When running graphics under Atkinson, stucki, or Jaris mode is it using the min and max power settings or is it using a percentage on the max power setting for the grayscale. trying to get some fine tuning down between power settings and lighting as well as image adjustments.

in dither mode the laser is only on or off and the max power is choosen by you in the cut palette/layer

When you have an image scan operation, it only cares about Max power. The only use for minimum power is when the head will be changing speeds during the laser ‘on’ time, as vectors.

The Ruida computes the overscan, so the head will be running at the specified layers speed. No use for minimum power under these conditions.

I don’t know how it’s handled with a fill in a vector file, it seems to apply variable power. I set the minimum under those conditions.

This is used to do ‘3d’ engraving with a co2 and is a tough nut to crack. Here it will use max/min.

Many have had success with led lasers using grayscale.

Make sense?

![]()

Hi guys thanks!! Yes make pefect sense and answers other questions as well.

The 3D engravings is actually what i am playing with, they are going pretty good in all actuality with both the cO2 and diode laser. At present my biggest confusion has been when im switching back and forth between Co2 and diode remembering the settings has been the hard part ![]() Now i’m starting to use the library a little at least for my baseline.

Now i’m starting to use the library a little at least for my baseline.

Do you have a file with the configuration settings for each type?

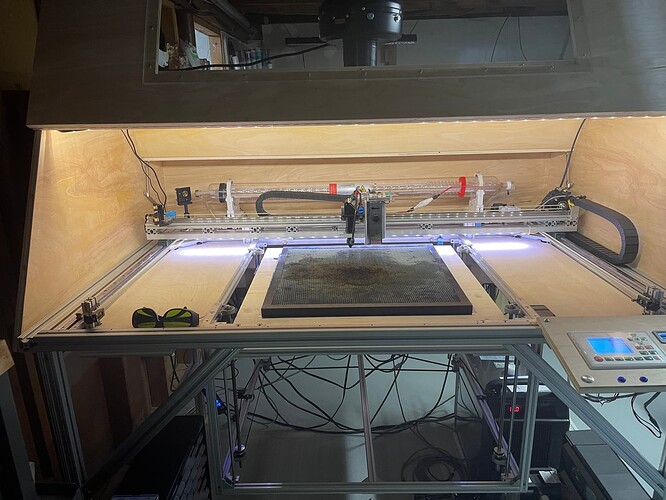

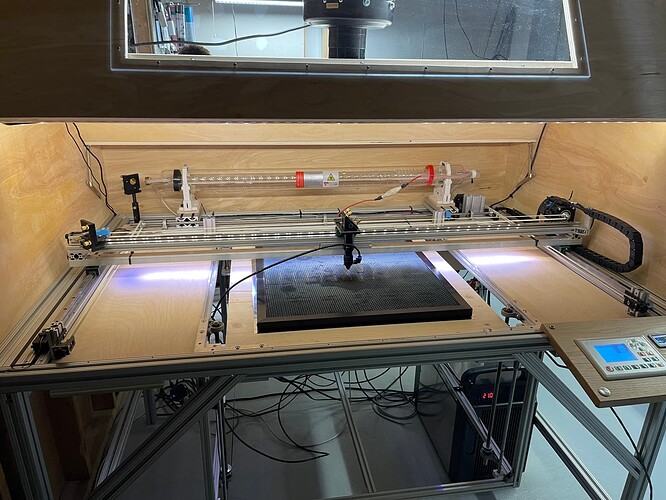

I’d like to see how you got the two lasers together on the machine…

![]()

Is that the .lbset File? is so here you go. Maybe you can take a look and offer up some recommendations at the same time LOL.

BachSystemsLaser Final.lbset (12.7 KB)

The only thing i still have to do manually is go to setting and turn on/off the tube and RF setting. Wish there was a key on the main screen to toggle this.

The whole setup actually came out very nice. designed and built the machine in 4 weeks when i got sick with covid lol.

