Hi all,

I’m not sure if this is a hardware or software issue, but I’ve seen this on both RD Works and Lightburn, so my guess is hardware (or a controller setting).

I have an issue when cutting shapes (ornaments in this case), where I’m doing a long-ish engraving of multiple ornaments, then I do a cutout of the ornaments. Many times, some of the ornaments are not aligned properly (engraving to cut). I’ve also seen this with the cut and fill function.

Tonight, I did some tests to see if i can narrow down the issue. I did an engraving test at 100mm/sec, 200mm/sec and 300mm/sec. I set an origin point, pulsed the laser (to mark the origin), clicked start and engraved the file. At the end of the print, the laser head goes back to the origin. At 100mm/sec - the head did not return to the same place, it was about 1mm to the right in the X axis (gantry left to right). The Y axis (front to back) was aligned. At 200mm/sec, it was about 1.5mm to the right and 300mm/sec, it was dead on. It is repeatable as I did 200 three times and 300 twice. In all three cases at 200, the gap was the same (about 1.5mm) and both times at 300, it was fine.

The controller thinks it’s in the correct position (based on the numbers in the controller and lightburn) after the engrave. If I reset the controller, the head goes back to the proper spot.

Here is what I’ve checked so far- the belt seems properly adjusted- snug, but not too tight. I’ve cleaned and greased the rail bearing and have marked the stepper motor sprocket where it press fits on to the stepper motor shaft to see if it’s slipping (it’s not).

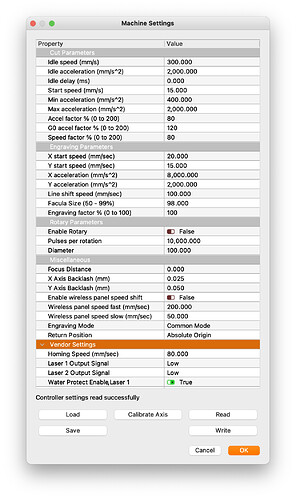

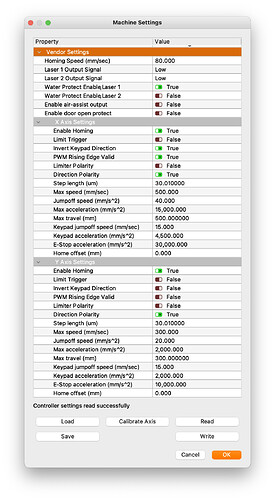

I’m running a Ruida 644XG with RDLC-V8.00.50

Hopefully the experts here have some thoughts on what to check next. I initially thought it was a mechanical issue (slipping or something), but I’m thinking software or controller settings now.

I’ve put some photos of the cut path, the layout, controller settings and a pic of the before and after pulses at the three speeds. Thanks in advance for any help.