I’ve recently acquired a rebranded LTT ils 3NM CO2 laser cutter/engraver (2006/7 vintage ) complete with a dedicated extraction filter/compressor for air assist.

This is my first experience with a machine of this type.

I have a dedicated PC running Win 10 connected to the laser machine and it can communicate through the parallel port.

Can I use lightburn to operate this machine.?

It’s alway nice if you add a link to your machine… otherwise we have to search, then guess which one you have…

Is this it? You have to remove the .txt extension.

ltt-nm.pdf.txt (1.3 MB)

If Lightburn will connect and move it via your computer, it should work…

If the above manual is for your machine, it appears to use it’s own proprietary software.

There is no parallel port on any of the current models. Usb or Ethernet seems to be the choices.

Good luck

![]()

Thank you Jack for your kind response and so quickly too.

It’s a rebranded Laser Tools and Technic machine model ils (intelligent laser system) model 3NM or model 111NM (depending on how “three” is translated).

It is an older machine manufactured 2006 and originally purchased in early 2007 by a school.

I have a link for the manual: https://www.lttcorp.com/upload/2020_09_032/20200903152414nzqrp8CLt2.pdf

It’s a fairly hefty machine weighing in at around 200KG

being an older machine it connects to the PC via parallel port (I’ve managed to install a card in the PC to link to the laser) and communication is established between the two machines evidenced by the laser receiving a file to print from the PC.

However so far I have failed to get the machine to execute any file sent to it.

I have no idea what programme was used to prepare the art work for the machine but I do have the printer driver from the manufacturer installed.

On pressing RUN it comes up with an error message bad command in work file

offset=0x 0000000D cmd = 0x1b 0x61

This means nothing to me other than there is an offset issue.

i was hoping that lightburn might provide a way of working around this issue and therefore I might be able to use the machine.

It seems a shame to scrap it if it can be tweaked to make it operative again.

I doubt you’ll get Lightburn to work with it’s current controller. Even if you can get the controllers input to look like a usb, I doubt it will talk.

Maybe you can post a photo of the controller itself…?

Absolutely. If you can identify the motor drivers and motors, you may be able to purchase a controller that Lightburn will support.

How handy with diy are you?

![]()

"Any Windows graphics such as image, logo or text, can

be transferred by the laser on to wood, acrylic, leather, stone, etc. "

“The printer driver of ILS-III-NM must be installed under the Microsoft Windows

environment. A clear understanding of MS Windows operation is essential for the

operation of the laser system. The installation of this driver is identical to other Windows printer driver such as HP printer or EPSON Printer.”

It appears you would print the graphics direct to the printer, via the parallel port. The part in bold is going to be the problem. If I remember right, HPGL was popular back then.

Is this a desktop machine? I have been trying to find a USB to Parallel Port interface for a while. I have found nothing available that has full handshaking capability.

I will try to identify the controller board type though it means a bit of effort to move the machine in a small cramped garage. As for my diy skills I would say I’m fairly confident of my abilities. I’ve made it my goal to learn as many skills as I can. Plumbing, electrics single & 3 phase. Plastering, welding, woodwork, electronics bricklaying and cookery. I think I can cope with most challenges. My computer knowledge is tending to be a little outdated these days but I do try to catch up.

The installation of the printer driver I think I’ve mostly overcome. I installed a pci e card to parallel port in the desktop machine and just for fun I also installed a “standard” pci to parallel port card. So I now have 2 functional parallel ports on that PC at LPT3 and LPT2 respectively. LPT1 port address seemed to be reserved for the mobo even though there is no header available!

Are you looking for a parallel port for a desktop machine? If so this is what I bought from Amazon It was a very easy install since it came with the drivers on a disc.

https://www.amazon.co.uk/ASHATA-Express-Parallel-Converter-Controller-default/dp/B07VHCQ9VN/ref=sr_1_3_pp?crid=1KR6IDEXUYAMY&dib=eyJ2IjoiMSJ9.687ED9MrMyKuOE4oqGQwDTG_4LAL318T8OCN3q9lKV8g_Nt-ZzGb8Hwq0Xb33MwOKO_j3qkfPL3dgT6OEIatuxPJnsSRpDlezqLQ4kzXiFt96yQC-iuFc4ruosCYluotsihTbUWeLZl3Sr-9b1C9Jx-RqticSFNAQ6wus3E9fsL7omkjGnM8e3MnoNQAk-AexP0TifZGgCrTqyRNcAq2kxl8K-eHx_qEsDd4tWJFsZk.1IU4uxI9Y4BscUaX6Yce3XB_V4V7ZOrIn5GEOXh1rHY&dib_tag=se&keywords=pcie+parallel+port+card&qid=1705402779&sprefix=pcie+parallel+card%2Caps%2C224&sr=8-3

The other standard card had no drivers, no tech support, and no information. Installation took about 4 days and around 50 different drivers before I stumbled upon the one that worked. It did however come wrapped in bubblewrap to protect it from the postal service!

