Hello. I just purchased a laser along with Lightburn. I told the laser distributor what i was trying to accomplish when purchasing but im concerned after a great deal of money spent i still need to have files made in some CAD software. Trying to take specs of baseplate on paper and enter them into computer for cutting.

Welcome. Show us what you have, and explain exactly what you want to accomplish, and we may be able to offer some suggestions.

Thank you for replying. My background is with traditional tools, carpentry, Engine development. I am trying to make the leap to machines doing work for me. I purchased a Light object “Solo” upgraded to 60w. The controller is Trocen AWC7813. Computer is HP with an old I7, 16 gig of ram, The PC is dedicated to laser with fresh install of everything on New 2.5 hard drive.

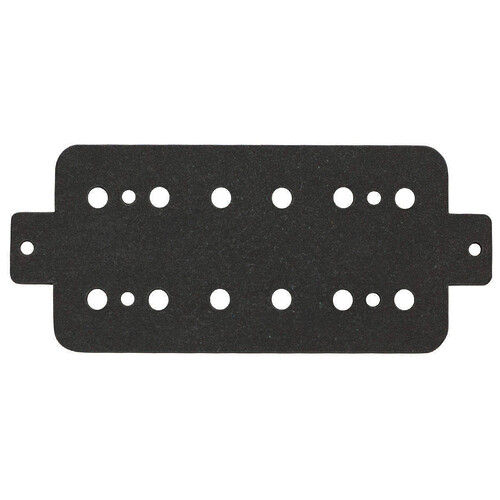

This machine / software was purchased with zero previous experience. I told the light Object guys i needed to cut Vulcanex in two thicknesses, but could not find info on cutting this material. all i knew from the two videos i could find is that a Ebay k40 was not going to cut it literally. The two thicknesses are .062 and .092 to build custom and factory guitar pickups. I took in a Gibson sized baseplate cut from fiber and told them i needed to reproduce what was in my hand.

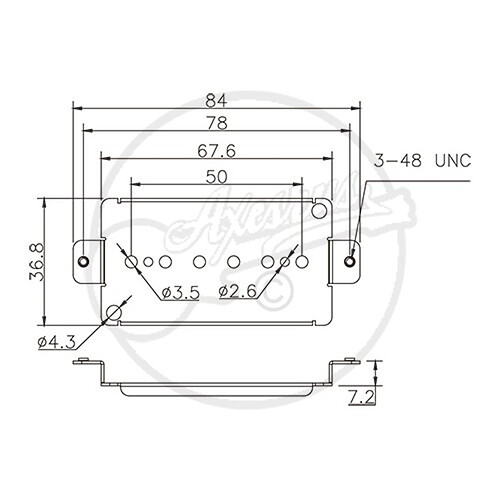

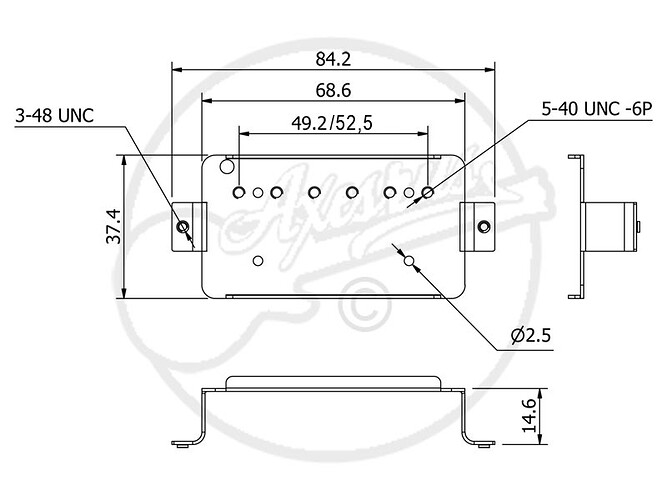

The specs are blueprint/pics on computer , not generated on some computer program, it’s just the dimensions and hole size info. I tried looking at File Sellers but no luck. closest thing was files for guitar pics. Today for the first time i combed over lightburn and do not see how to get what is on paper to cutting in laser. There are many baseplates. Gibson humbucker / P.A.F. 49mm, 50mm 53mm, Fender Stratocaster, telecaster, Jazzmaster , and many more plus custom designs.

Thank you for any help

here is a link to a diagram of flatwork.

Single Coil Pickup Fibre Boards

Vulcanex ® Vulcanized Fibre & Fishpaper - Oliner Fibre This is the material. the 60w cuts the thicknesses i use quickly in one pass.

A basic idea of how many i need to have files for plus the ones i have designed.

If the camera could do what i need that would be impressive. I do not see how it would be accurate enough. Im guessing i need to have these items created in a CAD program then import to lightburn for cutting? Maybe freeCAD… I do not have Solidworks or Confusion 360

What type of tolerance are you working with your pickup designs? That will determine what tools/methods would work best for you.

In case there’s still any confusion, LightBurn absolutely does not do any sort of parametric modeling like what you’d imagine from a CAD program. It’s perfectly capable of doing some complex designs at extreme accuracy but it’s not trying to be a drawing tool and it’s not trying to be a CAD tool. It is, however, extremely versatile and flexible and works well with other tools.

