I have a new xTool D1 Pro with the optional 1064nm infrared laser. I need it for laser engraving (technically, laser foaming) on ABS plastic. The xTool Creative Space software worked pretty well on my very first attempt. Sadly, the Creative Space software text function is not Unicode compliant which I need for this application, so I’m trying out LightBurn. So far, LightBurn has been a total bust with the 1064nm infrared laser. Not sure if this is a LightBurn bug or user error.

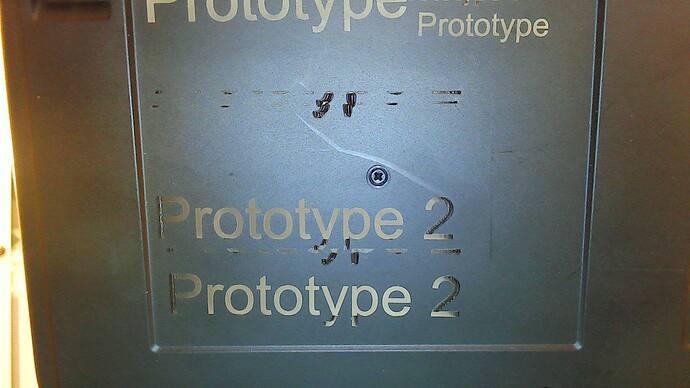

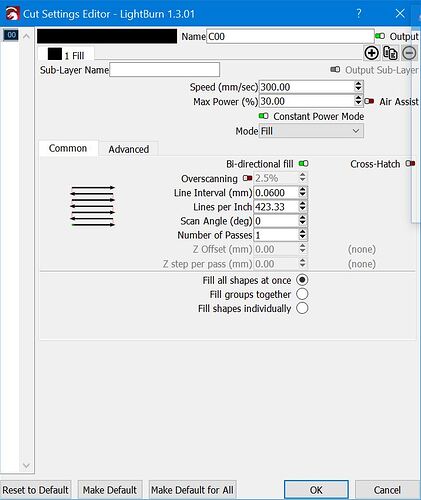

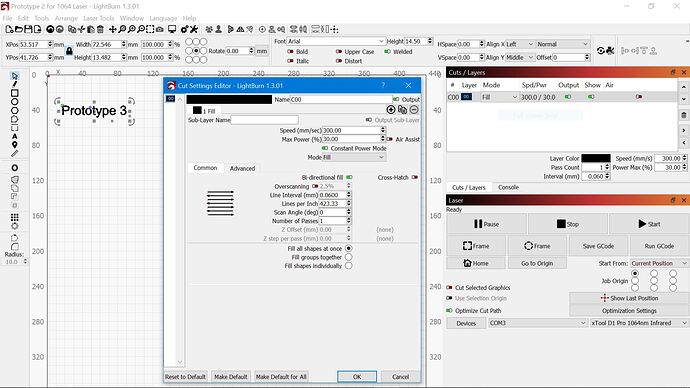

For my first attempt with LightBurn, I used the same power and speed settings that had worked with my single experiment using Creative Space. I had to stop the LightBurn test almost immediately because I was afraid I would set the ABS plastic on fire. The laser was melting the plastic, not foaming it. I made several attempts, increasing speed and/or reducing power, but getting basically the same result every time. I started with 60% power at 100mm speed and ended with 30% power at 300mm speed. I also increased the line interval from 0.03mm (where I think it should be set based on the 0.03 spot size of the xTool infrared laser) to 0.06mm. As I said, the result was pretty much the same for each test. See photo.

No matter what speed or power settings I used, the downstroke of the capital P, the descenders on the lowercase y and p, and a goodly portion of the number 2 were all melted instead of laser foamed.

Note that I successfully used LightBurn to engrave a “Laser in Use” caution sign on birch plywood with the 455nm laser using power and speed settings first tried with the Creative Space software. That sign came out pretty much as expected. (I tried experimenting with wood first, figuring that accidentally setting wood on fire would be far less dangerous than setting ABS plastic on fire.)

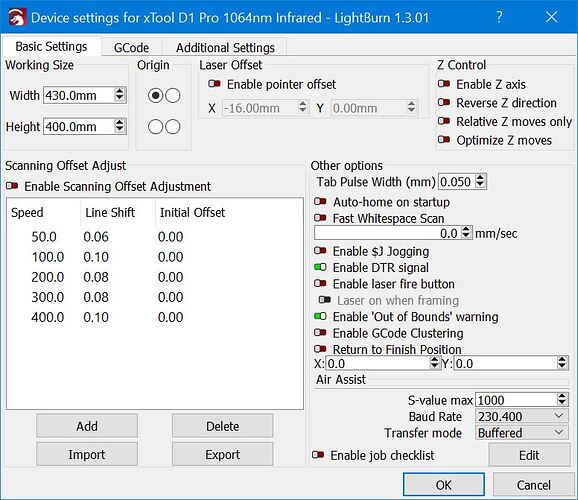

Also note that I have two definitions for the D1 Pro machine in LightBurn - one for the 455nm laser and one for the 1024nm laser. These definitions were set up using the lbdev file for the D1 Pro available from xTool, and then modifying those defaults for the 1064nm laser as recommended by xTool.

What’s going on here? User error or bug? Given that the power/speed settings for the 455nm laser wood sign worked about the same with both software packages, but the 1064nm laser power/speed settings did not, I’m going for bug, but I’d be happy to be proven wrong.

How happy? REALLY HAPPY. I’m leaving for a conference on Thursday and need to have prototypes ready to take with me. FAST HELP APPRECIATED.