- List item

Thanks John but I’m not in the market for another laser and I’m in UK so import and shipping costs would be prohibitive anyway.

No, all my desktop machines are collecting dust. they got retired in the XP era.

Thanks!

Hello Jack

Thanks for investing your time on this.

Here’s what I know so far:

Presto ILS 3, Top solutions ILS 3NM,Pinnacle Accuris ILS3 NM and my machine are all rebadged/clones from Laser Tools and Technics Taiwan.

Mine has a FABIA FB2612 ver.1.5 LAS4 Mainboard with what appears to be a “daughter” board with RS232 ports, Ethernet controller chip realtek RTL8100C and there is USB 2.0 chip somewhere on the board.

There’s a Motion control board upon which sit 2 x atmega 8515 chips (likely 2 more covered by another expansion board).

I have photos of the boards if they are of any use. BUT I don’t know how to attach them. This is the frist forum I’ve ever joined.

I’ve never heard of one of these, which really doesn’t cover much…

It seems like some of the original technology, likely the same time frame…

You will have to weigh in on how much you want to invest. One of the most difficult and costly items is the actual frame, case and internal workings. These are generally pretty expensive in itself and it has to be 3d square, so to speak.

I don’t know how diy you are, but it may be less costly and quicker to just replace the electronics. If you can identify and keep the motors that would help … Motor drivers are about $20 US each, a control board and maybe a new power supply. I’d think the lps (laser power supply) would still use the same pair of signals…

The Lightburn people are much more up on different controller…

I’d suggest you hang in there and see if @JohnJohn has a suggestion on that controller… From what you’ve described, I’d be doubtful.

![]()

That’s a new one by me, but I’ll take a look at the manual.

I’m a proponent of controller swaps when things are untenable.

As I understand it , it was kind of working up until September 2023 when it was replaced with a new machine. It was offered up to me for parts (originally intended to convert to cnc router without having seen the machine) My son helped me haul it home and expressed interest in resurrecting it.

Everything seems to function individually but hitting run results in offset error message. (Not helpful just numbers) My thought was lightburn may side step this issue since I understand it controls the steppers and laser by itself.

LightBurn talks to a controller in a Laser engraver.

Drag the pics into this reply box. They should readily attach by doing this.

If this seems awkward, the Icon with the up-arrow pointing away from a horizontal desktop computer in the top row of the reply box is the Upload Icon.

If the controller is a GCode device, LightBurn 1.5.xx (still in development) may help get it going. If the controller is a DSP type, we may not have a workable answer (outside a controller swap).

My apologies I meant to suggest that it operated independently of installed windows printer drivers.

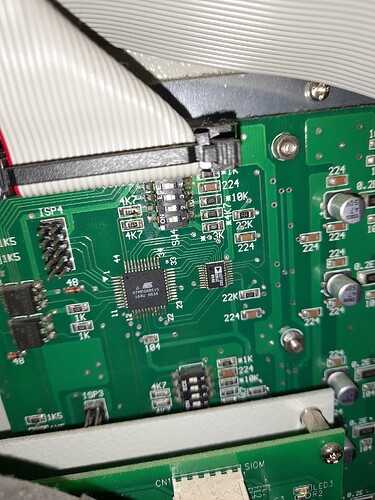

stepper driver board to rear(i think) atmega8515 chips

atmega 8515

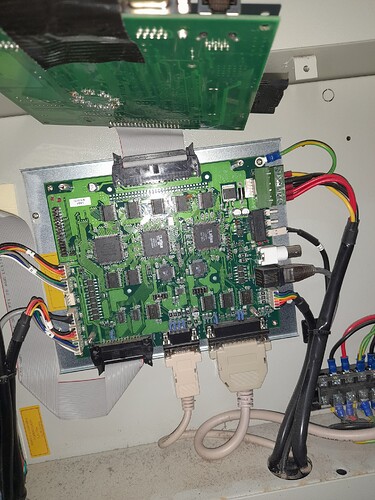

Mainboard on RHS (with comms board in front usb & network) Stepper board I think ? on LHS

the actual maiboard (comms board lifted away)

Interesting way to handle memory…

![]()

I’m not having a great deal of success with the existing hardware and drivers with this machine.

If i were to consider replacement of the control boards as you suggested, have you any suggestions as to which board(s) might be most suitable ?

A cursory google search suggests boards are available costing anything from a few pounds upwards to over a thousand pounds.

This being my first foray into laser etching/cutting i find my experience and knowledge base to be somewhat lacking when looking at the bewildering choice on offer.

Any assistance would be greatly appreciated.

Gcode or grbl machines are pretty low cost, larger lasers can use these, but many use DSP controllers like the Ruida.

Do you know if it has motor drivers on it?

If you can use some of the hardware it will save you money in the end. Mostly mechanical stuff…

I have some low cost controllers and a pair of relatively expensive controllers…

The controller drives the stepper motor drivers and also when the tube lases.

As with most things, you can get it to work for a lower cost but you pay for some of that in sweat equity…

Do you have more time than money or vice versa?

![]()