I lasered a small farm car, but putting it together is difficult, it fits very badly, does anyone know how I can adjust that in lightburn???

drawing is made in 3mm thickness and plywood is 3.2mm

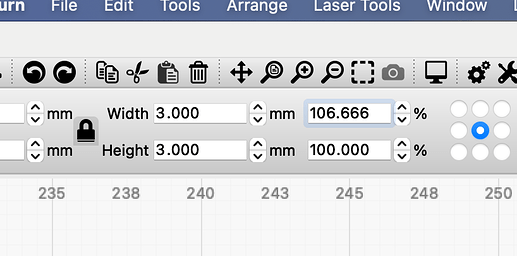

Highlight your drawing and type 106,666 in the percentage field and press enter. (Aspect ratio must be locked)

Bern.dk - Thanks! I spent 3 hrs last night trying to adjust a file with similar issues. Been using LB for a little over a month and am learning something new each day , thanks to folks like you sharing their wisdom.

Dean M

This is the way it works, I have also received a lot of input from here. I am glad that you have found a solution that you can use.

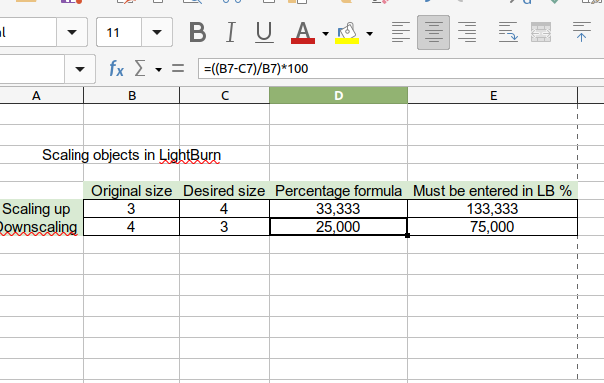

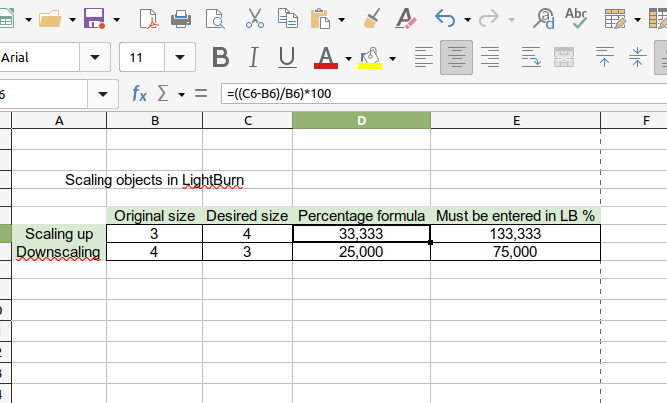

Because I forget this kind of thing when I don’t use it regularly, just like Ohm’s law, I made a little formula sheet. I then always measure my material thickness and use that percentage formula to adjust my drawings, very simple but super effective.

thanks for answer

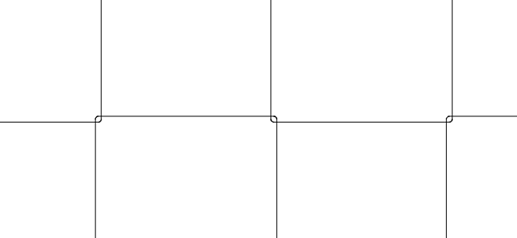

One more quick question - when making a box do you cut one piece with a kerf and the other without? I figured if I put the same kerf on each, they null themselves out.

Would you care to share that sheet here? I have very bad memory issues and it would be very helpful to have a tool like this.

The hole you cut out obviously doesn’t fit. Kerf is divided into two separate shapes. You need to cut a separate circle with the nominal diameter, the kerf setting takes care of the rest. And it is also important that the shape must be closed, otherwise it will not work.

Of course, I have saved the file in open office format, which should be openable in all spreadsheet programs.

(txt must be replaced with ods)

If you have problems with that, let me know and I’ll find another solution.

Procentregning LightBurn.txt (10.8 KB)

Thank you, that will be a big help as I am wanting to make a lot of boxes.

You can try playing a little with the kerf settings and see how it looks in preview. It is actually quite interesting and clear.

In my example, it is square with 40mm and 0.5mm kerfsetting to be able to see it.

I can’t seem to get it to open right. Would it be to much trouble to take a screen shot and just send that? Unless you know of something easier?

I once lasered a 20x20mm block, and found out that X was good, but Y was 0.5 mm smaller, so 1.95 mm, so I calibrated it, tomorrow I’ll see if it is better now.

Sorry you can’t open it, you changed the extension to “.ods”?

Anyway, here’s the Screen dump with both formulas.

Thank you for that. I really do appreciate it.

The file for the formula opens if you have open office…Thanks for it…

how did you get that 106,666

could you explain how to do that??

I now have 3mm MDF and would like the drawing a bit bigger, because a lot doesn’t fit now

do you have a movie showing how to do it???

.look for question

6.6666% is what is needed to get to 3.2mm from 3mm.

100 as a starting point from the original plus the 6.6…% must then be entered in LightBurn.

You can use the formula or the small spreadsheet to enter any material thickness and the desired value.

If it is “only” the fit itself that needs to be fine-tuned, kerf is used for that. (I use 0.05-0.075 as a standard for my finger joints, I like them a bit tight.

what is KERF?? the translator also returns KERF, but I don’t know what that is.