Hi All and Sundry… Think I have found a ‘magic fix’ for lasering glass. ![]() I know there are zillions of ‘this is how you get good results’ out there - but in my experience are frustrating at best and mean more time in set up etc. I was going ‘distracted’ after yet more ‘poor result - dump in trash’ fail and was roaming workshop clutching at straws for ideas when … there it was , staring at me from off the shelf

I know there are zillions of ‘this is how you get good results’ out there - but in my experience are frustrating at best and mean more time in set up etc. I was going ‘distracted’ after yet more ‘poor result - dump in trash’ fail and was roaming workshop clutching at straws for ideas when … there it was , staring at me from off the shelf ![]() … "No- that is a stupid idea, I says to myself… but, Hey, why not give it a try…

… "No- that is a stupid idea, I says to myself… but, Hey, why not give it a try… ![]() so, when I plucked myself off the ceiling in euphoric disbelief

so, when I plucked myself off the ceiling in euphoric disbelief ![]() I decided to keep my new ‘trade secret’ to my narrow minded and myopic self.

I decided to keep my new ‘trade secret’ to my narrow minded and myopic self. ![]() That was about a month ago and after much travail of soul

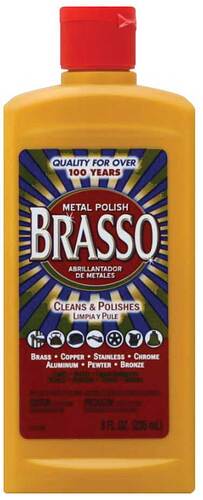

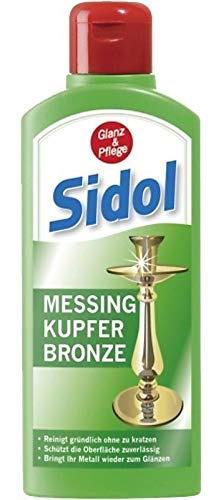

That was about a month ago and after much travail of soul ![]() have decided to ‘release’ the secret out into the open - and suffer the backlash etc after being shot down in flames etc (if doesn’t work for you its not my fault anyway) so believe it or not what I did was smear some ‘Brasso’ onto glass surface. (Actual product is German ‘Sidol’ ) with my grubby little finger - nothing fancy or special, just smear it about for a thinish layer but not tooo thin. As to settings in Lightburn - I have a vector outline of subject and then ‘Edit’ tab - convert to bitmap, then in layer settings used ‘Atkinson’ . Different glasses may need slight tweaks with speed and power for your machine. Well, give it a try - let us all know what happened.

have decided to ‘release’ the secret out into the open - and suffer the backlash etc after being shot down in flames etc (if doesn’t work for you its not my fault anyway) so believe it or not what I did was smear some ‘Brasso’ onto glass surface. (Actual product is German ‘Sidol’ ) with my grubby little finger - nothing fancy or special, just smear it about for a thinish layer but not tooo thin. As to settings in Lightburn - I have a vector outline of subject and then ‘Edit’ tab - convert to bitmap, then in layer settings used ‘Atkinson’ . Different glasses may need slight tweaks with speed and power for your machine. Well, give it a try - let us all know what happened. ![]()

What does this do?

I’ve been doing glass with my 40W for a while now without any additions.

Ensure you use some steel wool to get the loose glass shards out of the engraving.

Nothing worse than getting a piece of glass in your finger… the doctor can’t see it …

Have fun

![]()

So much truth! BTDT. Still beats steel slivers in your eye. I’ve had some gnarly injuries and watching the doctor come at my eye with a Dremel tool still ranks right up there. Wear your safety specs, people!

Nice of you to share… but without PICTURES is it really true??

Yes it’s true… can’t see the shards, so no pictures ![]()

![]()

How about a picture of the finger (with or w/o) alongside the suspected shards … AND with the results on glass?

Perhaps you can tell us what are these products, Sidol, Grasso. From a chemical point of view. Your audience comes from around the world, so it is likely that neither product are available were we live…

And as said, a pic or more (of the product, of the results) are worth a thousand words.

Brasso is an old metal polish. They likely don’t disclose the ingredients but IIRC it has a distinct ammonia odor, is fairly thin yet creamy consistency, light tan in color, and dries slightly cakey/powdery. It’s a good mild/fine metal polish. In the same vein as Flitz but more watery and different color. In the US, I can still get it at the local hardware store but I haven’t bought any in many years.

Edit:

Ingredients : Water, Calcium Carbonate , Pumice, Tall Oil Acid, Isopropyl Alcohol, Oxalic Acid, Ammonium Hydroxide, Aluminum Magnesium Silicate, Aromatic Mineral Spirits.

