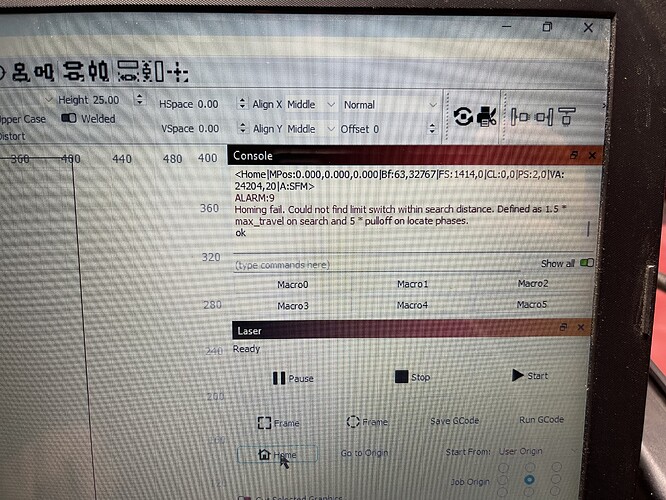

My lm3 has never homed properly but now I cannot get it to go to origin either. Most of what I make is circular so I never use absolute coordinates. Now I can’t get it to work at all and I am not sure why. Lightburn version is 1.4.05.

Don’t use user origin. Use “current position”. Then you can manually position the laser anywhere you want and just start.

You might need to clear and set a new user origin if you really need to use one (though I don’t see why one should use a user origin).

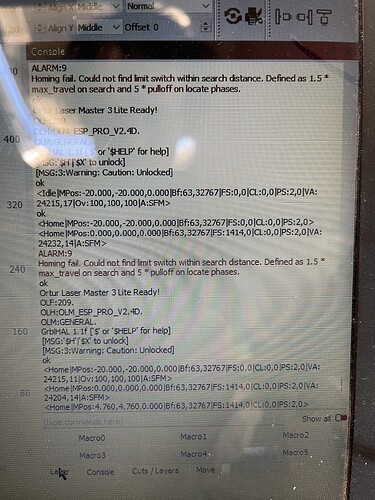

The error message shows that the laser did not recognize the limit switches. Do you have some? Did you check if they work electrically?

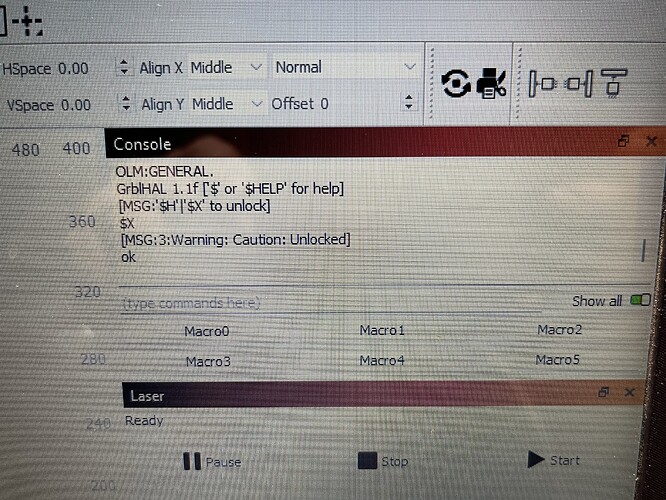

The Lm3 has built in homing. I don’t see visible switches. There are just screws where it is supposed to stop. I always use “user origin” because everything I make is round and has to he based off of the center if my work. Now if I try to frame it has a warning that says, Caution: unlocked. I tried restoring to factory. I entered the command $22=1 and $141=1,000 to switch back from rotary to flat.

I would definitly start by resetting firmware to defaults and make sure you are on 210 version

$RST=* in console

Once done, and because USB carries voltage enough to power motherboard, i would unplug USB

JUST on power adapter, power on machine and make sure it trys to home. If so, does it home correctly or not?

