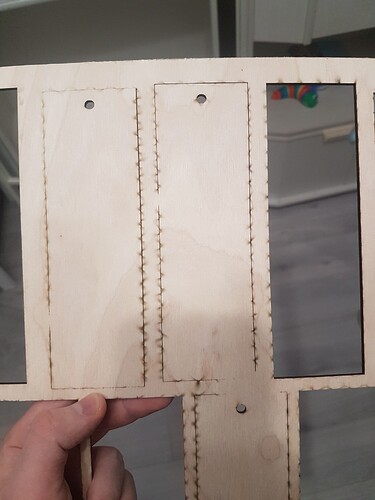

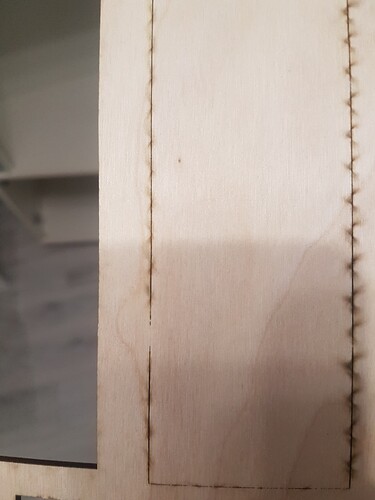

Good day, new here and new to lasers. Thought this might be the only place where I can get help, so here we go. I have Ortur Laser Master 3 LE and im having difficulty cutting through 3mm birch plywood, sometimes I have no problems but other times im just wasting material because it seems like my laser cannot cut through certain areas. At first I thought that this might be issue with the wood that I use and I know that theres a lot of other ‘‘junk’’ inside these ‘‘laser plywoods’’, but now im not so sure. Could this be because my laser is not getting constant power in the corners? But its weird because it can happen in other places as well…even if I make additional passes with higher power and lower speeds it still doesnt always do the trick. Mind you, I am doing 15 passes with speed - 1800mm/m and with max power 79%. Of course I can cut it through with very, very low speed and 100% power but I get really disgusting burned edges that smell really bad. Any advice would be appreciated., thank you. Added some pictures.

Odd looking pattern. Have you done material tests?

Have you removed and cleaned your lense-- presume its a diode laser ???

Yes, multiple times with low speeds from 100mm/m to 400mm/m and with higher speeds like 800mm/m up to 1800mm/m

Its a diode, yep im cleaning lenses all the time when im finishing my session

If your laser is well-trimmed and your focus perfect, then it’s the material that’s causing you problems. It is a “normal” phenomenon. “Us” with stronger CO2 machines often have the same problem. Glue and knots in the wood, often in the cheaper plywood, cause problems. There is “laser suitable” plywood with interior glue and a few studs, but it costs more.

Even if I just turn up the power, plywood with these problems is often black around the edges and has holes when the laser has been there.

