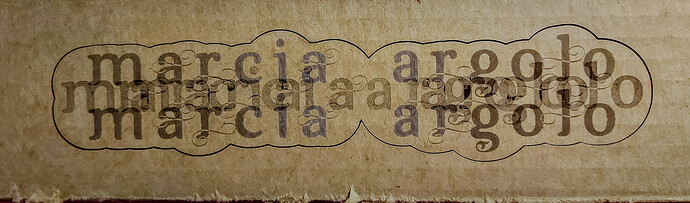

I was doing some test engraving and cutting cardboard as a test, and depending on the font, the words printed correctly or printed overlapped 4 times… one above, one below, and two slightly over the other.

as the error only appeared with a couple of rare fonts I have (didn’t keep the names, but I can go back eventually if this is a matter we should go deeper) but not with normal traditional, I image there is a bug interpreting some font families…

just curious if anybody had similar errors.

UPDATE: further tests showed me that the problem is NOT with a particular font, but it is a FILL problem… it gets worse… sometimes I get a duplicate, sometimes I don’t.

I need to verify if when I did tracing, I did remove the extra drawings that I read somewhere that you have to delete…

I need further testing and reporting.

Can you upload a sample .lbrn2 file that has this symptom?

Hi,

Test W fill error - multiple shapes carved.lbrn2 (991.8 KB)

Thanks for the message. attached a sample I had with the multiple shapes filling.

Thanks

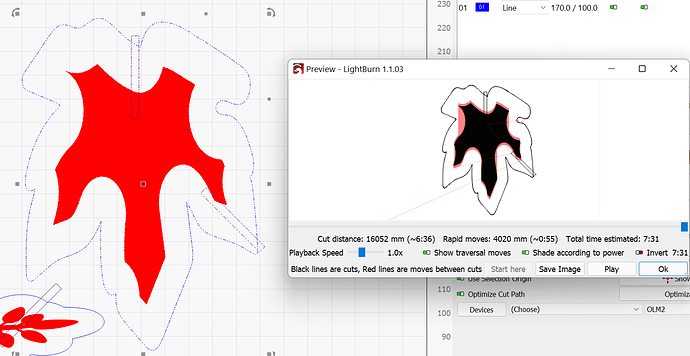

I’m not sure if I’m seeing the problem. The Preview seems to match the design.

Or is it that you’re not expecting the 2 rectangular pieces to burn in addition to the fill layer?

If so, this post from Oz and the Topic in general can help you understand how layers affect the interpretation of the design.

I’ll send you pictures tomorrow… it does not show any problem in the screen, ONLY when you burn it.

I’ll send you pics tomorrow.

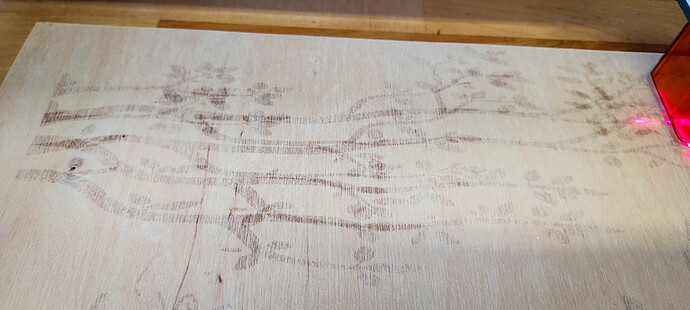

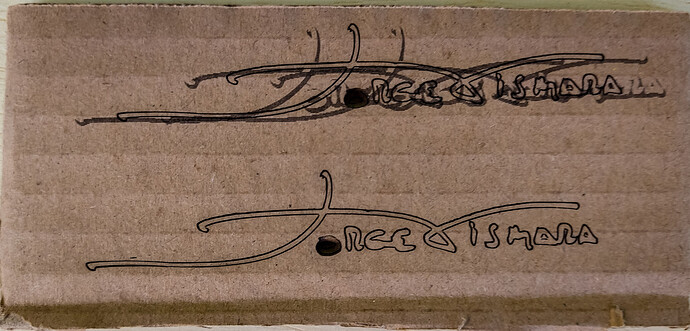

here how it looked after I did a couple of LINEs to try to have a feeling of what I wanted.

Also there is a picture of the other piece in the file. Also I included one of the first problems I found that I thought it was the produced by the font.

ALL of them looked OK on the screen, but not when burned.

