Hello friends, I come to fill myself with wisdom. In our machines we have observed deficiencies in the cuts, solving by changing to a new tube. My questions are. What parameters can I observe when the useful life of my tube is already fulfilled? If they are 170 W tubes, how long is the useful life working an average of 12 hours a day. Thank you very much in advance.

Each manufacture will specify a working life for the tube, usually between 4000 and 10000 hours. That lifespan can be much longer if you keep the tube at a lower power and keep it cool. If you really want to extend the life of the tube, keep the max operating current about 70-80% of max. Also keep it below 20C, you can significantly extend the life by keeping the tube around 15C while cutting.

What is the max current rating for your tube ?

The gasses quit combining properly as the tube age, at least in layman terms. This can be from shelf time to operational times. I don’t know of any specific time frames and I suspect from my time around them, it’s more of how it was manufactured (accuracy) than anything else.

These commonly go out of TEM00 mode or resonance. This effects how the beam is formed or it’s quality.

They can resonate correctly but still start loosing power because of degraded gas mixture.

My understanding of the placard is that rated power, is the tubes 100% power rating, whereas the maximum peak is the do not exceed power limit. So these are really 150W tubes… at least IMHO. I spoke with a number of people that should know.

Most tubes of this size are generally warranted for 10k hours. They are also analog devices, so they run longest at mid-range. You can run 150W, but anything that’s analog and you drive it at 100%, it generally shortens the devices life. If it’s measurable or not, I don’t know.

I run my tubes at 20C (68F), I think temperature being cooler helps keep everything working.

I’ve spoken to people with 150W machines that failed out of the box as a bad tube and I’ve been told by someone who has had the same machine for over 10 years running 5 days/week 8 to 10 hours a day.

Many of the smaller consumer co2 don’t seem to make 10k hours. One of the guys has a K40, expected life in best case according to OMTech is 700 hours, he’s run his for 7 years.

I assume you have mA meters on these and that the lps is set at the proper current limit for your device… If you don’t do this you may get more current through the tube than desired. If you adjust the lps for your tube current limit it will synchronize with power settings in Lightburn (or other software package).

Good luck

![]()

I’m not aware of what a laser machine you have with 4 tubes, but “normal” Chinese tubes are very rare similar, even in the same batch, when we talk about smaller powerful machines 40-80 watts (?). Therefore, it is also rare that we can use each other’s settings for precise reproduction.

A CO2 tube usually does not die from one day to the next and you will be able to compensate for a given time for the tube’s deteriorating effect by turning up the output effect on the machine. But it only goes in a bounty time. Something completely different is it if the tube is not in TEM00, then most often it cannot be used (for production) anymore.

The lifetime depends very much on how the tube has been treated. Has it always run on max effect?, Has there always been the right cooling without air bubbles?

The max effect on my nominal 60 watt tube is about 18ma which corresponds to 65% in LB, then my tube doesn’t give extra power, no matter how high I set it. I stick to the limit and think my tube is fine for the additional 1-3 years. But I don’t produce as much as you at all, I have effective 4 hours/day laser operation and in summer I mostly hold a 2 -month vacation, in this league I play.

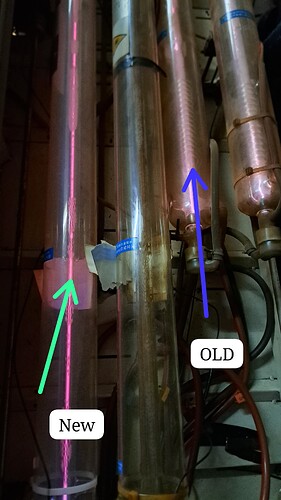

When I see your pictures I am a little frightened how your silicon hoses look, they have been getting dirty water for a long time … I will change it all out of the and inspect my refrigeration machines, they do not look better inside, I think ; -)

If one is to believe in what is in the descriptions of 100-180 watts tubes, then they have a lifetime (with full production), of approx. 2 years.

20 milliamperes

Hahaha, they only look dirty on the outside, we are changing the drinking water for demineralized water with refrigerant, the hoses are purged. Just like the chiller tanks. Generally we produce 120 pieces per day per machine, the cutting cycles are 12 minutes, with 20 mA.

There are times when my production is large and I have to do double shifts with 1 hour breaks on my machines, the first shift being 9 hours and the second being 8 hours.

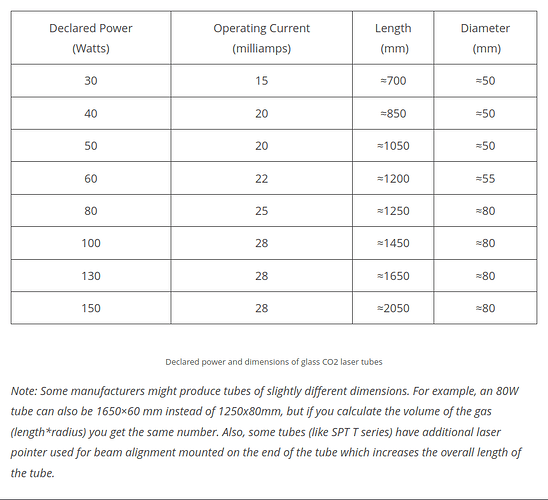

That sounds actually quite low for a 150 watt tube.

You could likely push the tube much higher. Some manufactures specify up to 28 mA nominal.