Hello,

I’m new here and quite new to the CNC/Laser and Lightburn world.

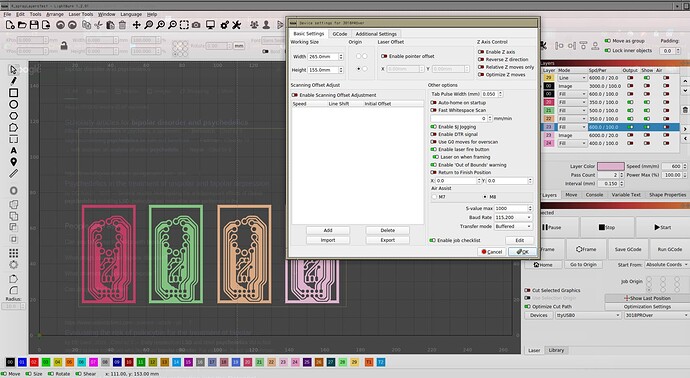

I’ve been successfully using this Genmitsu 3018 PROver for drilling and now I’m experimenting with the laser burning of painted PCB board for etching. However I must admit that I’m just pretty stuck.

I’m running Lightburn 1.2.00 on a Debian system and went through all the guides on how to setup the machine, the workspace and found several really great youtube channels/videos on this topic too…

I’m doing some testing to get the best combination between layers of paint and type of laser burning but I just seem not to be able to find a pattern on how and when Lightburn simply stop a job at random stages.

I’ve re run the same job twice and it stopped at two different points, which makes me wonder how this error can even be consistent or existing in first place (in the GCODE) as indicated by Lightburn:

Pretty common problem lots of people are having, although in my case the laser doesn’t actually stop firing, but just the CNC machine stops moving and the error comes out.

error:2

Numeric value format is not valid or missing an expected value.

On or near line 12118:

Job halted

Here are the Gcode (saved from Lightburn)'s lines around 12118, where Lightburn claims there’s a problem:

G1 X0.494S1000

G1 X0.1S0

G1 Y0.075S0

G1 X-0.1S0

G1 X-0.494S1000

G1 X-2.173S0

G1 X-2.166S1000

G1 X-3.364S0

G1 X-0.52S1000 (this is line 12118)

G1 X-0.742S0

G1 X-6.046S1000

$$

Here’s my current config:

$$

$0=10

$1=25

$2=0

$3=2

$4=0

$5=0

$6=0

$10=0

$11=0.010

$12=0.002

$13=0

$20=0

$21=1

$22=1

$23=3

$24=25.000

$25=500.000

$26=250

$27=1.000

$30=1000

$31=0

$32=1

$100=800.010

$101=806.294

$102=804.032

$110=2000.000

$111=2000.000

$112=600.000

$120=200.000

$121=200.000

$122=100.000

$130=300.000

$131=180.000

$132=34.000

ok

here’s the messages at software boot up:

Waiting for connection…

<Idle|WPos:0.000,0.000,0.000|FS:0,0>

<Idle|WPos:0.000,0.000,0.0

Grbl 1.1f [‘$’ for help]

ok

[VER:1.1f.20170801:]

[OPT:VZHS,15,128]

Target buffer size found

ok

<Idle|WPos:0.000,0.000,0.000|FS:0,0|WCO:0.000,0.000,0.000>

I can upload my working file and some photos of the corrupted job/PCB once I figure out how on here.

I tried different USB cable/ports with no success (hence this post), I’ve googled for days and I just couldn’t find a reason why this job would fail.

Any insight is very welcome, because I’m not going to keep wasting PCB on this and I’d love to bring my hobbyist project forward. Thanks you!