Having problem with x and y axis alighnment and knid of fixed but now i can not set the farming problem can not get it right to farme the object on work space it frame longer the object any idea why and how to fix it on ATEZR 35 W LASER ?

better you post here some picts and the .lbrn file to let us check

Continuing the discussion from FRAME PROBLEM with ATEZR 35 W LASER:

Your drivetrain (motors, pulleys, shafts, couplings, belts) needs gone over carefully to check for loose fasteners. I had quite a few loose fasteners, including motor mounting hardware and linear rods on both Y & Z.

Assume the factory screwed up EVERYTHING.

i agree with @cggorman you need to check for belt, pulley and motors. Then we look at speed of engraving

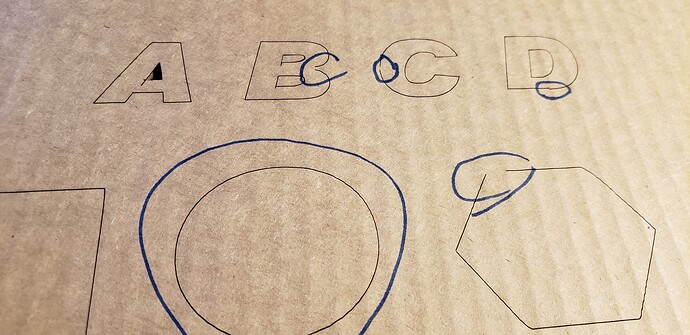

Thanks you guys i fixed the issue but still have one issue that is driving me carzy which is my machine dose not cut a perfect circle or octagon what should i do to get it right .

Thanks

What was your fix? Posting a resolution helps others who search in the future.

Pictures, settings, dimensions, etc. will be required to diagnose further.

Might be axis calibration, rotary settings, more mechanical issues, cut/layer settings, etc.

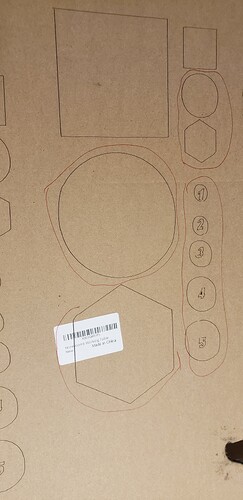

i did readjust the belt and x y now it dose the right farming but still not cutting numbers or font or any object drawn like octagon squire or ![]() it dose it thinner that on the screen ,.

it dose it thinner that on the screen ,.

The path that the laser takes is shown or illustrated in the workspace and in the Preview window.

LightBurn doesn’t know how a particular material will respond in terms of speed and power. This is up to the user/operator to select because it is a matter of personal taste. Further, material can be inconsistent from batch to batch or even from day to day. These are the is the reasons why developing your own speed, power, and dot-size (aka Line Interval) settings are so important for moving toward success.

I moved the posts that were related to loose hardware ( Set screws and Belts ) to this thread and I’ll offer advice on backlash, mechanical binding, and machine calibration on the other thread.

If things are as they seem to be here, this engraver is rife with mechanical concerns that should be addressed before any software can control the engraver.

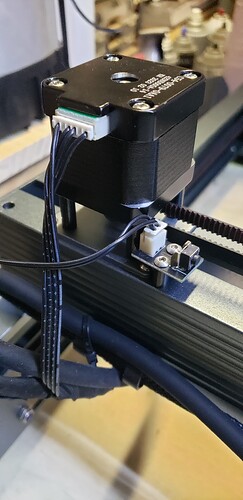

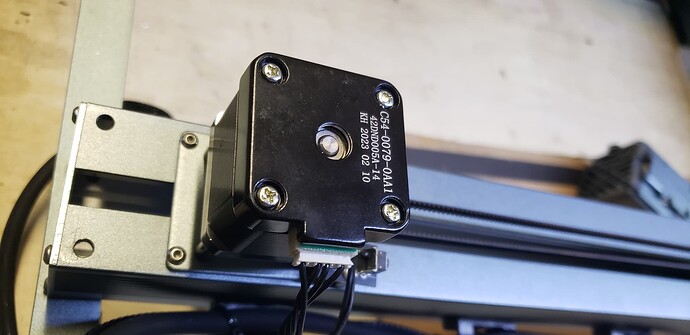

Thanks guys after few hours checking i found out that z axis stepper motor is frezed and not moving the belt i open it looks like there is plactic gear inside that is strriped and pully is not turning the belt and the beeps sound is the gear not enging so i am f… can not find the parts on line and the company dose not have any iformation on this part . love the machine but no support.

