I am trying to create secondary language letters on existing keyboards in a low production environment using an xTool D1 Pro, their infrared laser module, and LightBurn. I’m getting reliably inconsistent results, even after xTool sent me a replacement infrared laser module. Is this a problem with LightBurn that I might be able to correct with different settings? Is this a problem with the D1 Pro? Or am I simply asking too much of a laser in this class and price range? Note that this is a continuation of a thread I started (and abandoned) in January called Incorrect operation with D1 Pro and Infrared Laser

Background: What I am doing is formally known as laser foaming. The laser heats the ABS plastic keycaps just enough to create small gas micro-bubbles under the surface via liquid vaporization without melting or otherwise removing any of the material. The micro-bubbles diffuse the light differently than the surrounding material such that a light mark is made on dark ABS (and dark marks are created on light-colored ABS). Too little laser energy and nothing happens. Too much laser energy results in melting of the plastic and the nice contrasty light marks become darker and look somewhat burned. Way too much laser energy results in engraving of the substrate, much like we do with wood, and is a big no-no as it releases nasty poisonous chemicals.

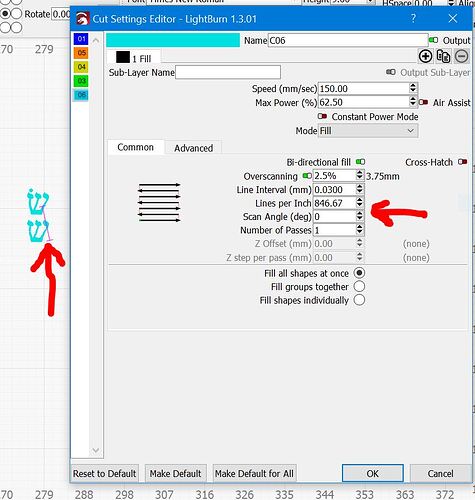

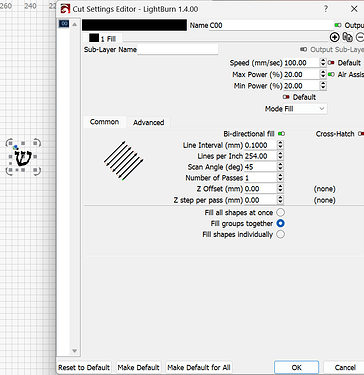

Here is a nice looking set of test characters. The actual setting used for production is the one used to create the lower left character.

The problem I am having is that I can create a nice-looking mark for a single character in testing, but when I use the same settings to mark an entire keyboard, the identical settings fail. Thinking that overscan settings might be an issue, I doubled the default overscan setting recommended by xTool, but that didn’t help. Indeed, I can create two high-quality characters spaced about a key-width apart, but again, when creating an entire row of characters, failure ensues. Typically the failure is that there is too much laser energy resulting in dark, faded-looking marks. That is the exact opposite of what one would expect if the overscan was too short.

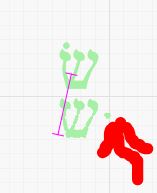

Here is the same letter located on the proper key. The entire row of letters (A through L) was produced at once. The entire row looks like this. Light at the edges, too dark dark and starting to melt in the middle.

I’m also seeing characters that are faded at the right and left edges when testing with just a two-character pair, as if the laser were moving too fast or not giving enough energy at the beginning and end of the scan line. Again, that is the opposite of what one would expect if the overscan setting was too low. In the above photo, 4 and 5 were burned as a pair, 6 and 7 were burned as a pair, as well as 8 and 9 were burned as a pair. I thought the settings for 4-and-5 were too dark based on the fact that the circle outline of dots were correct but the two large dots at the bottom of the character (on key 5) starting to melt. I dialed it back just a little bit for the 6-and-7 burn. It might seem as if the keyboard was moved during the burn, but what is actually happening is that the dots are not being fully formed. The center area of the dots forming the circle are missing and the bottom dots are mis-formed. For burn 8-and-9 the same settings as 5-and-6 were used. The circle of dots has the same problem with not enough laser energy, but the bottom bar and dot on the 8 key got too much laser energy.

The 9 key looked just fine and is not pictured. Go figure.

Finally, here is a sample of characters that are absolutely inconsistent throughout. Proper laser foaming with a bright contrasty mark in some areas, dark and melted in others.

FWIW, the area around the D1 Pro is well controlled temperature wise. Further, all of these burns were made within a few minutes of each other, meaning even if the air temperature changed a little bit, the temperature of the material would barely have changed at all.

Help! Is there no way to get a consistent output from LightBurn and the D1 Pro?