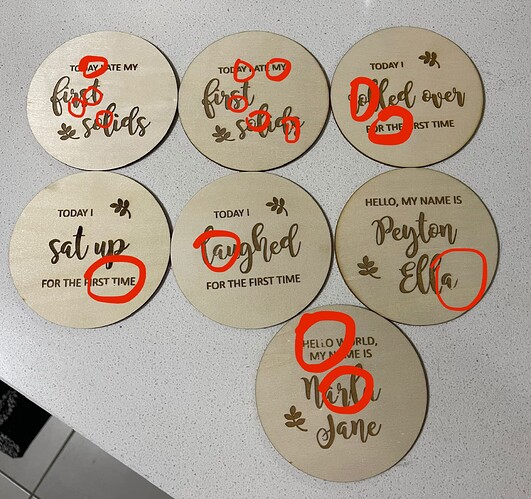

Hi there, could someone please assist and advice why there’s some parts on the engraving area that doesn’t get engraved from Ortur Master 20W. Photo below - you can see it’s meant to say MONTHS OLD but some spots missed.

I really don’t know why this keeps happening and it’s wasting time redoing it for my sets it happens all the time. Any advice or possible fixes please is appreciated.

Has this problem occurred recently?

Has the engraving ever been done correctly?

It’s been happening since I had the laser a few weeks ago. I started with 12 discs in one run as pictured below there will always be some discs that’s not properly engraved completely and this happens all the time in random discs so I end up engraving 3 discs at a time still having issues, then I have to redo one disc that has an error and it works.

I’d like to run 12 discs in one go with engraving without issues. I don’t know what the issue is. I’m looking for any ways to make this stop happening so it’s not a waste of time for me redoing errors. Is there a chance at all I can have a complete error free run on 12 discs?

That’s likely to be wood color, grain, focus, or some combination of those. Lighter wood will reflect more of the energy from a diode, and the thin sections are more likely to have this issue. If you slow down or increase power, it will likely help.

Thanks. What would be the ideal settings for this type of wood? I have adjusted the preferred power for depth. Somehow it just chooses random spots not to engraved.

It would be helpful to know what type of wood it is.

Birch plywood

If your problem is due to the color of the wood, I suggest spraying a mixture of water and baking soda on the wood surface and engraving on it after it dries, in which case the result will be excellent.

Thanks I will try that. However I still don’t understand why on some runs a disc is perfectly engraved then the next run it could potentially have missing spots and all wood is the same. I’m not sure if it really is the wood that’s an issue or the settings in lightburn. I might have a play around in the cut settings editor and do some more test.

Do what I said and tell me the result. I hope your problem is solved

Thank you definitely will try that first

Ana, BB plywood is an “artificial” product, composed of 3-4 or even more layers of wood veneer with glue in between each layer. During the manufacturing process itself, glue may occasionally appear on the surface, either accidentally or to cover a crack or a small bump. Although the glue is manually removed, dried off and the entire plywood board gets a mechanical sanding, there is sometimes a thin film left. The glue in Plywood is what makes it difficult to cut it. You probably experience that sometimes a subject does not fall out completely or is more black / burnt than the rest, it is the glue’s fault. You can experience the same effect when engraving, typically if you engrave with low power.

You could try testing a bit on one of the discarded items, to find out how high you need to go with your power, to avoid this problem.

The proposal that Askan comes up with is a in this case not usable for baking soda solution does not penetrate the glue on the surface I talked about in the beginning.

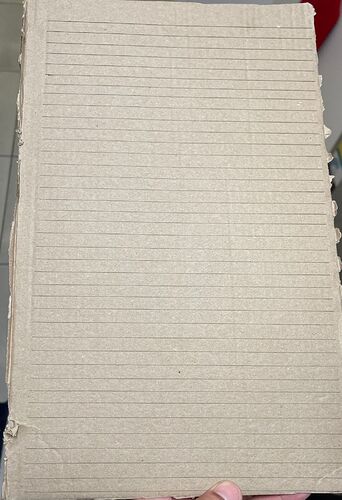

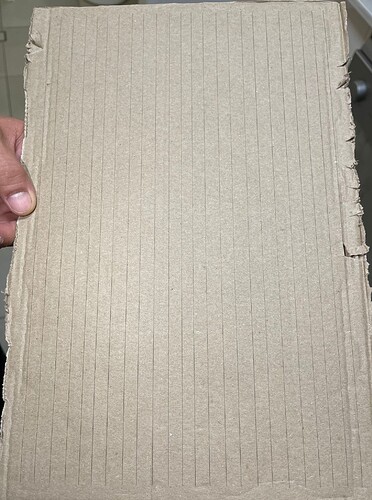

In the picture, the small bright spot, it is a small patch of glue which has “impregnated” the surface right here. You will not see this mark on the original, untreated plate. (it is not a spot I have overlooked, everything is sprayed twice)

By the way, I use the soda solution to make my BB Plywood darker, but it requires four extra steps in the work process.

Thanks Bernd for this great info. In this case with attached pics below, could it be the plywood colour and the glue as well? As it seems that it’s constant occurring in these sections at the bottom of the letters not completely engraving or could it be something else?

No, here I do not think it’s the plywood’s fault.

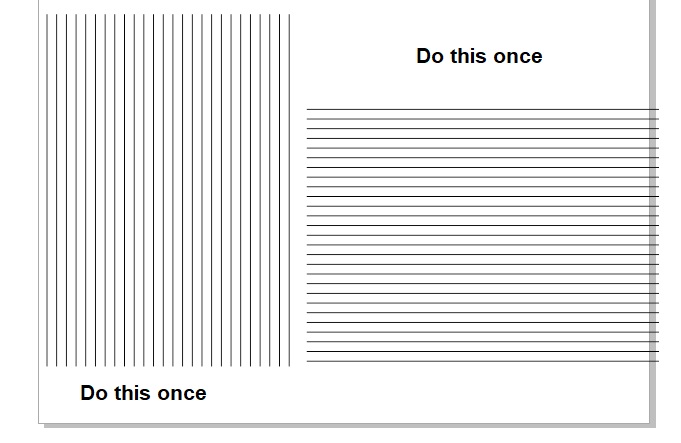

How fast do you engrave? It is a bit suspicious that the problem is only in one direction. An engraving with the same items but rotated 90 degrees may indicate if it is a machine or setting problem.

But apart from those flaws, your engraving is very nice in color and depth I think.

Ana, what is “Fichna2612” for a machine ?, I can not find information about it.

Speed settings is currently at 800 and power at 40, what should be ideal? Laser is Ortur Laser Master 2 20W.

So the recent one that was done, here’s the mistakes in random spots as well not just the bottom letters.

ََAna,Engrave a number of parallel lines along the x and y axes to ensure laser performance and see if the intersecting line .

Do this on the whole machine workspace, you can do it on a piece of useless cardboard

I mean something like this:

Will try this and let you know the outcome. Thanks.

hi ana,Well, it seems that the laser is not a problem, most likely the problem is made of wood, I suggest you use the LaserGRBL software, this software works very well with your machine(Ortur), so if the engraving is still a problem, it is definitely a problem of wood. Otherwise, it should be concluded that your machine does not communicate well with the Lightburn and some things are lost.

You can also test the design you engraved on the wood, on cardboard before using the laserGRBL software to make sure there is a problem with the wood.