Specific , okay .

No i did not download any settings from the original board because it have a fault that allow’s the Y axe to go outbound.

Still in dispute over that with the seller.

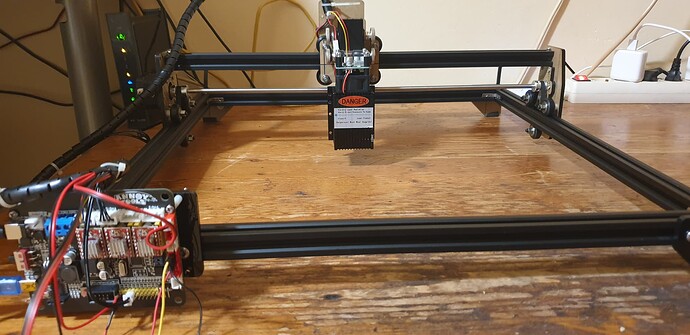

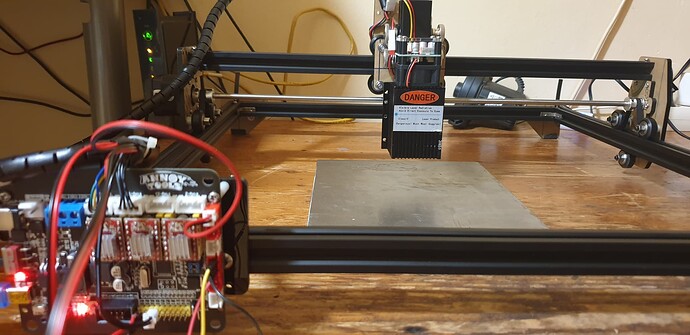

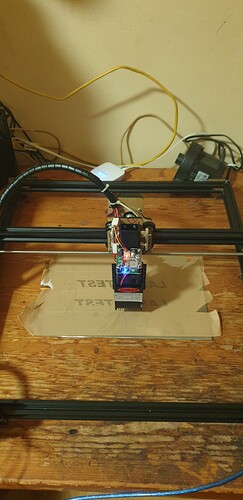

So i bought this grbl driverboard.

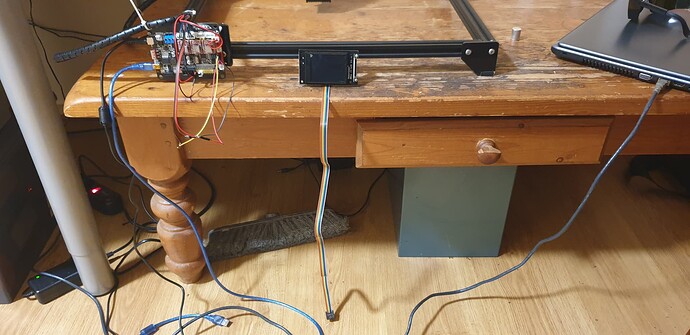

Yes i have the end stop’s installed and i measured with a multimeter if they work and they do.

I also measured the lead’s and connectors to and from the steppermotor’s also in good condition.

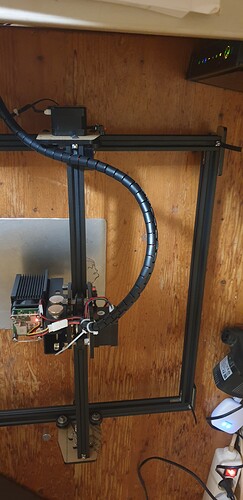

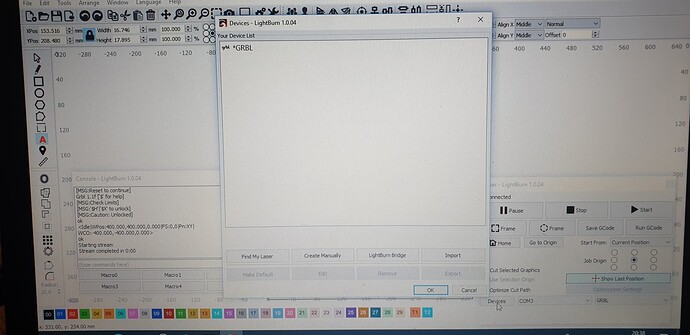

I used the help topic’s on lightburn website to get the machine working.

I learned that some grbl boards use negative position and so does my machine.

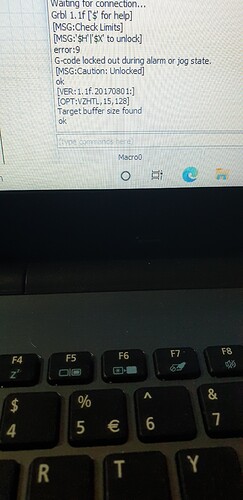

When turning on the power of the machine it does not automaticly home to X-0 Y-0

When i start using lightburn and setting up the machine it does home with the exeption that it stay’s there in place.

Even when i want to use the position tool in lightburn it stay’s at the end stop.

From here i started to try a little engraving.

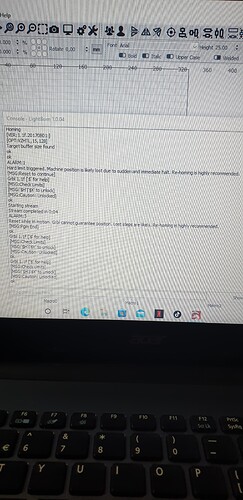

Everytime the machine did a hard stop with the message out of workfield .

But if i look at the program all the dimensions in the workfield looked good.

So try’d again smaller picture corner left up where my end stop is but i manually choose to put it a bit out of range from the end stop.

I only got a picture when i placed the picture in the lightburn program almost outside the workfield.

None of the settings provided by the beginner topics worked out for me , exept the one where you don’t use a endstop.

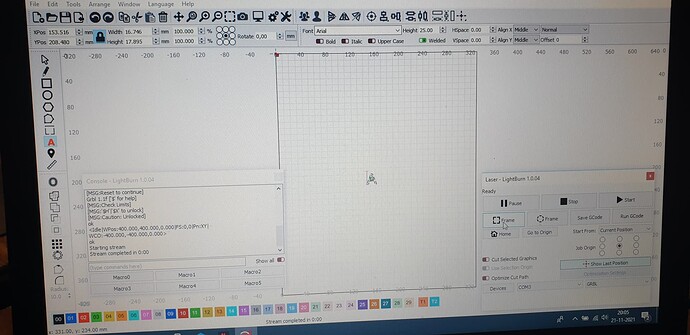

And i used the console code to put the workfield in the negative position.

Now it works , but it does not home ( to endstop) , and i need to set the laser position manually in order to engrave something.

So in this picture i just typed the A .

But you can see according to the program i have a lot more workspace .

My real workspace on the machine is now using A4 format just for the letter A.

But it say’s the format is in mm , my conclusion is it is in cm (centimeter) so this could be software related.

I am sorry this is gonna be a long explenation .

In simple words , i can’t get my machine to home and keep track of it’s workspace .

And i can’t use the workspace in the program to completely fill with an artwork or multiple design’s

Because i don’t have a good look on any dimensions besides the mm that are displayed in the program.

I know , it is a weird problem .

And i needed a week to setup the machine to work in one way or the other.

It works but not how it should.

I just want the workfield on the machine to be the same as in the lightburn program.

And if possible use the diode laser to point out the frame when i use the frame command in lightburn.

Either way i learned to work around some of these problems and gonna buy the program.

But i would like to see everything work correct.