by the ambient temperature… can’t see how as I have a chiller, but it did as far as I can tell…

If it’s new, I’d try and get a free replacement…

Good luck

![]()

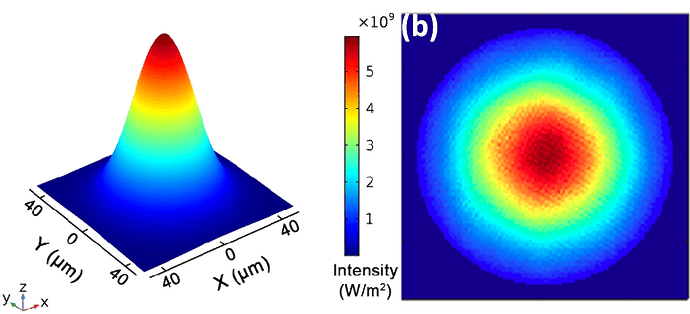

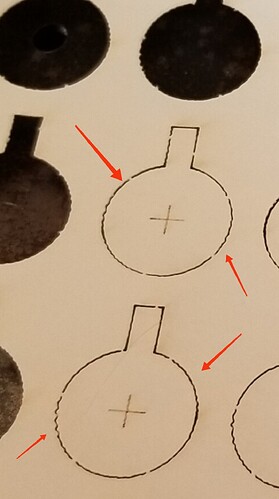

Why this in photo is cut like zig zag?

I see what you’re talking about … Loose belts… don’t worry too much about these… It’s exacerbated by my high acceleration and I run it on the edge.

I usually go over the machine every couple of weeks in an attempt to keep everything adjusted.

They fit in the hole, at the time, it was my only concern, so I finished the project then fixed it.

Next time I cut out targets… I’ll be more aware to check it before producing a hundred of these ![]()

![]()

Just asking because i had some similar zig zag to curves. Do you think it’s from loose belts

The circle is 4mm

Most likely… this is the stuff that generally works loose or stretches things… There is very little stretch in these timing belts, but I’ve had to adjust mine a few times… Worst thing is, there is no way to tell you how to adjust them… it’s kind of an on the job training issue…

I run mine at pretty high speeds sometimes so it has a tendency to require me to look over it when I get done fooling around with these speeds… It’s mostly academic, as higher speeds you an easily outrun the lps.

![]()

So you think it’s from belts and not from linear guides or step motors?

Also as the post is for the X4 tube, today i installed a analog mA meter. The strange thing is that it doesn’t increase over 22-23 mA. Although first days it was working to 28-29 mA(saw on the digital on the PSU), now cannot pass 23mA. So this is also an issue of low power. I tried to regulate the power supply from the little screw potiensometer but it doesn’t increase the mA. Just decreasing from oposite side. Do you think is tube issue of power supply issue?