Hi Matt — I’m pretty thrilled that Lightburn keep hiring excellent people!

My “60W” OMTech ebay laser is still very new, and it has spent more time in pieces than actually cutting. This is because I haven’t stopped trying to make it better. I’m not exactly sure why I’m compelled to change it, but I’m having a great time. It now has a motorised bed, better fan, compressed air line, etc.

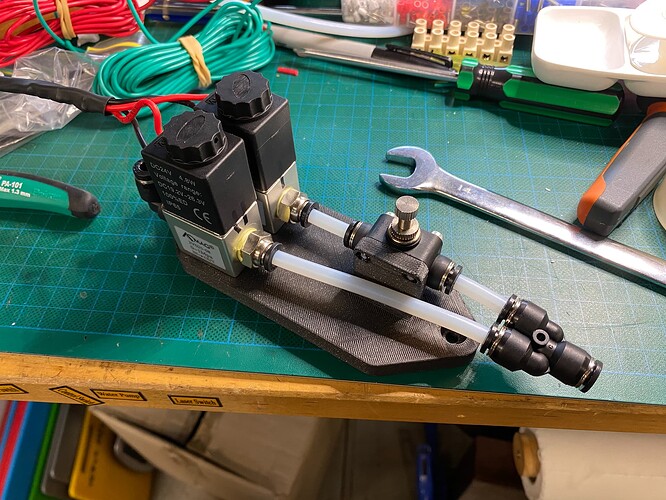

I’m still learning a lot about CO2 lasers, so no amazing laser projects to share at this time… but my air assist upgrade was printed in Prusament PLA, so I feel like it’s extremely relevant to this particular discussion!

The stock machine uses 18mm lenses which are mounted inside the nozzle. I’m converting the machine to a Cloudray head (I think it’s a “Type C”??), so that I can use 20mm 4" lenses for (hopefully) better cutting performance. This has involved making a new bracket to mount the head, which I have made from scrap aluminium. I need to turn some 16.5mm standoffs to get the head up higher, to locate the mirror closer to where the stock one was. My “design” is basically a collection of workarounds, which I am affectionately referring to as “prototype 1” in case it all ends in disaster

I’d’ve done a much better job with FreeCAD and 3D printing — but I’m apprehensive about using too many plastic parts inside the enclosure, in case of fire. Perhaps that is silly. Who knows? Aluminium fabrication is extremely rewarding, I reckon, even though my parts look… pretty scrappy.

I need to change the way I’m homing the bed — I approached it like I would have if it was a 3D printer, where the bed itself hits the endstop. This isn’t great for laser cutters, I’ve learned, and I think it might be simpler to use a probe-style endstop which hits the material itself. Either way works, but the material-detection seems more in-line with how lasers “expect” things to work (currently a long lens/nozzle hits the honeycomb, material detection could help avoid this).

TLDR:, hi, glad you’re here, very excited to be a part of this all. Now back to the laser!! (well, first to the lathe… then to the laser!!)