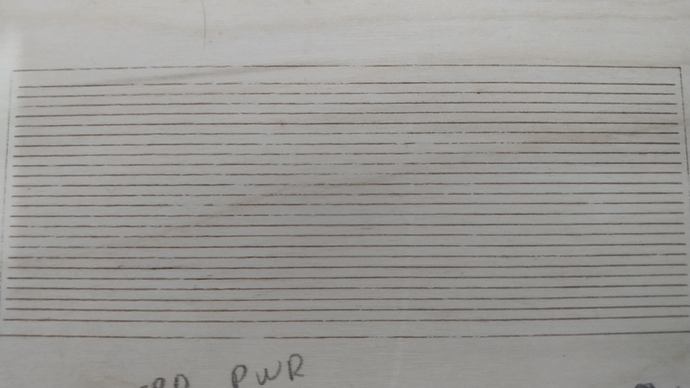

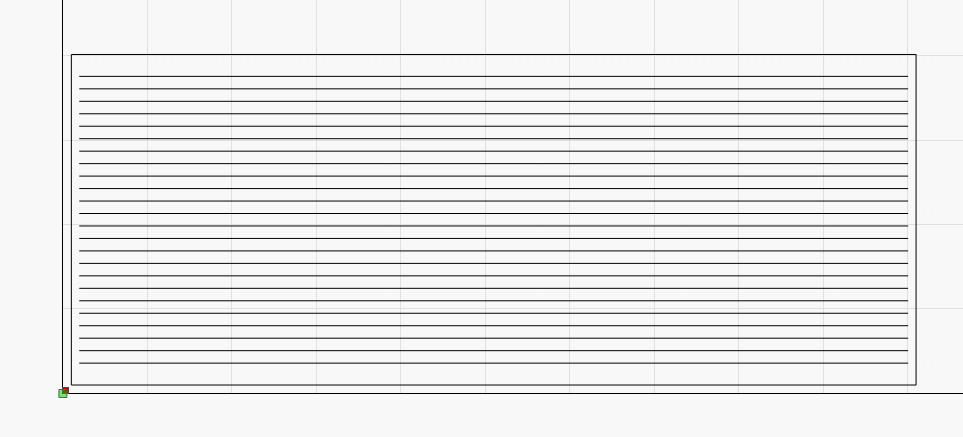

After reading this post link i made a line test.

As you can see the laser starts/stops where is supposed to BUT for some reason the lines isn’t consistent and i can’t understand why…maybe it’s the wood? marlin dont send the correct power? laser is out of focus?, to fast? i don’t have a clue.

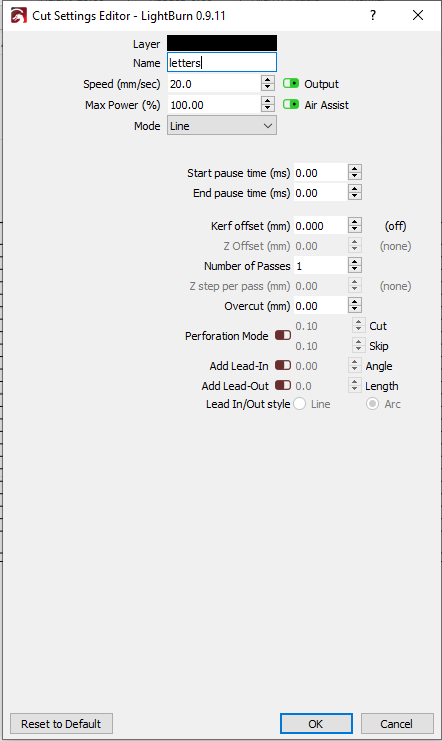

the txt file is my gcode

test_LINES.txt (1.7 KB)