I don’t know how different laser power supplies are labeled and wired.

i did this mod about a year ago so i am slow to remember what i did.

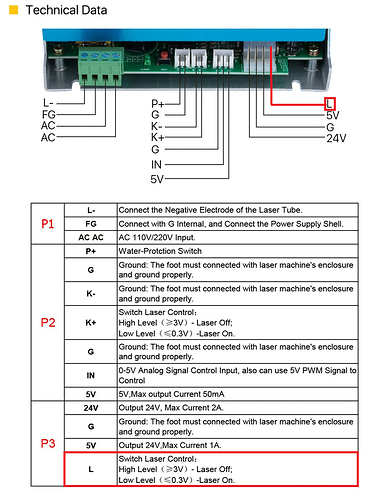

yes - pin2.3 (Fan Fet) of my smoothie pulls-down L terminal of my laser power supply like so:

I guess you can chose to use pins 2.4, 2.5, or 2.7 the same way. i chose 2.3 as the fet is “quicker/faster” than the others and i thought it wont hurt thinking fast engraving and such but frankly - all are much faster than required.

Correct.

Not sure what you mean. fire is part of the panel (digital panel) and triggered manually if required. not connected to SKR.

Please use this information with the utmost care.

Cheers.