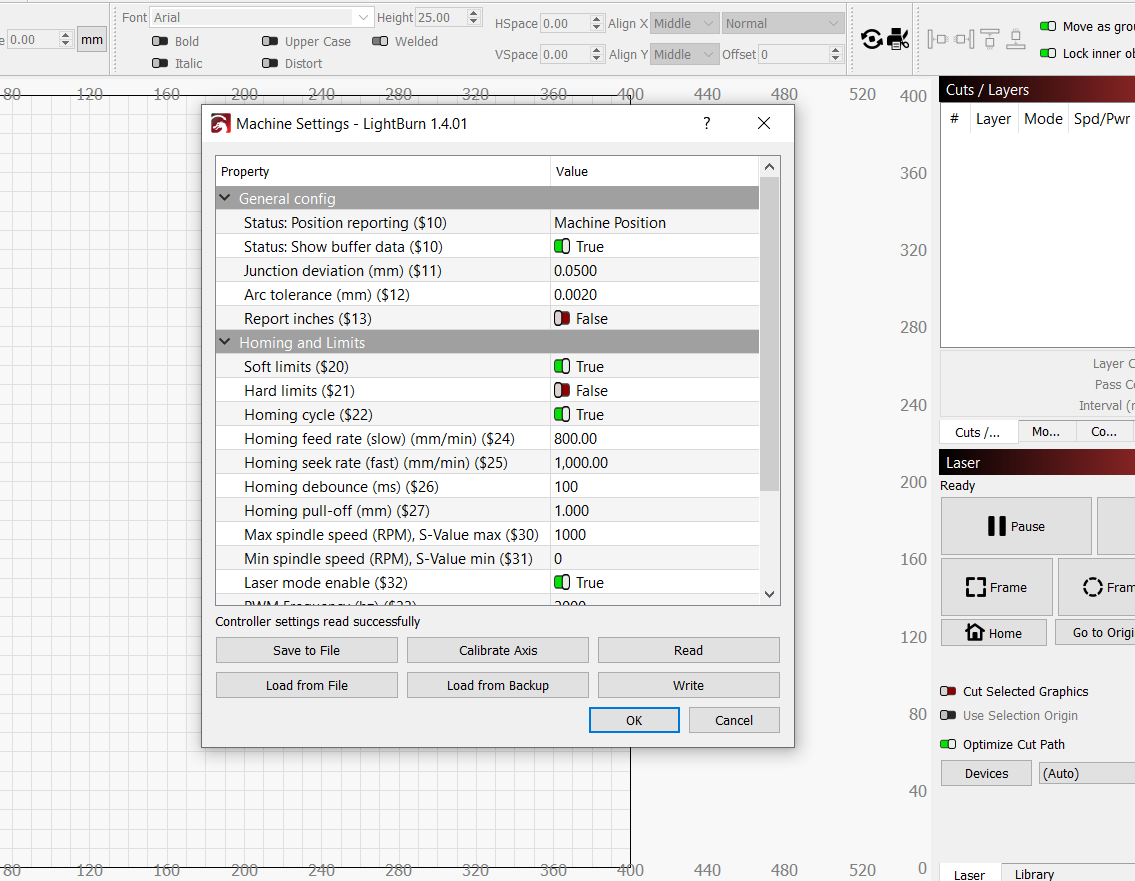

Make sure your cut layer is set to constant power mode. If not itll reduce speeds at corners. Set min and max power to same value. Make sure power is at like 97.5% for your diode.

Im sometimes getting these randon blackened edges as well, is this what you had in mind? Other coasters and bookmarks turn out to be fine but sometimes with the same settings I get these either smaller or bigger blackened ‘‘dots’’, and yes im using a bit cheaper laser plywood which is sold in much bigger sizes (5 feet) than the standard ones (like A4 format) because I thought well they`re selling the same product and just want to make more money here.

I can only set max power for some reason, min power is greyed out for me in lightburn

I buy cheap underlayment and have had few problems so far. Some voids is all.

Those voids cut through easily? What would you do in this situation, lets say I spend 12 minutes engraving and then my project doesnt cut through…and I try to make few more passes but not working. So I just wasted ~15 minutes of my work, how can I overcome this? Do you throw the material away? Should I buy other plywood? Im just curious what to do with wasted time and project at this point…lets say I have 3 such projects in a row, thats a whole lot of wasted time

I also have “cheap” plywood, but I use it for tasks with relatively many smaller parts that are not too time -intensive. I have a very powerful lamp that can sometimes reveal stored things in my boards, but thicknesses above 3mm are also not possible to see again.

I have long since quit trying to repair parts that do not fall out of itself when everything else behaves normally. It takes me too long and still has edges that are not good enough. By “rough” parts in e.g. 5-6mm which are typically relatively large, however, I spend time saving them.

PS. It is also a reason why I love working with MDF and HDF, here you have a completely smooth cut throughout the plate and it is cheap.

PS.2 for “Art” projects or my lamps I use “Aeroplan Birch Plywood Interior Limeted”, it costs 50% more like the “cheap” plywood but is (almost) free of knobs and glue pockets.

Oh man tell me about that wasted time. That was #1 thing I hated about my diode is I couod never source quality thin material. Now that I have co2 I use maple veneer MDF and its flawless cuts every time.

With the diode I would run 2.5hour plates and had a 30% failure rate because the wood qualoty was so pocked with glue hard spots of filler that wouldnt cut through. It was so bad I had to start calculating in 30-40% failure rates in my material for a job…thats what I got for going cheapest route I guess. I was using underlayment from lowes at $27 a pop for a 4x8 full sheet.

I would definitely suggest changing materials…itll help you sooo much.

Maybe just lucky but my failure rate on underlayment has been about 5%

Thank you for your input, I guess i`ll just have to deal with it or buy better plywood. Quick question, I have heard that I can make smoother cuts in my corners by changing acceleration or start speed from default ‘10’ to ‘100’. But I dont see any of thess options in lightburn?

Sorry for the late feedback, unfortunately I can’t help you with the settings, I have no experience with an Orture Laser.

In my CO2 laser I vary my min. power for this purpose, which prevent e.g. too much power/black corners.

Understood, no worries, thank you for your feedback

Thats a very good failure rate…probably depends on the supplier quality

wow, hopefully I can avoid that, as you said the cheapest aint always the way to go…its just too bad that I dont have much suppliers in my area.

I am in the same boat material wise. None of the big box stores sell any material diode friendly…its all 5mm+. I had to drive 2h to a menards to try and find decent stuff.

When my sister ordered 500 ornaments for her school, by the time I was done I had ordered a co2 laser…monport had a payment plan super deal for black friday so I grabbed it. Not a single regret on upgrading…I can even one pass cut 7.5mm poplar from my own harvested tree I ran through my neighbors lumber mill. The more I use co2 the more I realize diode should be used for dark engraves / cutting CONTROLLED QUALITY 3mm MAX materials. The headache just isnt worth it. Heaven forbid you are in some time crunch or low margin situation, as youd definitely be paying them by the end with a diode!

If you can find 3mm veneer + MDF core youll be in business with no headaches I promise.