What LP4 firmware does the Lightburn console report when you connect to your LP4?. My LP4 doesn’t recognize ANY instructions from Lightburn.

I assume that you have contacted Laserpecker support about you issue. What did they say?

What LP4 firmware does the Lightburn console report when you connect to your LP4?. My LP4 doesn’t recognize ANY instructions from Lightburn.

I assume that you have contacted Laserpecker support about you issue. What did they say?

This is confusing me a bit. LightBurn was communicating to the controller in post #5 was it not?

Communication with my LP4 is one way. The LP4 sends the (wrong) firmware revision and connects to LB, but does not respond to any commands from Lightburn - nothing happens. On one occasion, after I fiddled with the LB device settings, the LP4 did fire the 450nm laser but only a diffuse blue light came out. Presumably, the laser was hard into the stops - outside the range of motion and the blue light coming out was a reflection from the inside of the housing. I figured that this was probably not good for the innards of the LP4 so I haven’t messed with the settings again.

Hopefully, if enough people complain to the LP support about incompatibility with Lightburn, they will fix the firmware.

This is supposed to be the link to setup LaserPecker 4 for Lightburn. Did you follow that? Is that were your 6.53 version information came from?

https://laserpecker.feishu.cn/wiki/X4CWwRap9iCxt7kU2v9cNs90n7f

If you use the console in the cut/layer window, power on the LP, copy and paste the output here.

The first line or two usually displays the version number…

These are from saintsmart $I should give you build info.

![]()

That’s not entirely the case. The controller was receiving commands and responding to them. Note the responses to $H, $#, and ?. You can see the controller also reporting laser module being used. There’s definitely some level of communication happening.

The question then is what’s the disconnect between that level of communication and proper function.

The link states

That may be the issue… might have to make a plea to LP if you can’t get a proper firmware upgrade.

![]()

I followed the firmware update instructions to the letter. My Lightburn Console reports V6.5.2. The LP4 Windows Design Space reports V6.5.3 - up to date. My Lightburn is the latest revision. I have repeatedly asked LP support if there was a way to force a reload of the firmware update and the only response I got was that I was using an unlicensed cracked copy of Lightburn. I didn’t know that there as such a thing. The LP4 warranty is invalid if unlicensed software is ever used with the LP4 - my license is up to date and valid.

Whatever firmware that is loaded in my LP4, it is not compatible with Lightburn. I probably should give up until the LP folks issue another firmware update and just use Laserpecker Windows Design Space and import files from LB. Not the cleanest solution, but it works.

Yes, it has been stolen, so to speak…

Use Lightburn console and copy the boot message with the software version… copy this and paste it into the email to LP.

Advise them about having a current paid for version of Lightburn and that their phone software says it’s updated, but the machine reports differently… You can use any terminal program to talk to grbl, so you can something besides Lightburn to check the version… eliminating the question of it being stolen.

What the machine reports is what it is… You can enter a $I at the console and it should echo the version information…

Every site for that I’ve been to with any technical information is Chinese, like the link I posted.

I think that’s what you are dealing with and you have to keep on them until they understand the issue is. If this is the issue, they need to fix it… or give you a solution… it’s advertised that it can use Lightburn… I’d hold them to it…

Squeak long and loud enough, it will usually yield results… you have nothing to lose…

If you purchased this with a credit card, you may have the ability to pressure them with a refund. I think you just need to make them understand they need to make it work… with your good copy of Lightburn.

I don’t know about you, but I’d go off on them for calling me a thief.

![]()

I use LightBurn as well. I have v6.53 running according to the Design Space app on PC and Android, but in console it states v6.52.

It works, but is a completely closed GRBL communication. A lot of commands do not work and nothing is being stored on the LP4. Everything is being streamed/buffered. This makes it really buggy imo. I have had quite a few problems when doing big engravings. The data stream get unresponsive and the laser will stop moving, but still be on which is really dangerous.

