The below engravings are from the same file, the only setting that was changed is the power.

The 80w produces crisp edges, while the 130w results in a slope.

Any ideas?

The below engravings are from the same file, the only setting that was changed is the power.

The 80w produces crisp edges, while the 130w results in a slope.

Any ideas?

The 130 W pictures look like the machine does not have good Scanning Offset Adjustment values. Have you measure the actual offsets at various speeds & filled in the table for that machine?

I’ll endeavour to review and complete this adjustment asap. This is another example just for the record. It definitely looks like a power ramp rather than scan offset, however I’ll review to be sure, thank you.

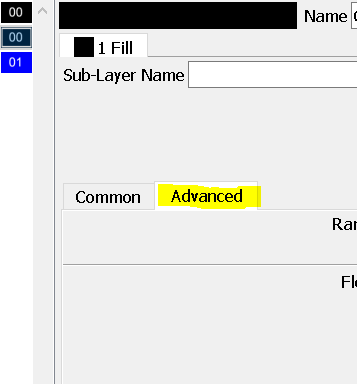

Post a screenshot of your advanced cut settings

Do the Scanning Offset measurements on something like cardboard, set to just barely mark the surface, with a 0.5 mm line interval and upload the pictures so we can see the results.

There is something else going on in there, but we don’t have enough evidence yet to pin it down.

I think he’s moving too fast and the tube is taking time to start up, that would explain what looks like (and is) a ramp … and the brown color on the ramp.

@ednisley can double check, but a quick computation says at 300mm/s and a response time of 1mS that comes out to 300x0.001 = 0.3 or about a 1/3 of a mm in distance to lase. How long is the ramp?

Looks like it has a mechanical component… By the variance in line width, I’d suggest they double check to ensure everything is tightened or snugged up properly…

It’s always a drag to have multiple issues at once. ![]()

![]()

Is it scanning left to right… you can tell in the preview, if you don’t know.

Clearly different on one side, seems pretty clear it’s not turning on quickly enough, even at 200mm/s… it would take 0.2mm or movement distance to turn on.

Can you tell how wide this anomaly is on the left of the single direction scan?

![]()

Is it scanning left to right? It would have to be…

![]()

Yes, left to right

I think you have a big delay in the tube starting up… could be tube or lps… I’d suspect lps…

That’s exactly what it would do. The pass/fail for an lps is 90% of the placard voltage in <=1mS.

I’d expect, at 400mm/s something around 0.25mm, distance wise.

![]()

The Scanning Offset looks just fine, but the startup end of all those lines is terrible: something else is wrong.

It looks like the power starts up just fine, but the focus seems wrong, which suggests the tube is not starting up in TEM00 mode.

Set the console for a manual pulse:

Put some paper / white cardboard target at the entrance aperture of Mirror 1 and fire a pulse to mark the target. It should produce a distinct mark, not burn through, with enough detail to see the beam shape. Fiddle with the power as needed to get a good mark, but leave the duration alone, and post a good picture of the result.

Is it a new-new machine or just new-to-you?

![]() , you need a new tube …

, you need a new tube … ![]()

![]()

I believe the bulb is new! Replaced under warranty on 18th April this year. I think I’ve done three hours on the machine due to issues we are currently working through.

Get an email out to them asap…

That would be sweet news.

![]()

Well, IMO a working tube will get you pretty nearly the entire way to the goal …

It’s also another tickmark in the “check the new tube to be sure you didn’t get a dud” row.

The technicians who installed the bulb did perform some check, however, I do recall the shots were taken at a higher power and longer ms duration. Have sent an email. I’ll come back with how we get on - thank you all, as always.