Hello (again),

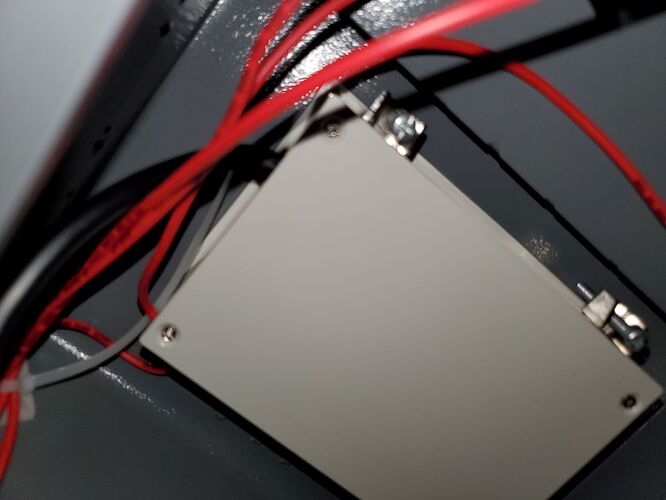

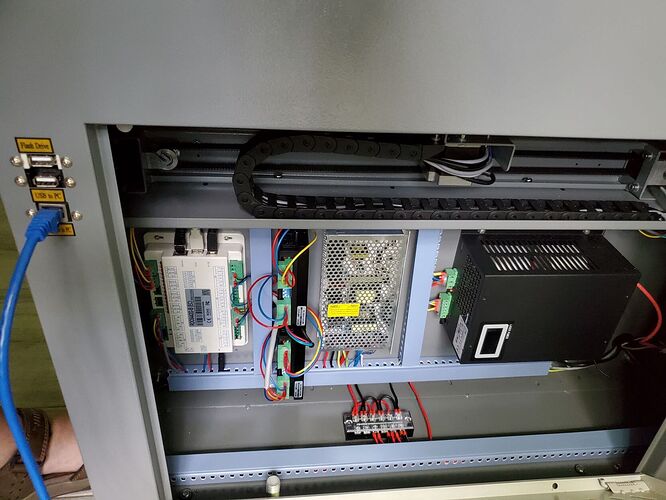

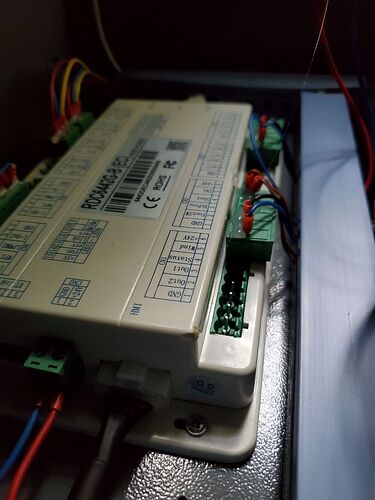

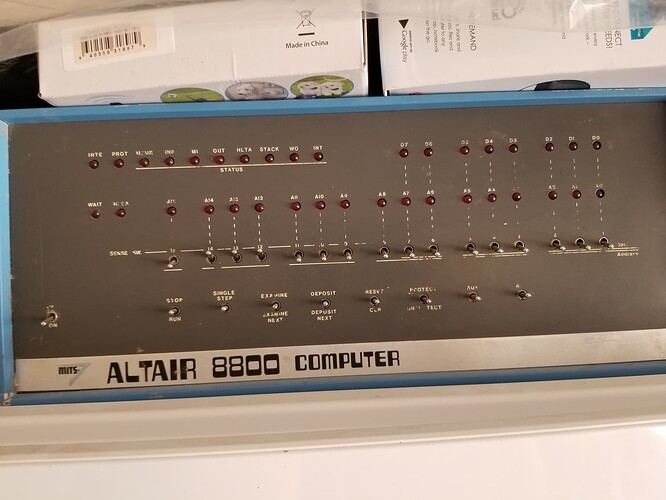

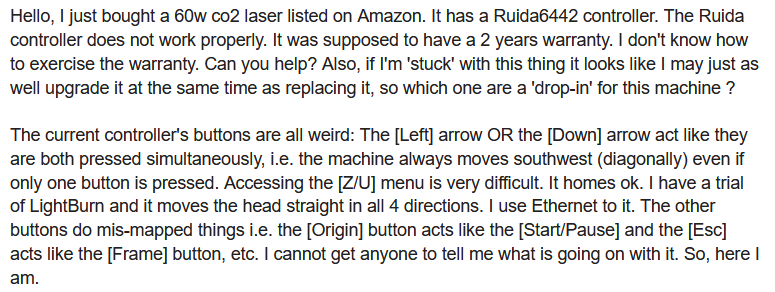

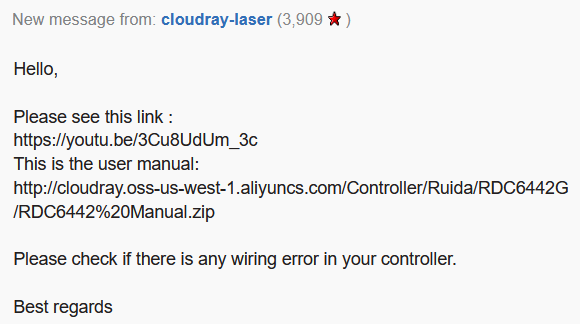

I think figured out how to embed pics, so , sorry if I’m too profuse, here is what I’ve got. The console_top pic looks like most Ruida6442 consoles. No surprises there. The console_underside pic shows the lacking cable plug, but otherwise looks straightforward enough although I had to hold my cellphone camera to see it (I’m 70 and my body doesn’t work very well). The right_side_cab pic is just that. I did not remove any of those grey trough covers. Finally, the Ruida_HMI_plug pic (which also only my cam could see)(although I could feel it with my fingers) is well plugged in. I even was able to ‘wiggle it a tad’. In doing so nothing changed at the console.

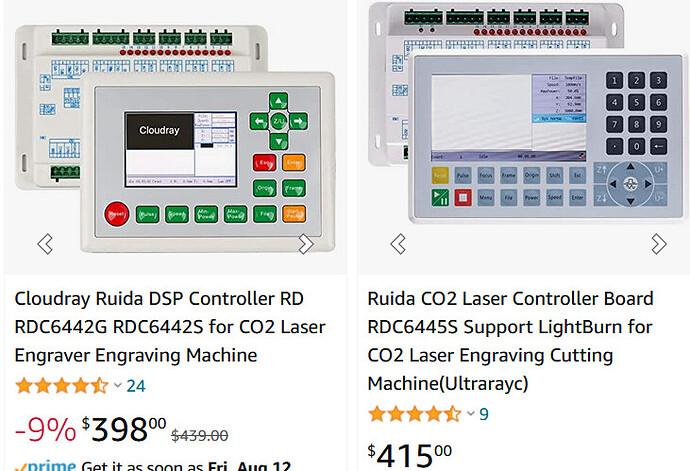

I suppose that IF the seller will send me anything under warranty THEN I may get into it all. I am knowledgeable enough to swap out components, it’s just that I seem to have a stubborn streak about buying a brand new machine and having so much trouble with it right off the bat (hence my interest in the warranty issue). If nothing else, this whole episode shows both my ignorance of buying these kinds of machines and/or of the seller or source. And that was AFTER I did a mountain of what I thought was due diligence in studying various forums and videos and online sellers (I live in a remote area with no nearby sellers, not even OMTech dealers).

Alas I am very frustrated, perhaps I’m ranting, or at least raving. I’m certainly aware that forum members have been trying to help me. Perhaps I overestimated having a hobby in my retirement. I haven’t even had a chance to get into some of those more technical issues that many laser users are having. I guess I wrongly though it would be more straight forward.

I’ll wait and see what the seller has to say, especially as to the warranty. I sent them a link to a video of what is happening (either arrow button sending the head SW {not straight left or down} and other buttons mismapped. Perhaps I’m supposed to wait on a slow boat from… …meanwhile… …tic,tic,tic…

If I can make this link thing work here it is:

to my video of what is happening (no dinging sounds, overdubbed)

here is a link to the original (no overdubbing but listen closely to the console dinging):

original (but larger file)

BTW I did find a PDF of a Ruida manual albeit different from the one that you attached (but fairly close)(perhaps just a revision but I don’t know for sure)(I see the “v1.3” in the filename)(but I just downloaded the other from the Ruida website last week). I noticed one has a copyright dated 2016 and the other has none that I found. But then one has 60 pages and the other has 51 pages. So then it’s another mystery to me as to what was the 9 page difference ? Oh well, one problem at a time.

Thanks for everyones help,

Bronco