They need to find a way to let it act like a ruida controller. This way you can add 2 laser sources and send files to the LP4 storage. Running the engraving job from LP4 storage, will have benefits such as higher engraving speeds as the streaming serial protocol can limit the speed the laser can run.

Also the laser power curve is not right. The laser has 0 - 255 signal for the power of the laser, but 1% in the Design Space is the value 130 for power according to their instructions.

This will give weird artefacts on the engraving at the edges.

GRBL is not the communication protocol the LP4 is designed for.

Not only LP4, but also xTool F1 has the same setup and problems with LightBurn.

It would be nice to see LightBurn working together with LaserPecker to let it use their communication protocol. Maybe it would be possible to let Design Space act as an bridge to make the right translation to the LP4.

Just thinking out loud here🤔

Most GRBL systems behave this way and work without issue. So it’s not something inherent in the model. Even offline systems work this way and happen to have an integrated system that’s streaming to another integrated part of the solution.

Typically if this occurs it’s due to a loss in communication. This is fairly well documented at least for other lasers. Bad USB cable, noisy electrical lines, static discharge, etc. can all cause this.

Note that if disconnects are happening during streaming that this would likely also be an issue even with an offline model, just less apparent.

As you can see here.

LaserPecker Design Space on top, down is LightBurn. Same speeds, same power, same resolution. Could be combination of acceleration settings and power curve.

Thanks for dropping in and clarifying the use of Lightburn with the LaserPecker 4… I’ve had my eye on these for a while, but they are still rather pricey…

If I remember correctly, Lightburn has tried to work with them but they are not interested. I will stand corrected if this is not the case… I remember a thread with a similar question a while back.

The are a few Ruida I know of for a galvo, one is the RDM4024V-PCI-R-FIBER… it runs about $3,400 for just the controller… It’s the only one I could find that I could actually purchase…

I suspect the control information is also different from a standard Ruida.

Every reference to technical information seems to be based in China . The site with the information is laserpecker.feishu.cn, definitely Chinese…

I think the whole thing is Chinese.

How do you know this? Is this just for the 1064nM or both?

Since these appear to be yag laser, I wonder if this is a constraint…

Thanks for the photos… Why do you use mm/m instead of mm/s…

I can run 4000mm/s on my galvo fiber…

Even your slowest speed of 6000mm/m is 100mm/s.

I don’t think I’ve seen anything mechanical that is faster than most of the serial protocols… If it’s waiting on anything it’s the mechanical response.

Galvo, like a regular machine is just a different kind of stepper motor equivalent… Not saying they work the same, but the software/controller can’t move faster the mechanical part of the machine.

I don’t know what Design Space is, really, I’ve seen that I can download it to my phone, but not install it on any computer… Is this also Chinese software?

Thanks for updating us with real world experience with these… they are really fascinating…

![]()

I have done all that you recommended. I did just yesterday get a response from the LP support “You don’t need to update the firmware, in LB, 6.5.2 corresponds to 6.5.3 in LDS. It is the latest.”

The problem may very well not be entirely in the LP4 firmware. Every time I try and run a simple file to LP4, I get different results. Sometimes nothing happens, sometimes I get just a blob of blue light (laser into the stops), sometimes I get a nice focused spot when the laser is fired, and sometimes I can see a bit of blue light moving, like the laser is into the stops on one axis.

I mentioned this in a previous post - LB dropped all of the LP4 devices as well as my modified and re-named GBRL device for no apparent reason, leaving only GBRL. I reloaded only the LP4 device. Yesterday, the two other LP4 devices (rotary extension, slide extension) just magically re-appeared in the device list. Something is not right, and I am going to look into it further, maybe writing a short macro file and sending it to the LP4 and see if it responds correctly. Also, I will try removing LB and re-installing it.

This seems to confirm you have the right firmware as @Robin0 stated, and has it working… with some caveats…

Their explanation indicates how the software reports it’s version number is a problem.

They could have stated that when you first queried them…

I don’t know what to advise at this point, not having one of these.

I think @Robin0 is probably better equipped to help you since they posses a complete working model…

Good luck

![]()

I found the problem! (I think).

