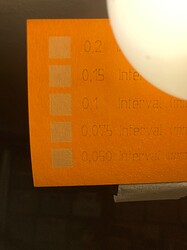

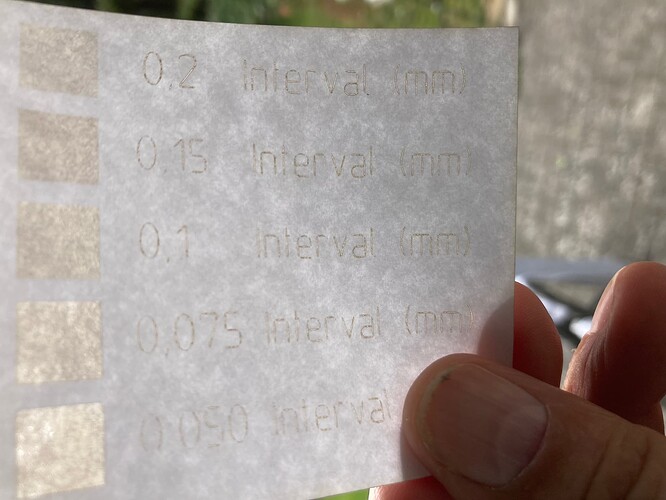

If all the other ideas fail, you might check out the speed you’re attempting to do this and also take into account spot size of the machine. Interval is very much related to spot size.

A shorter lens will give you a smaller spot, all other items being equal.

Most of these come with a 2" lens (50.8mm) that produces a spot size of about 0.205mm, based on a 5mm input beam. You will find it difficult to produce an image with any resolution of greater than ~124dpi (0.205mm interval) if your spot size is the 0.205mm assumed here.

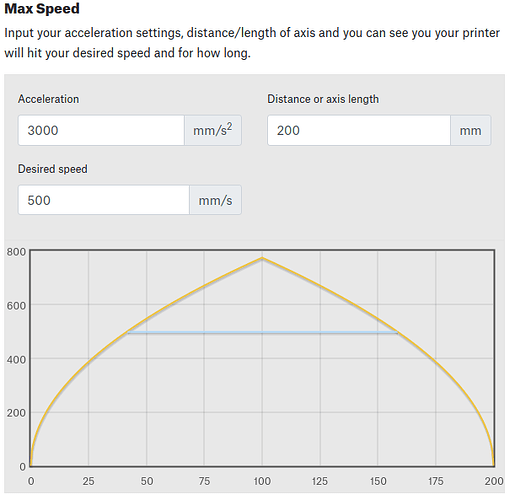

If you are doing small vectors as some have suggested, you likely can’t reach such a high targeted speed in such a short distance.

You can see the value set and the distance required to reach this speed, which is almost 50mm. If you are doing an image or fill, this will be the overscan.

The acceleration values on your machine could be different, resulting in different results.

Your glass tube/lps has a response time, usually, <= 1mS to reach 90% placarded voltage.

Worst case, is that at 1000mm/s, you cover the 1mm distance in 1mS. Turn it on or off, requires 1mS or 1mm in distance.

The best resolution you can expect to achieve, and still be in control of the lps is 25.4dpi.

Slow down to 500mm/s and it doubles the possible dpi to 50.8. At 250mm/s, it again doubles it to 101.6dpi

My machine will run 1650mm/s, but most of my engravings are using speeds below 300mm/s.

If you use minimum power, you might want to check your Ruida Start speed to ensure it’s low enough. If not the output when the speed is <= to the start speed, then you will only get minimum power.

Good luck