I certainly hope you do. Thank you. You went above and beyond.

Not really, I just did not want to let a machine outsmart me. You are welcome!

That statment only tells me that the problem lies in the Lightburn program. Most all software allows reporting in mm or in. That is just a conversion from native units to either decimal or metric. GRBL has proved that it can handle that. I run 8 machines with several different senders and operating systems. I have an old faithful board coming that will answer several of my questions.

The results are in. Changed $13 to 0. Left Lightburn software set to inches/min.

All is reporting correctly. Proves to me where the problem is.

LightBurn handles unit conversion fine. It’s natively metric but shows standard units on display. When sending g-code for a job specced in inches it will actually send inch units to the controller along with G21.

However, it expects reporting of all values from the controller in metric. Whether or not this is done to reduce the number of conversion steps or for convenience I do not know.

Position reporting is done in one of 3 ways:

Software reports where it thinks the machine should be.

Controller reports to the software where it thinks the machine should be.

Resolver tells the controller, which tells the software, where the machine really is.

Do you see the weakness of the first two methods? I do not know what is different in your situation, but I do know users would never let Lightburn get away with the errors you are describing. Are you positive about the $10 settings on those other GRBL boards?

??? $10 or $13

Just tested $10. Changed from machine to workspace and back resetting the firmware each time and I get the same readout on the screen DRO. Is it supposed to change?

Can I blame this on a typo? $13 is correct.

I said I would try to find where I got my steps figure. Here it is .

Here, we are interested in the “Steps/mm” settings.

$100=314.961 (x, step/mm)

$101=314.961 (y, step/mm)

$102=78.740 (z, step/mm)

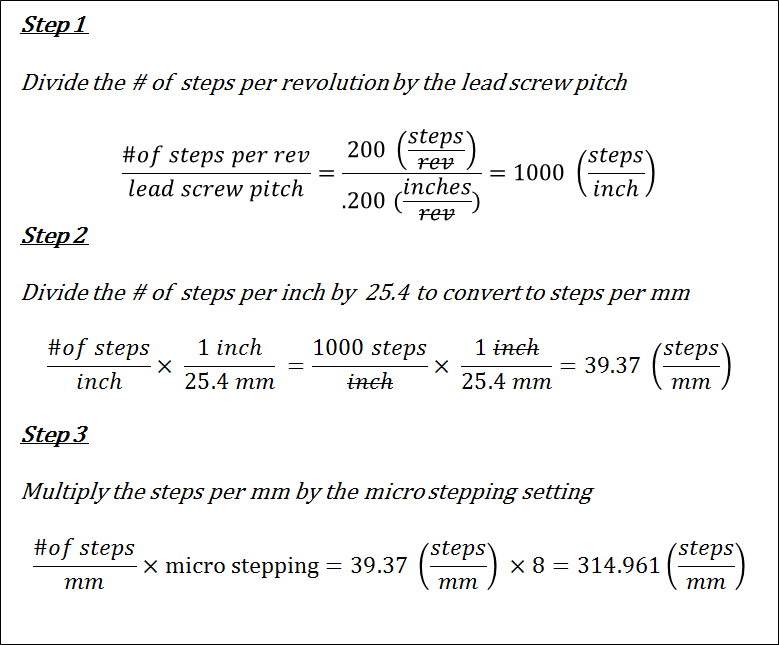

Note these were not the default settings on my system. How did I get 314.961? Good question. All it takes is some quick math and a few pieces of information.

Lead Screw Pitch = .200 inches (inches per revolution)

Stepper Motor # of Steps per Revolution = 200 (steps/revolution)

Micro Stepping Setting = 8X

I am using .200 inch pitch lead screws, my stepper motors are 200 steps per revolution and my stepper motor controller is set to 8X micro stepping for the x & y axis.

Calculating the “step/mm” Value

Lets break it down one step at a time.

Example calculations demonstrating how to find the step/mm value for your grbl settings

Example calculations demonstrating how to find the step/mm value

After a few quick calculations you have the values you need. Update the GRBL settings by typing the following into the command line.

$100 = 314.961

This will set the X axis steps per mm. Repeat the process for the Y and Z axis using $101 and $102 respectively.

Note the Z axis setting is different because I am running a lower micro stepping count of 2x to get a little more power to lift the head of the mill.

Final Thoughts

Remember, these are just initial values to get you int the ball park. We will need to use a dial indicator and tweak the values to get the most accurate motion. More on that in the future.

Are you building a CNC mill? Are thinking about building one? Are you simply fascinated by CNC machines like me? Tell us what you want to make in the comments below.

Thanks for reading. Until next time…

A lot of this stuff is not as simple as some folks think. Dan

No problem. At 75 you should see my typos.

It gets worse as you get older. I am 77 so I am a voice of authority!

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.