I strongly recommend you evaluate these burns under a microscope, rather than general overall appearance.

The key points to look for are the line interval spacing, and how the burn is going. If you’re running too much power too fast, you can blast the titanium dioxide off the melt zone and only get the tile a little gray in the melt zone.

I also saw where it was running too fast and the titanium dioxide did turn black, but I could see it didn’t actually get through the thickness of the paint and melt the tile surface. It was black but not glassified.

Hitting with too much power can also make a halo of non-glassified black around a mostly white melt zone.

Sometimes these deceptively appear good, or “close”, or even “great!” to the naked eye but the black falls off with cleaning. This also sucks because small test burns on a prepped tile can’t be cleaned individually after each adjustment, because the solvent isn’t that specific, it will ruin the prep for the whole tile.

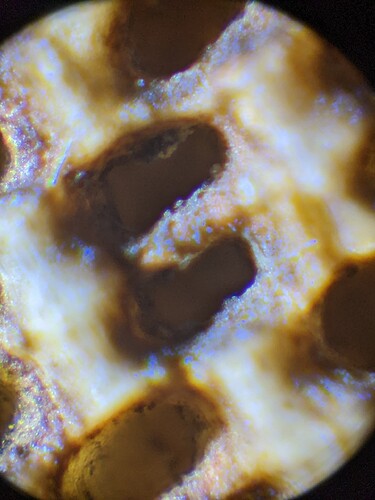

Also if it’s overpowered, you can drill tiny holes in the ceramic surface which may appear as a light image, but isn’t NWT. This actually can appear good when black pixels are isolated, but where it exceeds 50% black or so the black pixels on one line are often adjacent to black on the last line. When that happens, the thin wall between them will collapse and it can go different ways- it can break off and look whiter there, or melt and puddle into adjacent lines and that might appear darker there but it’s not a linear response.

All the while, tweaks to power and speed do affect the spot size and thus line interval must change.

The microscope is such an indispensable tool to understand what’s going on.

I do recommend burning a gradient, like 2" wide 1/4" tall. Let’s say white is on the left and black is on the right.

First run in grayscale mode with too high of a max power. The gradient will show the effect of increasing power so you should see where it didn’t penetrate the TiO2 into the tile on the left, and where it blasts off the TiO2 and creates a melt zone in the tile with little pigment, and/or where it’s got far too much and blasts a hole. You will also see how lines are affecting other adjacent lines.

If you find a black glassified melt zone 1/4 from the left, multiply the max power by 0.25 and use that for the next step.

Step 2 is change to a dithering mode and confirm the black melt zone and the line interval. The process does things quite differently when there’s one isolated black pixel vs multiple adjacent horizontal black pixels on a line vs black pixels on vertically adjacent lines.

It all shows up on the test gradient, time-efficient and shows the whole dynamic range so you’re not picking through an image looking for a spot where there’s a lot of black in one spot. And it’s a slow process so there’s a real limit on how many whole test images you can shoot in a day.

I did find 91% isopropyl alcohol wipes off the dried Bullseye 123 and Krylon primers. This doesn’t dissolve your gloves or evaporate so aggressively, also cheaper. I recommend 91% iso over acetone.