Rick

October 19, 2021, 10:07pm

9

I am seeing very confusing things on your control HMI panel that I do not see in the LightBurn file. Looks like some lead-in is being applied on some shapes that are not present in the posted file.

I also see that your laser firing is not fast enough to keep up with your movement. Look at the following for assistance with that: Scanning Offset Adjustment - LightBurn Software Documentation

And I would also look into this,

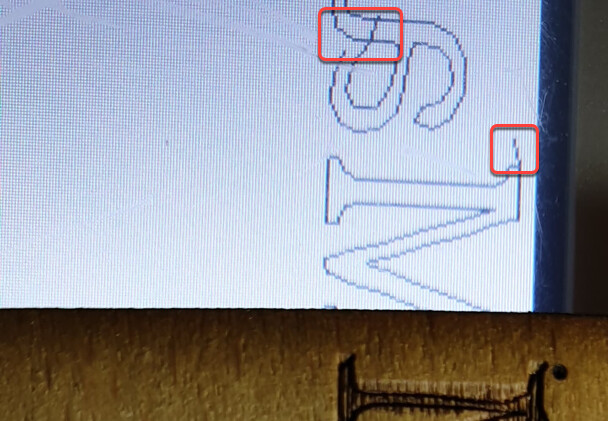

This is an example of a fill followed by a cut around the letter A:

[image]

The fill is slanted, but the cut appears to be correct.

If you have engraving that is slanting to one side, but cuts appear correctly, you likely have your motor pulse step polarity set incorrectly. On Ruida controllers, there’s a setting called ‘PWM Rising Edge Valid’ that you can change for each axis that tells the controller whether the rising edge or falling edge of a step pulse is what the motor driver is lookin…

![]()