The ammonia smell I recall may be from another old product called Tarn-x or maybe Nevr-Dull…

Edit2:

All I can find for Sidol contents is “soap” and Ammonium Oleate and has a pH around 9-10.

Hi all and Sundry… thanks for the comments… Sorry if a bit sketchy on details and lack of said photos. I will try to post in the next day or so (too busy doing glasses…) Here are some answers to items/comments raised.1) Jack Wilborn… Brasso is a brass metal polish… see Chris’s comments and pictures. Yes that Sidol picture is exactly what I have , it came from Germany. Ordinary Brasso is a little bit fluidy. Sidol more of a cream. I have a problem with methodology around (moderator edit) ‘steel wool’ and loose shards of glass. People have searched/experimented endlessly for a better method. I would not give a customer a lasered glass product with the results you describe. 2. James… I like the healthy scepticism… will try to get a picture for you soon… just smooth even finish - like sandblast etching… also it is Brasso not Grasso…Just try your local brass/copper/bronze metal polish - see what it does??

Managed to include this photo for you all. Nice smooth finish, no chipping or shards as I mentioned. Just 2 steps… 1) smear Sidol on glass, 2) Laser.

Wow, that does look good. Thanks for being a good sport, I was busting your chops ![]() .

.

Thanks for the idea. Ow I have another route to take with my machine. Keep up the good work, amigo.

IMHO, every technique I’ve used except an acid etch leaves shards… Some maybe smaller, but shards.

Beside acid, there is impact, such as sand blasting, and thermally using a laser.

The basic mechanism of engraving glass with a laser is to heat it until is exceeds the materials structural limits and shatters from expansion. I used to use a sand blaster with very fine sand on glass mugs/cups and also found I needed to run steel wool over them and remove the shards using this method.

How this can change the dynamics, using a coating, change how the material is actually damaged by the laser and resulting heat?

What is pretty common knowledge is that using an indirect method of engraving on glass results in lower resolution. This is how people do glass with visible light lasers, however the results are still shattering the glass.

There is no details in this engraving, do you have another one that shows how well the laser can do this?

Not an argument, just questions on how you can shatter glass without the shards?

![]()

Thanks James for the remarks, also Jack… I understand your point… the result leaves a smooth - non catch result. By non catch i mean you cant feel or pick up ‘shards’ with your fingernail or with steel wool or with a cloth wipe over. I dont think i have the gear to do a macro close up of the result. But being an engraver I do have a stereo microscope… so under magnification one can see what looks like bubbles at the surface - almost a shard ready to breal out but it is still attached. So your thoughts are mostly correct but this brasso coating seems to get control of the shard effect. Now as I said in original post results may be different for your machine. I have a generic Ruida 60 watt machine - so nothing fancy. Settings for this job was speed at 100mm / sec 35 % power Different glass brands seem to make no difference to result. I do think that if you had too much power you would get flaking/ shards. I dont have a glass on hand that has text/finer lines. Might do one after I get some work out the door and post. The resolution/detail would depend on the dither used. … If you want the best results (read 'more expensive and time consuming) go sandblast etch. I have not seen/done as good a result as sandblast etching with a mask. I offer and explain both methods to customers and they inevitably go with the cheaper option. Thanks again all.

This is why I started using steel wool. 5 years down the road this already broken piece, can come loose, it’s already started down the path… So I break them…

Of course, your choice…

I have a faux 50W China Blue from OMTech…

On glass I’m usually about at the bottom of where it will lase… Can’t lower it any more…

I have run into different kinds of glass, giving me different results… Used to use masks and bead blast things…

Have fun

![]()

Thanks, looking forward to try…

Are you using CO2 laser? Do you know if this will work on fiber laser?

As far as I know, 1064nM of a fiber, goes through glass and acrylic with no damage…

You’d have to use some type of indirect method if you want to use a fiber.

I use a co2 machine for glass.

![]()

Yes, I’ve marked glass with my fiber laser with good result by paint the glass first

I knocked the politics out of your post.

Telling folks that they have a problem may not be the most welcoming or constructive approach to sharing a hard won discovery.

Play nice.

Hi there John… No worries at all… Just my sense of humour I guess. But - Hey you posted that I have a problem? Maybe we should use the word ‘issue’ - more user friendly for all perhapes Cheers

Hi Sverrir, I use a Co2 - no experiance with Fibre sorry - Try it and see! Thanks

Just wanna pipe up here and say that brasso is volatile enough coming out of the bottle to warrant breathing protection, please don’t burn this in a laser. There’s a bunch of things in there that are very reactive and who knows what they turn into when burned. The one-time chemistry student in me is concerned. ![]()

On the topic of nice glass engraves, I found I got the best results when using light settings (low power and high speed) and doing two passes, offsetting the second by 90 degrees.