Is quite possible you are not getting 24v

It does not home correctly without the computer attached. It will try to go home and then after 5 attempts it beeps. The console window just says homing error. I updated firmware just a few moments ago and restored lightburn back to default. Registered my lm3 again and it still does it. Now though it does fire. Earlier it kept saying “cut out of bounds, try anyway?” I set it to current position and it started working at least.

You have hardware issues on hand

So we need to fix things upstream of lightburn

1- go to COnsole, and type $RST=*

press enter

Then

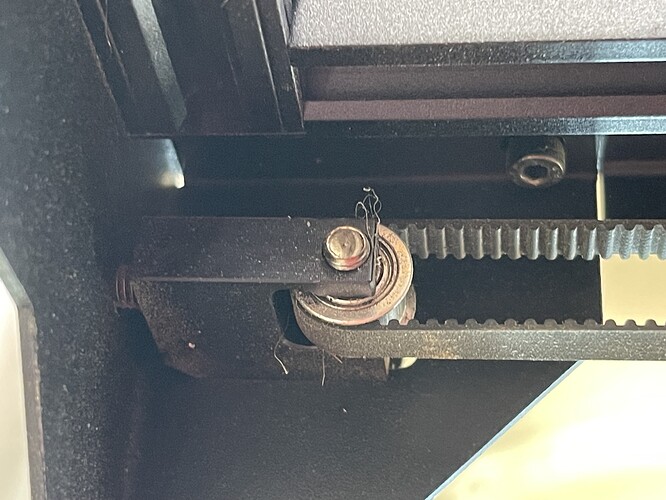

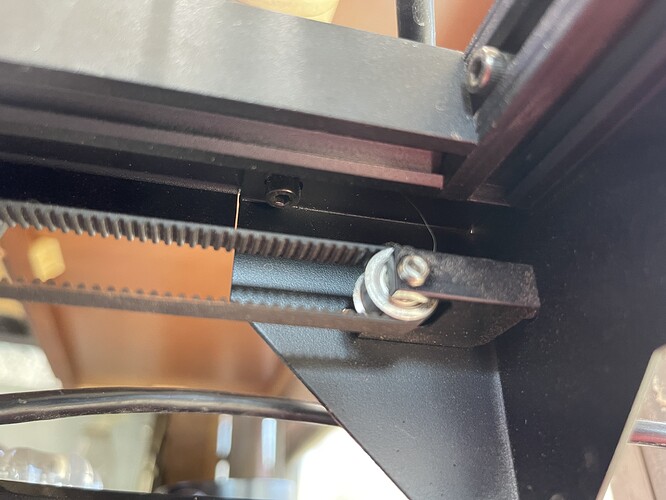

a) Take 2 pictures of your belt tensioners on the Y axis. upclose

b) if possible, move head to center. Power of machine and record video the homing attempt. maybe upload to youtube and post here

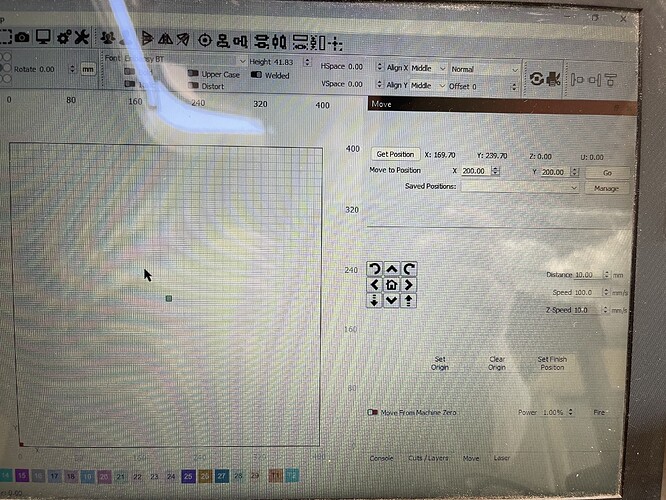

When I tell the laser to go to position X200 and Y200 it is off. Says the laser is at X169 and Y239.

Here is the video of the homing fail. And directing it to X200 Y200. https://youtube.com/shorts/8T9W1E0SsMc?si=HYwcnFPtHXKOFU1c

ok so seems to me a few things are out of order

a) move your x axis to the very back, make sure both ends (left and right) are touching the screws at the SAME time. If they are not your x is out of square with frame which might explain the problem of homing.

