A typing error! Both passes were DPI because I was using an image using threshold, which just means black and white. It was easier than tracing the image and filling in all the small areas. I made another “experiment” today. I’ll post a photo later.

An old address from years back. A terra cotta tile. Various LPI but all burnt as before at 500mm/min at 95%. I’ll cement it into place one day.

I never thought about using that material. Interesting!

However, I would be a bit reluctant posting ,my address on the internet.

Mix with denatured alcohol:

Dilution Ratios

Spray On: 2:1 (2 parts alcohol, 1 part CerMark)

Brush On: 1:1 (1 parts alcohol, 1 part CerMark)

That should sinter it damn well…

Seth

[1] This alcohol is flammable. Please use caution.

[2] Unless you are trying to get more mileage out of the Cermark, why dilute it?

[3] Would acrylic white not do just as well?

[4] @Mito did not mention any coatings. Have you tried doing terra cotta?

Right…caution!

Alcohol is flammable and you will only want to use it on non-flammable surfaces (NO Galvo Fiber) and mostly baking the Cermark and Denatured Alcohol on metals…

Cermark used to recommend the dilution and mixture with their dry products.

And…one would need a chamber that has a fan to suck out the sooty residue while engraving along with a compressor as an air assist.

Seth

There is no “additive” on the burn. It is raised above the surface. It’s not obvious in the photo but with lower LPI there is a flecked effect with the orange showing through.

Whatever you did, it still looks great.

So, I was thinking… The difference between the polished rocks from Lowe’s and the unpolished rocks from Home Depot made a huge difference in contrast, and the lack of contrast was a big deal with the rocks in a pack of “painting stones” I bought to try out. Well, I’m not going to get a rock tumbler and spend weeks (and significant amounts of electricity and various polishing media) polishing them. On the other hand, perhaps I don’t need to polish them at all…

Well, since I happened to have the dregs of a can of spray lacquer handy (thanks to the Melrose cut-and-paste sign), I figured I’d give a set of rocks a spray on one side and leave the other side untouched, then engrave both sides on my fiber laser using the exact same settings, which I pulled from a previous rock job (3000mm/s, 70% of my 60W, interval 0.05mm, 80kHz, 200ns, 10 total passes).

Here’s one side of five arbitrarily chosen rocks, engraved without anything special. (The bottom right one I’d previously engraved, but I figured that would be good enough.)

And here’s the other side of the same five rocks, this time after a quick shot of spray lacquer (which I allowed to dry, of course – that stuff’s quite flammable).

So, the top right rock didn’t really improve – it may be better uncoated. The top left and the center both showed notable improvement, but they’re still not my favorite. (The center, especially, might be fun to paint black, engrave, and then lacquer to bring up the saturation.)

The bottom two rocks, on the other hand, were drastically better with a bit of spray lacquer to bring up the background saturation and therefore the contrast. I think I might have to spend some more time with this box of rocks.

Interesting experiment. I too found a lot of variety in the rocks. I found painting them with clear nail polish (that is all we had here) made a substantial improvement, but again only with certain rocks.

You are not lasing any alcohol. If you’re using LBT100, Cermark or Brilliance coatings, then you’re not using it correctly or, maybe you are, but don’t realize it.

There is no alcohol left when you lase these coatings, so any worry about alcohol should occur when you’re applying it.

You will breath this stuff under most circumstance and I suggest you use Ethanol for the alcohol, if you have a choice. At least it’s not as toxic to you as other alcohols.

![]()

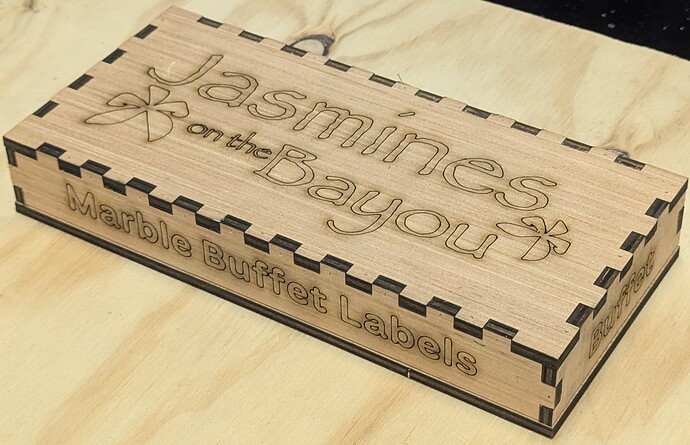

My wife’s gearing up for the big Mother’s Day Brunch Buffet at Jasmines on the Bayou (the only Sunday they’re open all year). She gave me this year’s menu last week so I could update the pretty one I’ve rendered for them each year (alas, no lasers involved, just a lot of Inkscape). That was easy enough, but it got me thinking. They usually just print out stand-up labels for the various buffet items, but I mean, hey, don’t I have a shop full of lasers?

