I’m very new to lasering - I have a sainsmart 3018 PROver with the blue 5.5w laser module kit. I cannot get the laser to work so am guessing I haven’t set this up correctly. When I press the fire/PWM button in the laser stays on permanently so I know it works. I just cant get it work with the fire button using Lightburn - I’ve followed tutorials but cannot figure out why it wont work. I’ve spent about 2 days trying to sort it out and am on the verge of giving up! Can anyone help please? Thanks in advance

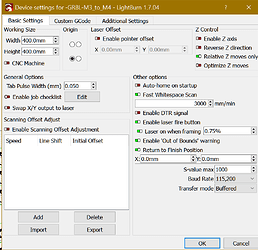

What is your power set to under Edit > Device settings?

On LightBurn Cknsole window type $i then press enter key, type $$ then press enter key.

Copy / paste here all the output.

Hi - thanks for the reply - this is so frustrating!

ok

$$

$0=10

$1=25

$2=0

$3=2

$4=0

$5=0

$6=0

$10=3

$11=0.010

$12=0.002

$13=0

$20=0

$21=1

$22=1

$23=3

$24=25.000

$25=500.000

$26=250

$27=1.000

$30=1000

$31=0

$32=1

$100=250.000

$101=250.000

$102=250.000

$110=1000.000

$111=1000.000

$112=1000.000

$120=30.000

$121=30.000

$122=30.000

$130=290.000

$131=170.000

$132=40.000

ok

Also does the bottom 3 pin socket need to be connected - I cant see where this would go. I’m using mains power

I’ve tried the above settings - no joy unfortunately

Can anyone help?

As a good practice always insert and remove your machine plugs with power and USB disconnected.

-

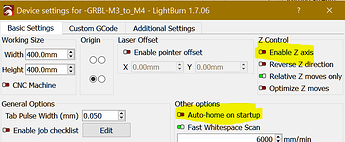

Post a screenshot of Edit > Device setting.

-

Can you post a better picture of the selected zones were we can read the letters?

-

Post a picture of the connections at the other end ( laser module).

-

Check if your 3018 controller has a switch for laser.

-

If your 3018 has a hand controller unplug it and try again with Lightburn.

-

At last try with LaserGRBL program and report back.

Hi

Thanks so much for all the help - I think I’ve fixed it. Just need to understand how to home the laser to an origin point and where to out my piece of leather in two to the image

Read this Lightburn doc:

Do your tests first in cheap cardboard.

Thank you!

Forgot this one:

Happy lasering.

Fingers crossed

Thank you for your help!

Does anyone know the typical $100, 101 & 102 values should be for a 3018 PROver

The image I’ve designed is so much smaller that the laser engraving and I wonder if these setting are wrong

Thanks

C😀

You can calibrate your axes.

I see some 3018 with lead screws and different values, but if you´re getting bigger output maybe 800 or 1600.

The number may not be a round number just a ref when you calculate the values with the above “tool”.

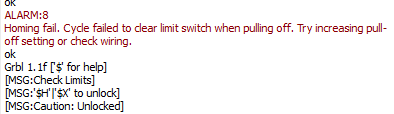

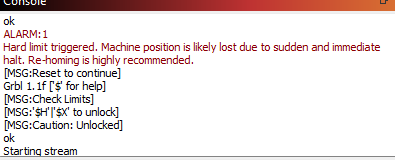

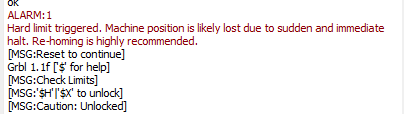

Thank you - it seems to be two steps forward and one back at the moment. I’ve sorted the above issue, but I keep getting a “check limits” message

The machine seems to be stuck a third of the width in on the workspace (300x180 is what I’ve set $130 & $131 to) Also the position of my text on the computer isn’t the position on the wood in the machine. The must be some settings that I haven’t got right!

Check your $27 setting. That’s the amount of pulloff in homing. It is typically 1-3mm.

Set $27=3

A bit of info on GRBL settings:

https://github-wiki-see.page/m/gnea/grbl/wiki/Grbl-v1.1-Configuration

Solution for some errors:

.

Keep width = $130 = 290 and eight = $131 = 170, they have to match.

Report back please.

Hi

Thanks for the reply - $27 is set to 3. I changed £130 & 131 and the work space to the figures sent. Pressed the home button and it crunched the gears with these messages

I dont know how to check the limits? It just stops a third of the way across the board

Its v frustrating as everything else seems to work ![]() - see photo

- see photo

Hi again

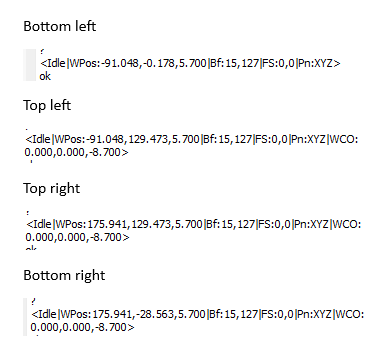

I think it is soemthing to do with the settings of the laser at each corner of the work area. below is what Ive recorded. Are these wrong and how do I alter them - via the off set but dont know how to work out the correct numbers

- Unplug your 3018 (power and USB)

- Disable Auto-home and Z axis.

- Reconnect the 3018.

- In Console type $HX press Enter $HY press Enter to home axes individually.

- Check if the machine runs a small project.

If you still have troubles type $RST=# press Enter and check again.