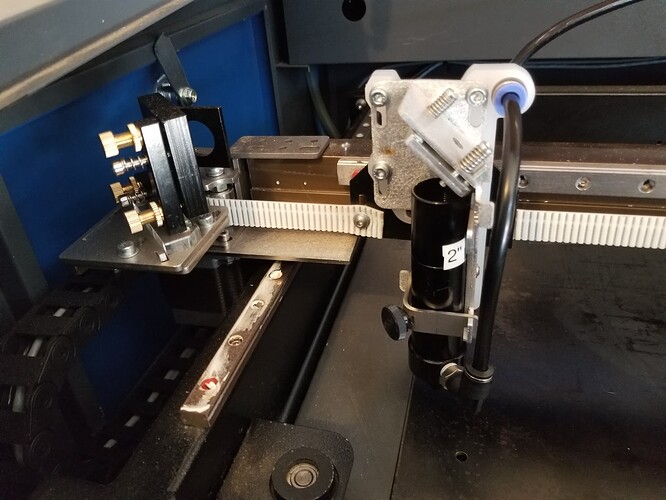

The good thing about the new atomstack is they have an on/off switch on their board. on my first go around i had installed a contactor that i could turn on/off because when using the C02 laser the diode would light up when moving place to place. Now with this setup i just switch it off.

Now i just wish there was a way to utilize the rotary without having to make it my Y axis.

Very nice and clean looking. Ever weighed the whole thing?

If you were sick when you built this, I’m awestruck…

If you get a handle on the 3d grayscale, bring it up. I drag it out and some of it looks like I’ve almost got it, but hasn’t really panned out yet.

Thanks for the photo…

![]()

@Bachman Based on the way it’s mounted I assume you keep the diode module on there all the time? Have you had to adjust down your engraving/cutting speeds on the CO2 side to account for the additional head weight?

well its funny because i ended up quarenteening cause one of my co-workers got sick so the first 14 days i felt great so i got all the 80/20 cutting done, tapped, drill, and started assembly. Then the 3rd week i started getting sick but was determined to get it done. spent many days in bed though lol. I figured the entire machine to weigh close to 300 lbs. Still making tweaks here and there, in high speed it still sways front to back cause i ran out of 80/20 to finish my cross braces. I did have the tube covered and protected but removed it for modifications.

this is a before and after between single head to both.

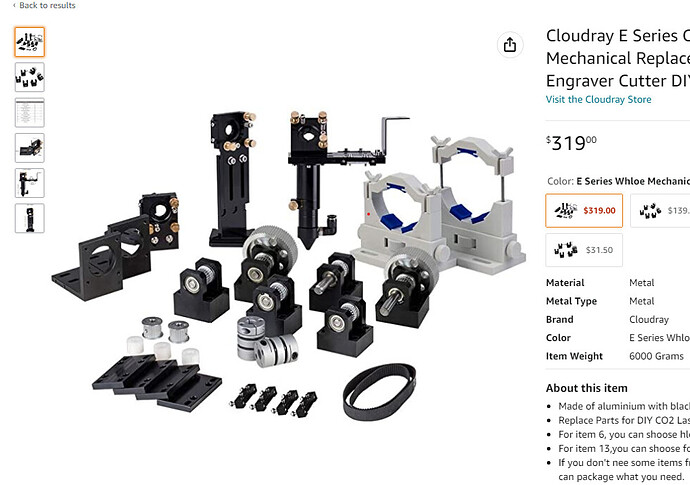

Not really the only thing that has been somewhat of an issue is the bearing tensioners i have used. Trying to find something more robust. 3D printer parts were everywhere online so started with the GT3 belts and setup. Have already wore out 3 sets of bearings on X axis. Trying to find a source for 15 or 20mm belts, guides, bearing etc… its all light as a feather. if i disconnect the belt i can literally blow on it and make it move!

Nice. What you got hiding back here?

[quote=“berainlb, post:12, topic:64103”]

Nice. What you got hiding back here?

[/quote]LMAO that the wifes cricket workshop. i have utilized my entire basement with toys now i need a bigger house!!!

That seems unusual. Do you know what’s causing the premature failures? I’m wondering if you have forces being applied in a direction that the bearing is not designed to handle… possibly from alignment or from bearing type not fitting application.

Oh wow. Thought it was some sort of CNC spindle or drill press maybe. Time for a new house or a shed at least.

my guess is because i used such narrow belt that i have to over tighten the belts a bit. it can move pretty fast when scanning back and forth. Im not afraid to slow it down but where some of the stuff is 8x11 or bigger the speed realy helps. Im looking for something like this but this is all i can find.

new house for sure, the 2 car garage is the workshop the cnc and laser are in the basement cause i ran out of room in the garage.

Ah… I get it now.

You’re likely undersized but the failure rate still seems high without something else going on. If I had to guess I would say that you may have some unaccounted axial load being applied. I suppose this could be from over tightening the belts if there was sufficient flex in the mounting plate. But those bearings should be pretty tough radially. I suppose the other issue could be from heat buildup due to increased friction from the extra belt tension and high speeds. Let us know how it goes when you upgrade… I’ve considered doing a DIY system for some time so building up a knowledge base.