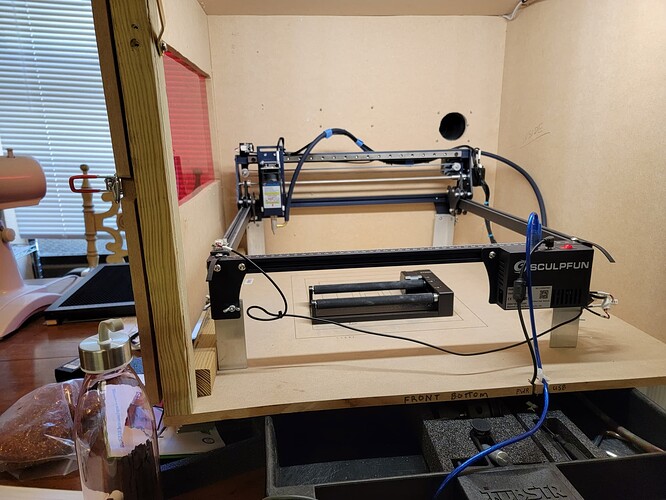

This is my pretty much completed project for a portable laser workstation. The wood id 1/2" MDF and 2"x2" lumber.

The box floor is 28" wide by 32" deep. Inside height is 18" floor to top. I should have gone with 26" wide because the side panels add an inch, making it a tight fin in a 30" door. The entire box is hinged to lift up giving access to the tool cart tray. The bottom of the cart holds future project materials.

The front and left sides are hinged and have 12"x24" viewing windows. A LED under counter light makes viewing possible. The bottom of the left side is an air gap for the exhaust The hole in the back is the 3" exhaust with an inline fan feeding a flex hose to a removable window panel.

The right side is removable for maintenance. The screw hole at the bottom center of the right panel is slotted so I can just sit it on the screw and install the others. Out of view is holes for the air pump power and tubing.

On the back of the rear panel is mounted a duct fan and power strip. The exhaust is nothing to brag about, but it does keep the stink out of the house.

In the center is the RA2 rotary, without the chuck. I was using it as a holder for marking water bottles (see lower left, and honeycomb behind that). Naturally, I needed leg extensions. I found nothing online i liked, so I made my own, 1.5"x1.5" aluminum angle was used. I made 3 sets, 2", 4", and 6" with the mounting holes 1/2" from the top (I was very precise drilling these). So I have 1.5", 3.5", and 5.5" risers. Wingnuts complete the attachment. It takes just a few minutes to add or subtract height.

Anti-Safety: As you can see, I removed the light guard from the nozzle. However, either the doors are closed or I have the safety goggles on. Not stupid here.

Pro-Safety: I have a couple of ABCK (actually marked ABCDK) water-based extinguishers mounted on the front of the cart legs. Even if I can’t put the fire out, it will snuff it enough to get the cart out of the house. You do remember I did say “portable”, right?

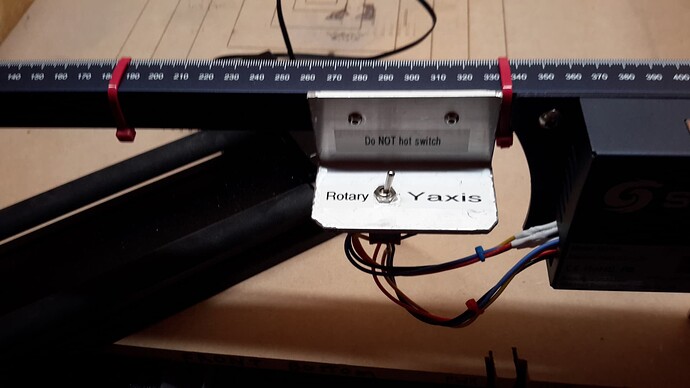

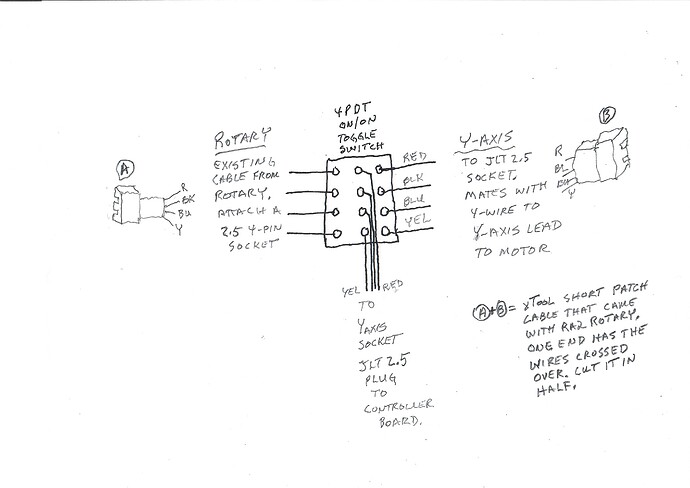

I still need to add a Yaxis-rotary switch, and possibly an air flow meter. I can park the rotary on the right side out of the way when not in use.

Overall, I am pleased with how this turned out. I wanted to use 3/4" MDF, but it was too heavy. This is Laser Box 2.0, as I had a previous one for the 3918 CNC/Laser setup. Now the CNC has its own cart, with a vortex dust collector.