Looks like you’re missing steps. I would first guess from belt tension being too low. Do a mechanical review of your machine with a focus on belt tension. You want to remove all slack from the belts. They should be taught without being stretched.

LightBurn team recently made a great video going over many of the common problems with diode lasers. Check it out here. They talk about loose belts and other problems. I suggest you focus on the mechanical issues for now.

your sample does not match the error I’m reporting.

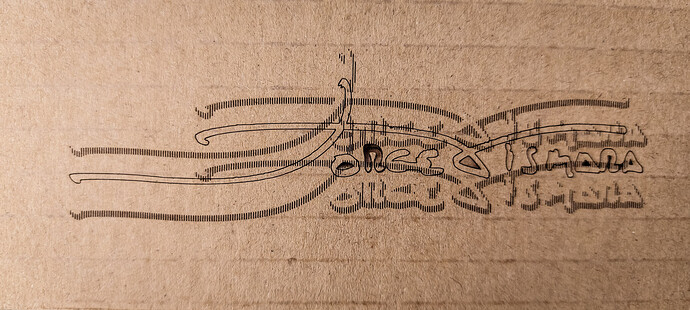

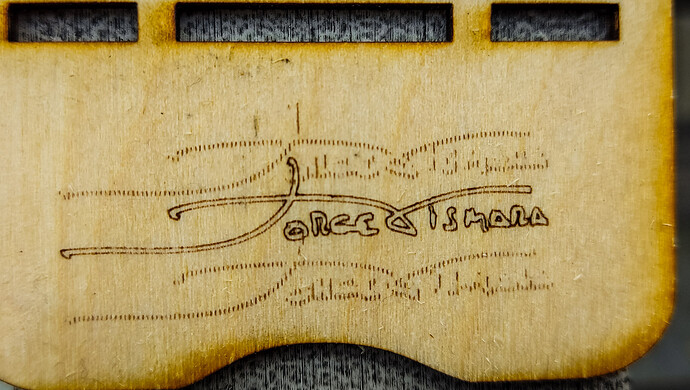

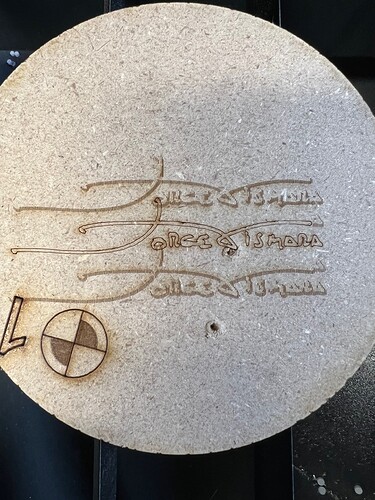

here a simpler example: my signature… sending three files, two photos and the original lbrn2

burned on wood and cardboard.

the FILL makes a double image one above, one below the LINE…

JV signature.lbrn2 (80.4 KB)

I keep testing and the results are similar but different.

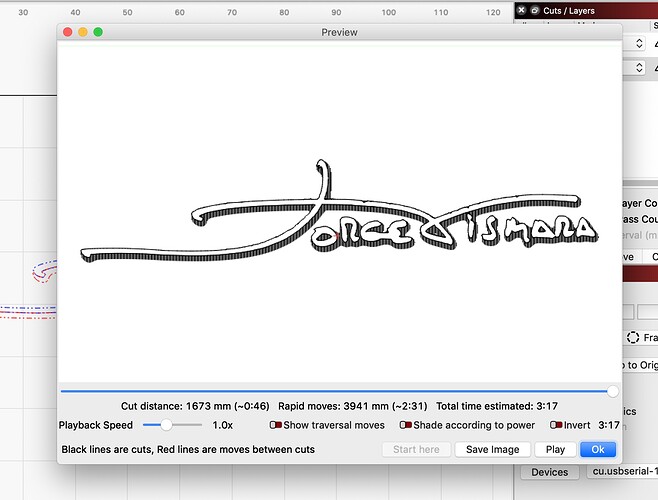

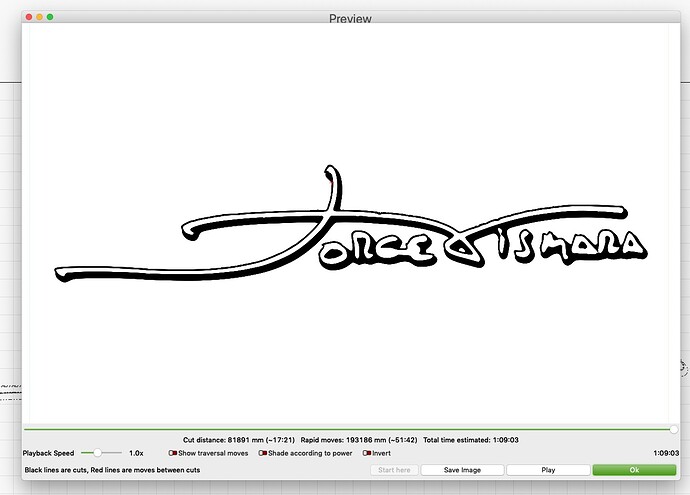

Did a new tracing of my signature.