So, I figured why not try my hand at frying some more rocks. If I ordered one herringbone mosaic polished white marble tile panel, I ought to be able to disassemble it and end up with a stack of 48 marble “labels”, each 1x3". If I then engraved them on the fiber laser and did a quick black paint fill…

It turned out to be quite easy. I peeled them off the fiberglass screen backing, hit them with the laser (3000mm/s, 70% of my 60W, 80kHz, 200ns, 0.05mm interval, three bidirectional cross-hatched passes), brushed on some black acrylic paint (the kind in the tube from art stores), and quickly buffed the polished face clean. I finished them with a just a bit of sanding to soften the edges, clean up any paint on the sides, and take care of any fiberglass threads or residual adhesive.

Of course, if I want them to stick around, I figured I ought to make a little storage case for them. Since the menu changes a bit each year, I made the case with plenty of room for additional marble labels, and I engraved the top (for aesthetics) and the sides (for visibility).

Anyway, here you are, some particularly rectangular and partially shiny rocks, plus a storage case.

Incidentally, the marble tended to “shatter” into grains in the engraved area. Definitely not smooth, but since I was doing a paint fill, I considered that a positive. Also, the more pure white the piece, the less deeply it seemed to engrave. There wasn’t really a noticeable difference in general, but a couple of the pure white pieces were a bit shallower than intended.

Nice work. I like to do “one-off’s”. Makes my day seem better most of the time.

BTW: How many of these sets are you going to make?

Counting this? One. ![]()

I enjoy designing and making things, and while I’m certainly not opposed to making money, the whole process of pricing and selling and all that jazz is something that I actively dislike. (Go figure, the one hat I don’t wear is “entrepreneur”. Drat!) I’ve told at least one friend that if they want to do a storefront/craft booth/whatever, I can certainly make a bunch of whatever and split the after-expenses take, but that’s as close as I’m likely to get to selling stuff.

Conveniently, between making things for my wife, making things for the restaurant she manages (front of house), making things for our local parks (volunteer perks, table flyer paperweight rocks, event award plaques, etc.), making things commissioned by friends and acquaintances, and just goofing off, I keep my hobby self busy. Still, it’d be nice if someone would sell enough of my stuff to add a UV galvo to my shop… and maybe a CO2 galvo… and… ![]()

Seems to me it’d have to be a metal tube co2 to effectively use a galvo. Speeds are limited with a glass tube and most gantry machine can go faster than the lps can respond.

However, I’d take one… either way.

![]()

The CO2 galvos I’ve seen have all been RF tubes, yep. Not planning on buying one anytime soon (or ever), but it’d be a fun thing to add to my collection.

I suppose for now I’ll just have to look forward to the weekend, as I’ve got a mixing tub full of empty apple snail shells waiting to get some time under the fiber laser. I played with some a while back, with unexpected and interesting results, and now it’s time to do a fun project. Do apple snail shells count as “rocks” for the purposes of this thread? I mean, they’re definitely mineral-type material. ![]()

I have no idea what that is, but I found seashells (I am in FL) behave the same way. The 10w diode laser would not mark the white ones, but maybe I need to test with the 40w one. What colors are yours?

Smart! I tried a couple of craft fairs and lost money on both. Anybody need a couple of 6’ folding tables, like new?

Now it is only a little custom engraving to help pay for the inventory of stuff I can’t seem to sell. I obviously do not have the Marketing DNA.

Do you keep the rocks or leave them in random places? I think that would be incredibly fun to do a bunch of them and leave them in public places for folks to stumble across. I can just imagine a child picking one up to find a pokemon or or some other character on the other side. The delight in their faces would be priceless.

I gave them to my family while I was in NY. The rocks that would not burn well were left for them to paint.

I think the scattering idea is just great! The next door neighbors have a girl just the right age. I will have to do that.