My LP4 is now about 90% compatible with LB - frames, shapes, text, select wavelength (but doesn’t change the LP4 screen).

The problem was that the LP4 HAS to be run in the absolute coordinates mode. I run my ATOMSTACK in the Current Position mode. When I load the LP4 device, the coordinates mode doesn’t change, and apparently the Current Position mode really buggers up the LP4.

As they mention in their instruction: “The LP’s power setting in the App/software is 1%-100%, which equals Power:130-255 in LightBurn.”

LightBurn only doesn’t allow to set a min S-value. Only then I would be able to compensate for the weird burn at the edges.

I use mm/min as it is “common” for diode lasers. But I do prefer mm/s.

The LP4 was advertised be able to achieve 2000mm/s engraving speed and 16000mm/s preview speed.

Currently in Design Space you are limited to 24000mm/min (400mm/s) engraving/cutting speed, but preview speed is extremely fast as you can see here:

(filmed at 480fps, square was 140x100mm, only available in Design Space, I did a rough calculation: I counted 18 frames for it to travel the circumference of 480mm. So 18/480fps=0,0375 sec, 1/0,0375*480=12800mm/s preview speed, so I assume it is indeed 16000mm/s preview speed.)

But with human eye it is flickering solid.

LightBurn can achieve 50000mm/min (833mm/s) but for both preview and engraving/cutting speed as stated in their Parameter Equivalence Chart

They have all platforms covered, but the best maintained is first Android and second Windows.

Yes, that is what I first found out in the Facebook-group.

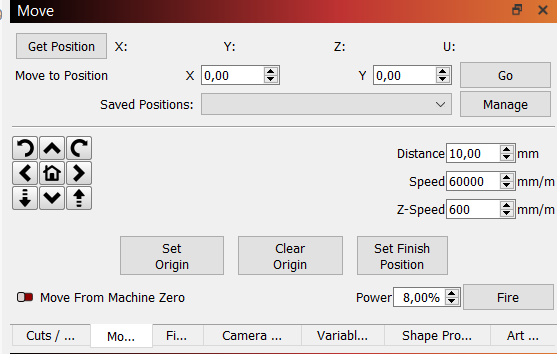

You can also use the “Enable laser fire button” in the settings. Then you can open the move-tab and be able to turn on the laser at a certain %. I use 8% for mine.

Keep in mind to first use the 450nm macro to enable the blue laser as you won’t be able to see the IR laser but would still turn on.

You then can click on the highlighted button and select 'Move Laser to Selection Center. This way you can see the blue laser in the center of your selected object. This gives a way to position your object. (This is not for finding the right height with the two red dots, these can’t be turned on from within LightBurn yet. I will assume they will add another macro for this.

This actually wouldn’t be beneficial since Min power values are not something that’s passed to the controller. You can get all the benefit of this by not going lower than 51% for your power settings if 130 truly equates to 1% power.

For grayscale, use 51% as the Min % power value.

What could potentially be more beneficial would be to have a way to rescale power percentages between 2 S Values.

On my LB with the LP4, 5% is the minimum power that will turn the LP4 laser ON. The comparison chart they publish doesn’t make much sense to me since LB power is in percent, not 0 to 255 unless there is some setting I don’t know about.

After finally getting my LP4 to more or less work with LB, I’ve found a number of small issues that make LB less desirable to use than LP Design Space for Windows. V2.2.2 DSW is pretty solid whereas LP4 with LB is a bit flaky for now. I assume that the LP folks will fix all or most of the issues with the next firmware revision. They really rushed to get the LP4 out the door without fully debugging the software. They fixed the major bugs in DSW pretty fast so I believe they will update the LP4 firmware to better work with LB relatively quickly.

Percent gets normalized to S Values. Where 100% = S Value Max and 0% = 0.

I think that would work for grayscale, but this happens when I use the fill option, the weird artifacts appear with shapes. And with fill you don’t have the option for min power. I also tried the overscanning option but I still get the same results…