Created a FILL for the shadow and a LINE for the signature itself.

Look at the burning sample. The top burn was burning both, FILL and LINE, the bottom burn was burning ONLY the LINE.

We can see a new duplication of the FILL, shadow, but this time is horizontal.

My guess is there is a problem or either on the Tracing routine, or the FILL mode, or on both.

This is NOT a problem with the Xtool D1, as the error can be different, after a new tracing.

Here a copy of the photo of the burning and a copy of the LBrm2 file.

JV signature 2.lbrn2 (115.0 KB)

Not following how you came to this conclusion based on the evidence.

What you’re seeing are not duplicates. They are misaligned components of the same design almost certainly caused by missing steps. And again, most likely from loose belts. Did you review the belt tension?

The other thing I noticed was that your speeds on the line and and engraving are quite fast, especially the line. This will cause any mechanical issues to be more pronounced.

Try dramatically slowing down your line and fill speeds. If things improve this reinforces that that the issue is from skipping.

no way… can I speak with your supervisor?

Not sure that would be a benefit as my wife doesn’t know much about lasers or LightBurn.

But perhaps one of the other fine folks on this forum would be willing to help you going forward though. I suggest you provide an update on what you’ve tried of the previous guidance as that will help move things forward.

I thought I was getting comments from LightBurn tech support… didn’t know you were just another end user.

I have some experience with software development (system analyst developing SQL databases for 30+ years), and mechanical understanding of the basics (change my own transmission some years ago), so I have some base to say what I’m saying.

So on the XTool website it mentions control software: laserbox. And also says Lightburn But I didn’t see any other pages describing it. If Lightburn has issues controlling this machine are you able to try laserbox?

What berainlb is saying is that we aren’t aware of any Lightburn settings that would cause your problem.

@jvismara I just ran both files you provided above on my laser here with the only changes being made were to speed and power to be appropriate for my laser see results here:

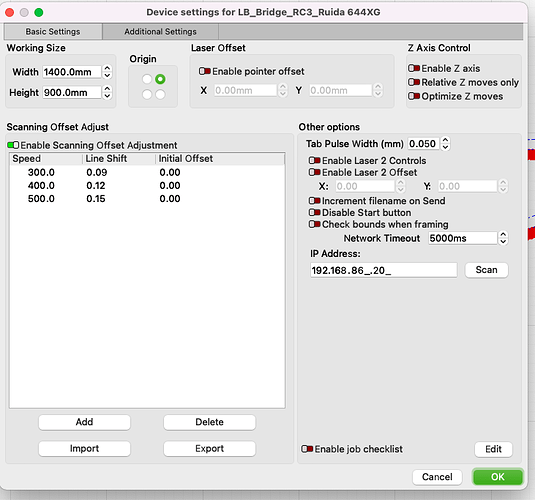

So I think there could be a couple things happening here. The first and I think the most likely is you have “Scanning Offset” enabled in device settings. This would explain the double image you are seeing on the scan and why its tracking with the direction of your scan. You probably do not need this at all with the xtool. Learn more here: Scanning Offset Adjustment - LightBurn Software Documentation

Next, your acceleration may be too high causing missed steps, but since its tracking with the whole file and not erratic I do not think it is that.

ALSO - the dev’s and support staff are here. We are few and you are many. We read the ENTIRE forum. If we don’t answer your question in a day or two feel free to bump the post or send an email to support@lightburnsoftware.com. The end users here are very knowledgeable and are often able to solve problems before we even see them.

I have posted a problem and several updates on a burning error, and have had ONLY answers from a person identified as berainlb that doesn’t really understand the problem, and offers weird recommendations.

Here is the link to my post:

Thanks

As @JoeSpanier identifies, we are here along with a bunch of very smart and capable members offering to assist you. Please let us know how you progress and we can continue from there. ![]()