I recently took delivery of a 65W CO2 Galvo laser from Finnlaser. I have identified a couple of issues which I notified them about. It is the weekend so I’m still waiting to hear back. However, I think its also worth posting/asking here as the forum has such good resources…

Note specifically that this is a Galvo Laser - and not a gantry laser. I have two other Galvo’s (a 5W UV From Finnlaser and a 60W MOPA Fiber from OMTech) as well as an 80W CO2 Gantry from OMTech. All of these are running with Lightburn so I am fairly familiar with the tech and the software. Anyway…

I ran my first job the other day. Its a raster etching on clear acrylic. However, after running the first piece, I noticed I had a double image about a mm or 2 apart in the horizontal direction. Typically, I do my raster scanning as bidirectional at 0 degrees (horizontal). My initial thought was that there was some slop in the horizontal galvo mirror and it was being taken up as the mirror changed direction.

So, I turned off bidirectional scanning and the issue was no longer apparent. But the job obviously took twice as long…

Out of curiosity, I changed the bidirectional scanning mode to 90 degrees (vertical). Now the double image is in the vertical direction by about the same amount.

Its pretty clear (to me), that the galvo mirrors are changing direction out of sync with the laser pulse. Since this is happening identically on both axis, I think its less likely an issue with identical mechanical “slop” in BOTH mirrors. So, its not really a double image, its just that half the image is offfset from the other half. Odd rows/columns to one side, even rows/columns to the other. (I even ran a low LPI test to confirm this.)

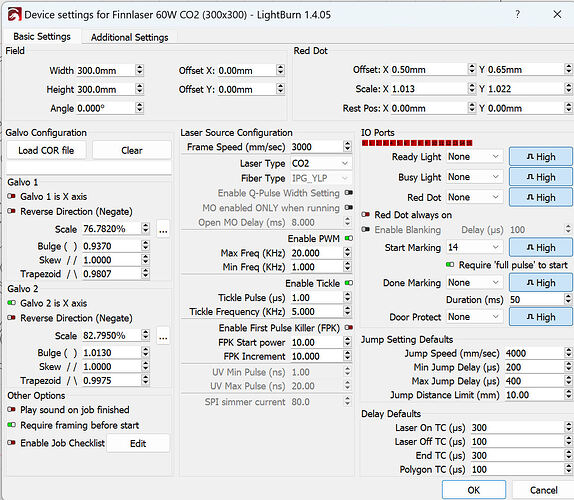

So, this kinda points to a controller/config issue with the laser hardware or the software. Maybe the firmware in the controller is not set properly. Maybe Lightburn needs some other setting (which I can not find). As with all my other Galvo’s, I merely imported the EZCad markcfg7 file into Lightburn to configure the device. None of my other galvo’s behave like this.

This is a SinoGalvo 2808 galvonometer. Its a premium unit and it is supposed to be capable of speeds up to 7000 mm/sec. (I wanted a galvo CO2 laser specifically for raster etching to save the wear and tear on my Gantry laser). My initial job was only running at 1500 mm/sec. I have tested at both 1000 and 2000 and the problem gets worse as the speed increases. Again, I think this points to some timing/sync issue between the galvo head and the laser.

However, I’m not sure where that sync should be taking place. I expect it is the responsibility of the laser controller to handle the sync (surely this is not happening over the USB bus…). But maybe Lightburn needs to pass in some sort of config param for the end of line delay/sync? I’m kinda thinking “not”, but this forum is a good place to ask!

My primary goal is to understand which component is likely the one which is misconfigured/failing. I’m guessing its hardware (controller or galvo head) but not sure which. Anyone got any insight?

Also…

Can anyone familiar with Galvo heads tell me if there should be an adjustment inside the galvo head (trim screw, etc) to tweak the mirrors such that the laser shoots straight down through the lens. At a 450mm focal length, I’m off to the left on the X-Axis by about 26mm. (Vertical seems reasonably close though). As I cut fixtures to mount my jobs on the work table, I can’t have my beam wandering as I move the galvo head up and down (changing lenses, etc).

Thanks in advance!

Ed