Z axis stepper with pulley? Only the L2 model has a Z axis stepper and it has an integrated lead screw.

Can you upload a picture of your machine and the problem part, please?

Thanks chirs i think my machine is gone even the laser is not firing so it could be the controller is gone as well with stepper .i can hear the buzzing on the stepper butthe gear is jamed .

Anything is possible.

That looks like your X axis.

Did you try to change $100 back to 80?

$100 is the step count for the X axis. I have no idea what would happen if you try to send 94,000 but it’s certainly worth returning everything to default before spending the next month fighting with Atezr for a replacement machine.

The easiest way to do this is to simply type “$100=80” (no quotes) in the console, then hit enter.

Thanks Chirs i did try 100=80 it looks like it did work thank you so much but it dose cut very strange and object is stratch not right so i lave to play with againe circle is like is not round l

80 is just a starting point. Unless you know the original values, I suggest you set both $100= 80 and $101=80. That way you can evaluate the mechanical situation. Once the machine is making circles and squares reliably, then you can worry about axis calibration.

The difference between 80 to 81 is fairly significant. That alone may get you close to proper squares and circles.

Thanks Chirs you rock now the head is moving and laxer working so where should i put the values in console. Hope we can fix the starch problem have to play with it when i get home is tha possible to have a phone conversation so may be you can help to do it right i was going to give up on this machine and buy an other one but now have to work on tuning the machin .

Thanks

You can type the $101=80 into console.

Just take notes and make one change at a time so you can observe the effect and revert back if necessary.

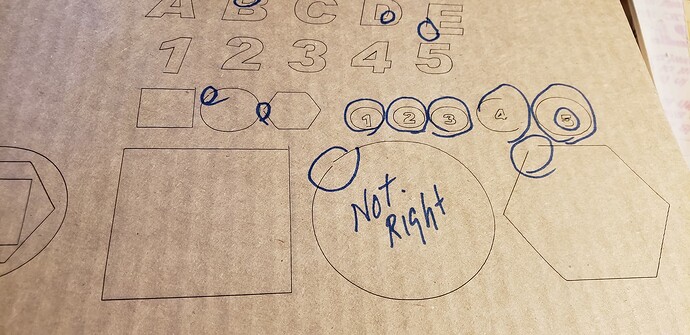

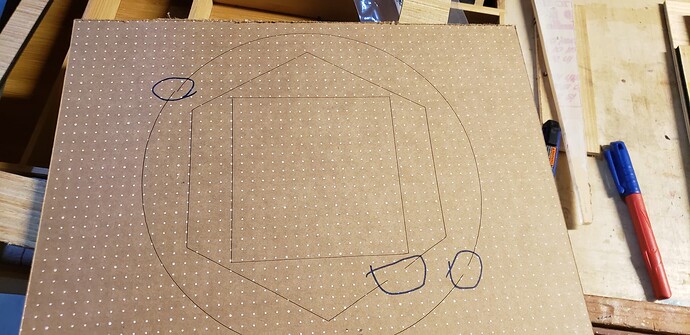

Thnaks Chris you help me alot and i got the machine running with some adjustments on rails now it runs smooth but i notic the laser cuts off some area that dose not cut thrui did some test cut which i send you to see and see what i can do for some reason the bigger scale dose better thank small and circle still is not 100% round .

Lets see if @misken has any input on this…

It seems like both X & Y are behaving erratic. I’m tempted to say it’s missing steps from things being too tight, but I have zero experience with a machine of this construction type.

The whole mechanics is still very wobbly. The open circles are just a result of the laser not returning to its starting position. The numbers also don’t look good, as far as I can see.

Check the steps per mm value again, to make the rectangle be a square / the circles round. But this has nothing to do with the backlash problem.

First, check all belts, wheels, and gears. If you touch/push the motor while not moving, does it feel stable?

Next, what speeds did you use?