Trying to draw the outline of a trophy shield shape at 600mms and with 20% power, the machine struggles after the 2nd turn and starts to mess up the shape. I noticed that this problem disappears when I set it at a lower speed of 100mms. Should this sort of thing be happening?

Faster than you ever need to run. This is the maximum speed this can (or can’t) run. It doesn’t sound like it’s capable of this speed from your description.

Without seeing/hearing it, it sounds like it’s missing steps, the magnetic fields are moving faster than the motors mechanics parts can respond.

If you’re exceeding 300 - 400mm/s I’m wondering what you’re doing…

Depending on what you’re doing, it’s likely it’s never actually attaining these speeds.

Besides the job will likely run slower even at these speeds.

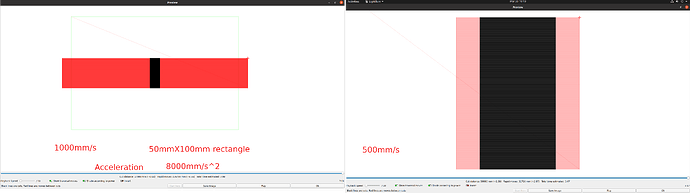

Both of these are 50x100mm rectangles. Left is at 1000mm/s right is 500mm/s. The slower 500mm/s completes in 3:47, the 1000mm/s completes in 7:08

The green box is actually the working area, since it’s being exceeded, the Ruida would generate a slop error.

Make sense?

![]()

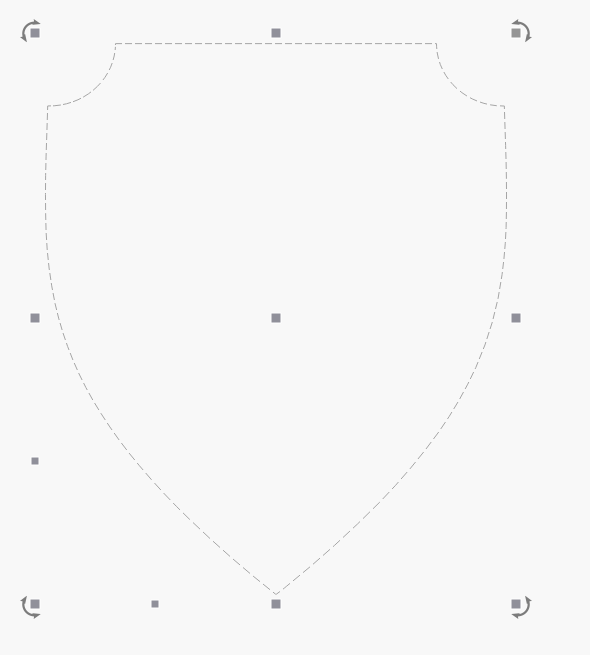

Total sense, thanks. So I should sometimes consider running certain engraving in a lower speed even if the machine should accept higher. It’s just odd that it made this error for this shape but it has never had a problem with others. Here is the shape in question. It was just the line, not a fill.

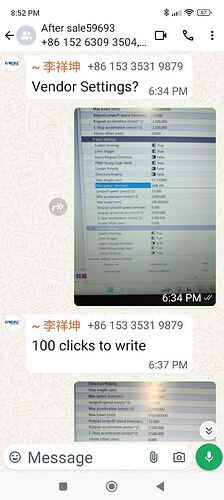

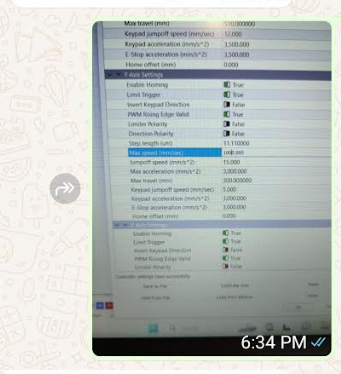

Hi I have the same laser, had the same type of issue from day one, no one could help, finally support at gweike cloud understood and got me to change the y max speed from 1000 to 100 this solved my issues, you can still engrave at high speeds on the x axis when burning images etc, but my machine does not seem to like anything faster than 100 on the y when framing marking shapes etc it gets all out of shape, I can only think it’s the weight of the gantry with the laser tube on it, even though there are two stepper motors on the y, that was the only thing that worked for me in the end, I guess it’s just a gweike cloud pro 55w thing. here is a screen shot from gweike

I don’t think you understand the scope of what they changed. You told it not to exceed 100mm/s in the Y direction.

This is the maximum speed limit on the Y axes under any circumstances. Any component of movement using the Y axes will be limited to 100mm/s.