If they are not square you will need to loosen 1 side of your shaft couplers, press frame to the end stops, then tighten it again

b) your belts, pluke them as a guitar string, they should “sound” the same, i feel they could be slightly more tensions

c) everything upstream of a failed homing will give you troubles, so you need to confirm and make sure homing works and works consistently

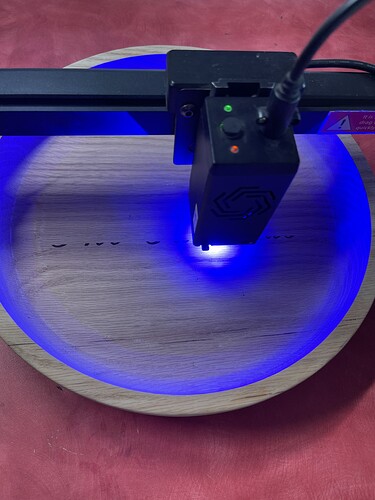

It was not completely square so I adjusted that. I sent it to home but forgot I had my rotary attached. I had started a small bowl earlier. The X motor is the one that makes the five attempts. The Y was attached to the rotary and it still made the same noise. So I reattached the Y stepper and it is still doing it. But if I just stick with current position and tediously frame it I can still engrave.

peculiar, it really shouldn’t do it.

Again assuming your firmware is on defaults

It has to be hardware related, not software s homing is fully controlled by firmware of the machine.

Belt tension being equal is really important on the machine. But you could isolate the homing by axis by plugging only X, hen only Y and see which axis miss behaves

It is the X axis. I just unplugged the Y. I made sure the coupler screws were tight. Checked the clips and made sure I have the correct power supply.

The error is understandable

Try this. if you think you can might get tricly

Using your YRR extension cable, can you see if you can plug your Y motor cable to your X motor

then do the oposite, X cable to Y motor

Idea here is to see if the noise/error comes from the controller itself - which means as you swap cables the issue should move to the motor you plug to, regardless of which it is

or if its mechanical. if the issue persists on X axis regardless of which “controller” is moving it then is for sure something in the frame.

In this case i would inspect carefully the X motor sproket (attached to the motor shaft) they tend to get loose

And on the oposite side the bearing where the belt rolls and where is tensioned.

Of course, while having X unplugged you can use your hand to move the axis to see if you feel something odd going on

You’re a wizard. That actually homed correctly but on the right side. It did not make the cranky noise and the laser says the position is 0 instead of -20. So it may be the connection.

mmmmmmm now thats not good

Because it means is the sensor on the X axis thats not working right

Try now X on Y motor (if you can)

Does error move to Y motor homing?

Same thing. It went to the right with no issue. I want to see if I can set homing to the right and see if it does it on the left.

hang on.

So Y on X motor will move it to the right (because is inverted) and it stops at the end

but X on the Y motor should move gantry to the back, does it stop too

SEems to me if both motor drivers are moving it correct the problem is mechanical and is very localized when gantry reaches laser head to the LEFT side of frame, so you should be able to feel if there is any problem by moving it by hand

I reset lightburn to default and tried setting homing to the right. Still attempts to home on the left and has position at -20. I got it to fire though. It’ll make stuff and since everything I make is round I can work with it. It actually seems to burn stronger. If that makes any sense at all. This is my first laser.

If you reset to defaults maybe you can also check your Smax Value on Edit → Device settings is 1000

if so, you are golden!

And yes if you are doing mostly rounds, homing is not very important

I would still get in touch with ortur when you have some down time and try to see whats what

support@ortur3d.com is their support email

. . . Ich habe den Befehl $22=1 und $141=1.000 eingegeben, um von rotierend auf flach umzuschalten. . .

achtung, lightburn möchte einen punkt als dezimaltrenner, auf einen tausender trenner reagiert er mit irgendwas aber nicht mit der gewünschten eingabe.

vielleicht ist das schon ein fehler?