Hi all,

I have been having this issue for a little while now and not been able to get to the bottom of it.

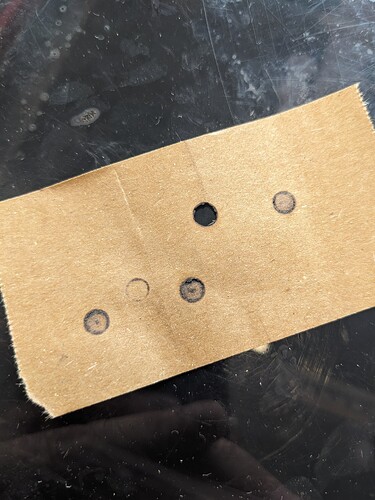

I have had this issue with a mantech 80w machine whereby the line scoring thickness differs in each corner of the bed very slightly. But when the material (MDF 4mm) warps by a few mm it will then go very thick.

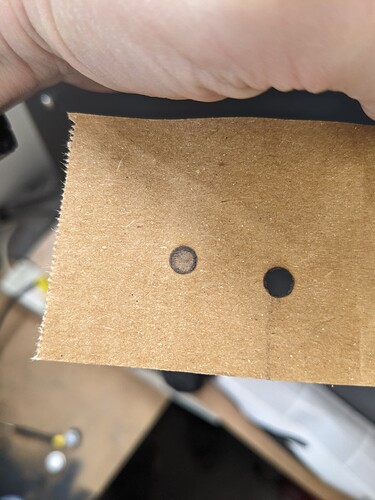

Attached is an example whereby the distance between the laser head and material goes out of focu by maybe 1-1.5mm.

I have a 2 inch lens which i thought had a 2.5mm tollerance for focus (maybe I don’t understand it though). My interpretation of this is that I have 2.5mm outside of the perfect focus point to stay in focus. I did a ramp test and with my nozzle it seems to be around 8.5 or 9mm.

I also checked all 4 corners of the bed and adjusted them to ensure it is the same from the bed to the laser nozzle head.

My other chinese laser is perfect though, I never seem to have issues with and the MDF material can be out by 2mm or more and it will still score perfectly fine.

Attached is a laser focus alignment video I did today. I had noticed that when going from Mirror 2 to Mirror 3 at the bed closest to me, the second pulse on the right hand side is slightly north of the first one.

This isn’t the case when you move the laser head to the top of the bed and go from left to right (it is then perfect).

Not sure if this is the route cause of my issues.

But have you ever seen when the focus thickness of scoring very quickly changes by just 0.5 or 1mm?

PXL_20240708_093712930.mp4

Hope you can help.

James