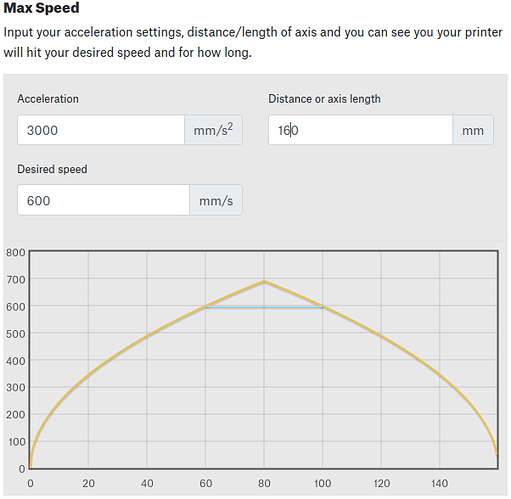

The values interact with the acceleration values. Here is a graph from one of the on-line calculators showing it will take 60mm to reach 600mm/s. Anywhere there are corners you aren’t going to make speed. Especially with the vertical parts as that part of movement is restricted to 100mm/s.

IMHO … I think their solution was ![]() ,

,

I don’t know of anyone here with this machine, whom we can ask about some of the maximum speeds set within the controller are really valid… Yours doesn’t sound right.

I think @BillieRuben has an OMTech Polar, similar machine, maybe she can post the X and Y maximum speed, start speed and acceleration values.

If maximum Y speed from the factory, was 1000mm/s, that’s pretty deluded in my estimation…

![]()

Hi Jack, you gave me a thumbs up reply on this issue on 7 February, so I don’t know anything about machine settings I just wanted to get the thing to work and this worked for me after months of frustration, whatever the correct settings are I don’t know, but since changing that setting at least I can now use the machine, It’s a pity the machine obviously was not set up right when I received it, as I really thought I had wasted my money.

This appears to be a pretty common practice with all of these machines. Mine wasn’t setup correctly and the rotary on the fiber also wasn’t setup properly… one from OMTech the other from Cloudray.

We’ll help you out if we can. You should be able to use a faster Y maximum speed than the one they set you up with. That was a dumb quick fix for them, sadly shows the competence level.

I was hoping that @BillieRuben would drop in and give us what she has for the Polar, a physically similar machine. Hoping these values will be closer to what you should have.

You can do this yourself, by increasing the acceleration in steps until it fails… then back off… this is the basic way to tune these up…

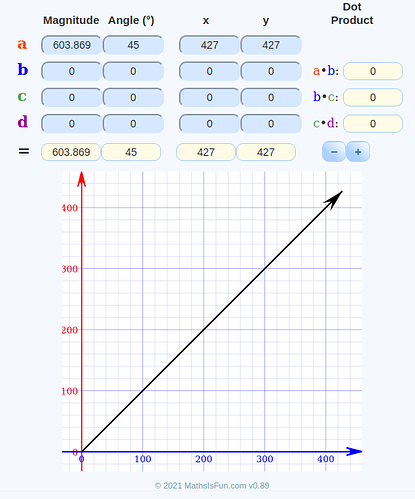

It’s also likely that the top speed of this is actually a 45 deg movement, meaning both axes don’t have to run 600mm/s to get a 600mm/s maximum speed … If both X and Y axes are moving at 427mm/s, the resultant speed vector (black) is 603.9mm/s …

There is no reason for you to move this fast anyway and may effect the results. There are other things occurring that can’t respond quick enough for these kinds of speeds.

![]()

Hi Jack, thanks I did already play with the Y speed , the best I could do was < 200 mm/sec

Unfortunately very small fonts don’t like anything higher than 100 mm/sec so at this stage I’ll just leave it there while it is at least usable.

I think the problem is acceleration, not maximum speed. They kind of go hand in hand… the acceleration is based on the amount of mass it’s moving… More mass more acceleration… however the limit is the motors power ability.

Lower acceleration takes more time/distance to achieve speed, but requires less powerful motors.

How big is the art you are using? If it’s very small it can’t reach the specified 200mm/s.

If your Y can’t exceed 200mm/s I’d ask for a replacement because something else is wrong. This is slower than most of the diode lasers you can get today. Some will run 900mm/s…

What is the Y acceleration value?

![]()

Maybe @Johnjohn can find someone with one of these … I really question these values…

Since both the X and Y axes appear to have a maximum speed when you got it of 1000mm/s, I don’t think much was done to set it up…

I’d like to hear from someone else that can read the settings off their Gweike.

![]()

Jack the original max acceleration for the Y was 3000 mm/sec they are the only 2 settings I changed

I remembered I slowed it to 1000

I actually have the Gewike, not the Polar!

I can engrave at 300mm/sec on the x pretty easily.

I haven’t pushed the limits of Y though, haven’t found a need yet. But I did note that my table shook like crazy when I did do some, so I agree that it must be slinging a lot more weight.

I haven’t changed any of my default limits.

It still sounds like something mechanical isn’t right on your machine, it’s a shame they didn’t help you solve the root of the issue.

This page may be of use:

thanks for the reply BillieRuben

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.