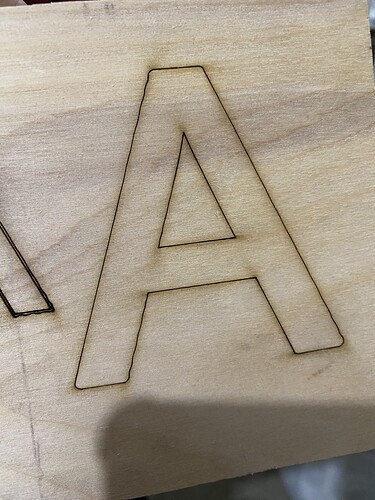

Whenever I set an exterior kerf I get wobble. This does not happen with manual offset or by a manual enlarge. It is extremely odd and I actually hear the cover shaking caused by the wobble whenever I set a kerf.

This user had the same issue so there has to be a solution.

It might help if you told us what the photos represent.

All of them have a wobble…

There should be no difference with or without a kerf.

![]()

All the photos are with kerf, without kerf it cuts perfect. I totally get that there should be no difference but there is. See the other post I referenced, I’m not the only one and I agree is makes zero sense but there has to be some kind of software-hardware error causing it just with kerf activated.

It starts at 40mm/s and up with Kerf

Without kerf I can go up to 400mm/s and get perfect cuts no matter the shape or corner radius . I’ve been testing for two days and it’s 100% just with kerf activated.

I’d suggest you follow what was outlined in the link you posted…

Oz made the suggestion, I’d follow it.

Make sure you put this threads link in your email.

This sounds more like a hardware issue…

Good luck

![]()

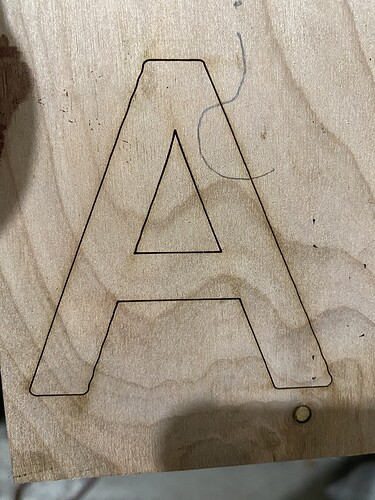

I made it wobble without the kerf, I had to go super fast, above 400mm/s and cycle through a few dozen fonts but I made it happen. So it’s looks like it is hardware. It’s just way worse with the kerf. I slowed down the corner speed to 40% in machine settings and as long as I don’t go crazy fast with speeds everthing looks ok. I am going to get a Laguna tech to my shop to fix this because everything looks tight hardware-wise. It’s definitely the x-axis. Thanks for everything.

My China Blue machine has had some changes and it will run at 1600mm/s + and mechanical issues really show up as you up the speed.

Most of my engraving is in the 100mm-500mm/s range, so the high speeds are really for messing around, you can’t really do much useful work at 1600mm/s.

It would be nice to know the issue…

![]()

So I spent hours on the phone with the Laguna rep. We tightened everything, reseated all the lens. Checked the belts, pulleys…everything possible and it’s still happening. Maybe it’s a stepper motor, I really don’t know.

Are you absolutely certain you’re ever reaching these speeds? This seems unlikely with these line operations unless you have a particularly speedy machine. I would suspect you’d be nearly always accelerating or decelerating.

It happens starting at about 75mm/s when I enable kerf offset. That high speed was without kerf. I also recently found some fonts that wobble at 75-80 with no kerf. They are the fonts that contain sharp corners. 75mm/s is always my first pass with mirror acrylic so I would like it to be steady at that speed. At 300-400mm/s the whole machine shakes at the corners. It’s kinda scary.

You really only have 2 strategies to increase speed. Beef up your hardware for more power and stiffness or make things lighter. Reducing mass tends to be the more practical of these… especially since beefing up the hardware often entails increasing mass.

So it’s common for wobble at 75mm/s on other machines? I’ve only ever had this machine so I don’t know myself. That’s not really fast to me and knowing the price I paid, I expect it to be at stable.

What is the height of the letters you’re trying to burn? They look on the larger side but hard to tell. For anything at typical smaller type sizes even 75 mm/s seems high but the hardware I use is most certainly not industrial grade.

Can Laguna support run your same files and test results on their tuned machines?

The problem with text ini genearal s due to the constant change in direction, there’s never really an opportunity to reach top speed… and higher acceleration requires ever more violent change in direction. It’s the unstoppable force meets immovable object scenario. This is why certain fonts suffer more from this than others. Designs with more curved shapes allow speed to be maintained more readily.

I tried all sizes, the one in the picture was 2.5 inches and it’s worse on Arial type fonts since they have the sharp corners. So if I use a magnifying glass I can see some wobble down to 50mm/s but whoever looks that close…but it’s there. That’s a great idea asking Laguna to run the file. I can def live with it but it’s just something that bothers me. What would I replace to stop it from happening? Wider belts and larger stepper motors?

This will depend on where you’re getting the wobble. I suspect increasing power won’t be that helpful and may actually make things worse. You need to increase stiffness and rigidity. Reducing mass may help.

To me it looks like the laser head itself is likely twisting around the gantry due to rapid Y movement but not certain. Try grabbing the laser head near the bottom of the head and pushing back and forth against the gantry. Can you feel flex there? If so, see if you can identify the source of the flex. The next challenge would be in eliminating that source.

I believe @berainlb is on the right track.

A normal head is built like a pendulum and acts like one when it’s mass is accelerated in any direction. Once it starts to swing, it will slowly reduce the osculation until it stops or more energy is put into the system.

Put some slight pressure at the nozzle tip and see how easily you can push it out of alignment.

I have a $2K China Blue 50W (ha ha) that has never shown this issue, even when new, so it should not be acceptable operation.

If I can think of something else, I’ll pipe up…

![]()

So trying move the head with the laser on, it’s does not move. I have to use all my strength to get any flex, to the point of causing damage which I do not want to do. Maybe this will help, the wobble is worse in the dead center of the machine. If I cut close the top corner it’s hardly noticeable(closer to the motor location). At speed I can see the belts vibrating, something is definitely shaking or off kilter. Then if I keep increasing the speed is when the whole machine shakes. I’m a just having major issues finding the source.

Since you are sure everything is right…

Might try an extreme adjustment of one axes belt, then the other. Take it too lose then too tight. Test it in the worst area. Just to ensure you are at the best belt tension. I have never noticed my belts vibrating, I think I would have notice it.

You might have to take some kind of tact to locate the issue.

What does the vendor say? I wouldn’t think this would be acceptable to them.

![]()

Yea, it is actually the whole machine vibrating but it’s visually evident looking at the belts. You can see the vibration. That is why I was thinking a bad motor originally, maybe a stutter on deceleration. But I am not an expert on the characteristics of a failing stepper. So with laguna, I also have a CNC. Support for CNCs are world class. Support for their lasers leave a lot to be desired. If I can’t figure this out I will have to schedule a service call. They prefer sending out the part and having the customer installing it themselves as they did when my power supply was failing. I will try the belt adjustments to extreme and let you guys know. Thanks for everything guys, truly appreciated.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.