the movement tab works fine as for now

sry i misspoke. i ment to say : i would like to continue to fix it ![]() just for my mental health

just for my mental health ![]()

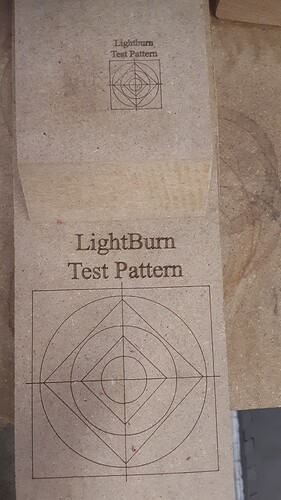

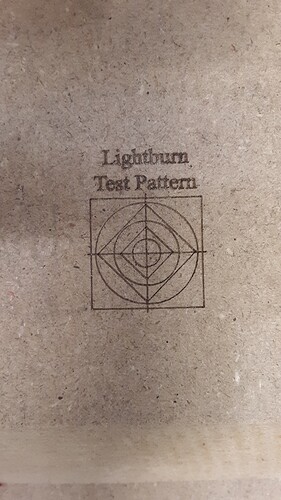

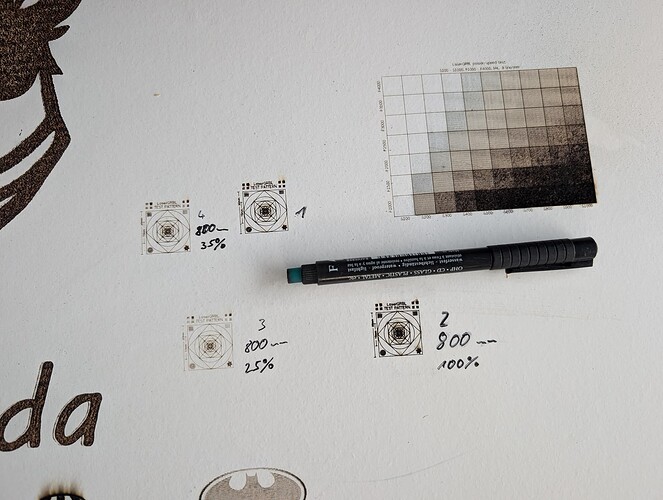

Yes, that test is small. Tiny fast moves are the most demanding for the machine. Those squiggles can be due to machine resonances as well as loose drive components. My S30 Pro did terrible on that test with black anodized aluminum, but consistently cuts to 0.58mm spacings between parts in Baltic Plywood. If you are not doing High precision work, do not worry about it. Scale the test up to 60-70mm and see how it turns out. If it is still bad, then attack mechanical adjustments.

Great! Just keep answering the questions and eventually it should make you happy.

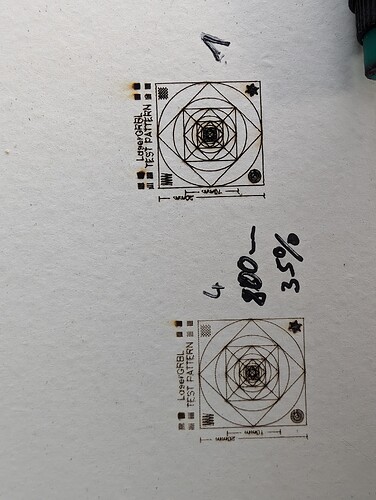

I tried it today with different settings

800 Millimeter per second

35%power

Also i indeed hat some mechanical issues i Had to ha glue stuck on the x Axis! ![]() It was only is small dot but exactly where the test pattern was

It was only is small dot but exactly where the test pattern was

do i push this or make in a few weeks a new post? else it will get closed after 30 days ![]()

im still stuck at the same point

Hello! Same problem.

I noticed the sent gcode is wrong.

G00 G40 G90 G17 G21 G54 Start with a queue

And the G54 does not like him. It gets stuck.

I guess lughtburn buttons also have macros. There may also be code in it that the machine does not like.

Only the G54 he doesn’t like. That’s what makes the machine die.

so do u have any idea how to fix it? ![]()

atleast we get something new now. thank you

Yes. G code backup, then open it, delete at the beginning the line where it is:

G00 G40 G21 G54 Because of G54

Then lightburn g code run, load the file, and go.

But I do it so that gcode save, I’ll open it with notepad, I delete the G54, And I run grbl.