It sounds like your blueprint/pics might have the necessary information to build the designs. From the examples of the flatwork that you sent those can likely be designed directly in LightBurn without too much trouble. Where LightBurn isn’t going to be as flexible vs a CAD program is where you might have to make a lot of slight variations to the same basic design. In LightBurn you’d have to basically redraw or move things around manually vs a parameter change in CAD.

If your tolerances are looser you could likely get away with taking a scan of the flatwork and tracing the scan in LightBurn. That would likely get you better results than from the overhead camera.

Are you willing to share one of your blueprints? Someone can give you an idea of relative effort in building it out.

Thanks, i have all the parts in hand. I found a guy on Fiverr to do the cad drawing for me for a very fair price. Thanks for the help.

Yes Lightburn is at heart a very powerful package capable of designing. Not the easiest to get to grips with but really quite powerful once you get used to it.

It might be possible to import the picture of the design into Lightburn and the use Trace to convert it to a vector.

Yes light burn can make many shapes, look at some of the posts on here. I create many files from scratch using just lightburn. Check out the tutorials before slating a credible piece of software.

… you are fast on the trigger. I have a small business with my laser and produce everything from lamps to Christmas decorations, prototypes and tools … for that I use LightBurn.

When my camera on the laser machine is perfectly adjusted, I have a repetition accuracy of less than 0.5mm on items that are 250x250mm, when I have a proper drawing or blueprint, I scan and trace it for production purposes. But, of course, I have spent some time getting to know the program.

I hope you find a better program or other program that suits your needs, but I doubt that a CAD program can control your laser in the same way that LightBurn can.

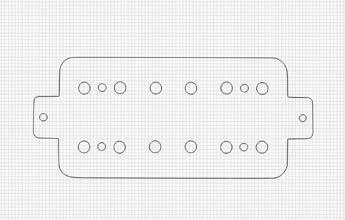

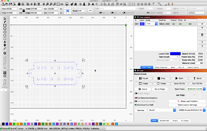

Pictured is a scan from one of the drawings here, but alternatively it will take me under 7 min. to draw this topic in LightBurn.

This is worth review: https://lightburnsoftware.github.io/NewDocs/CreationTools.html

I am not sure where or how you got these impressions, but they are not accurate. ![]()

You may want to review our documentation, at least the Simple Project section, to better understand LightBurn and how to get around. The shapes for the pickups are extremely simple and as @bernd.dk identifies, with a little time and practice, one can knock out a design in mere minutes.

Here I’ll show you. I went to the site you linked, did a quick screen capture and pasted that directly into LightBurn. Then used the Trace Image to duplicate this design, producing the vector art in under 30 seconds.

(click to enlarge pictures)

Of course, if you are more comfortable designing in a different tool or paying someone to do this work for you, that’s fine. Just save that work in one of the many file formats we support and import that directly into LightBurn.

We have many types of industries and individuals using LightBurn for simple fun to full manufacturing production. What you are wanting to do should be very simple. One of the most creative luthiers I know has had great success reproducing hard to find or no longer available parts, cutting inlays of all kinds, producing one of a kind masterpieces that are of museum quality (Keith Urban’s CMA induction into hall of fame guitar as an example).

We have folks from gasket manufactures and medical supply, Schools to DIYer’s making engraves on party food, Industrial parts suppliers marking products with sequential part / serial numbering, to glassblowers signing their works. And the list grows…

LightBurn provides a lot of options. What you are wanting to accomplish should be a snap. New tools take some time to learn, let alone master. We are here to assist, if you decide to continue with LightBurn. ![]()

Your other option is LaserCAD for the Trocen controller, which trust me you would be even less pleased with.

I think this is a situation where you asked for something, LightObject provided you with the best option that can design AND control the laser (the only other option aside from LaserCAD) but did not provide a proper explanation with how to get to your end result. As a former manufacturing engineer that has ran into this many, many times I understand your frustration, but what you are stating here simply isn’t true. LightBurn can absolutely reproduce those designs but it will take some work on your part to draw them.

I would pay someone to make the files. I am not a Computer Science, Robotics, Aerospace engineer as J Michael mentioned. I am a certified Air Flow research and development Engineer and Certified race engine Balance and blueprint tech. If someone wants to make some money making these 30 second files i would gladly pay for them. This is the one thing i am unable to do myself. There are many baseplates needed both factory and my own custom designs.

LightBurn staff is here and willing to assist and direct you to how you can do what we have shown, whenever you might be interested.

I might suggest you create a new post, in the general section, asking for a contract designer / CAD person to help you generate these files to your exact specifications. This will increase the potential responses, vs at the bottom of this thread.

I am going to say something pretty brutal…

It seems to me you have given up before starting.

You are obviously a super smart guy to be working in the field you are… and you can absolutely learn lightburn if you want to… and in doing so, you will be able to import those blueprints, and make adjustments really quickly…

You just have to commit, and give it a go.

Maybe I’m missing something. one site said this part costs $1.80. is the cost of the equipment justified?