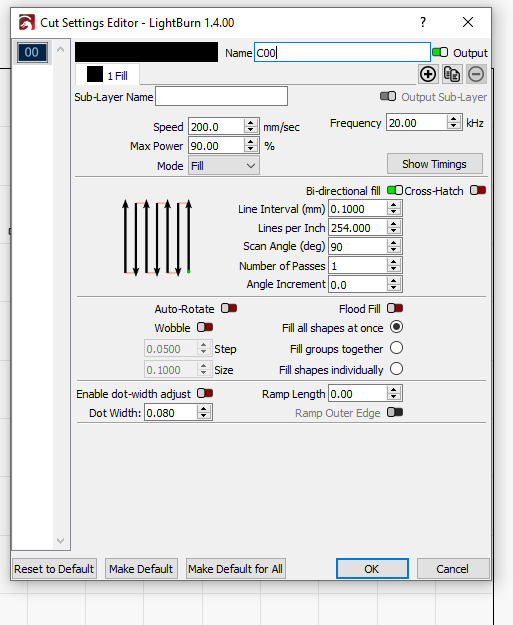

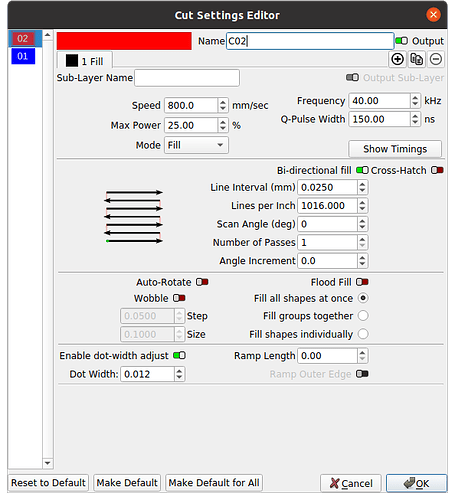

I use a dpi of 0.025mm or 0.0254mm, I notice you use 0.10mm…

The dpi/lpi is critcal for most laser jobs… I suggest you watch the Laser Everything video on photo engraving… even if you are not using it for photos the education of how to select the proper dpi/lpi will be invaluable throughout your laser journey… The process works for any laser with any material…

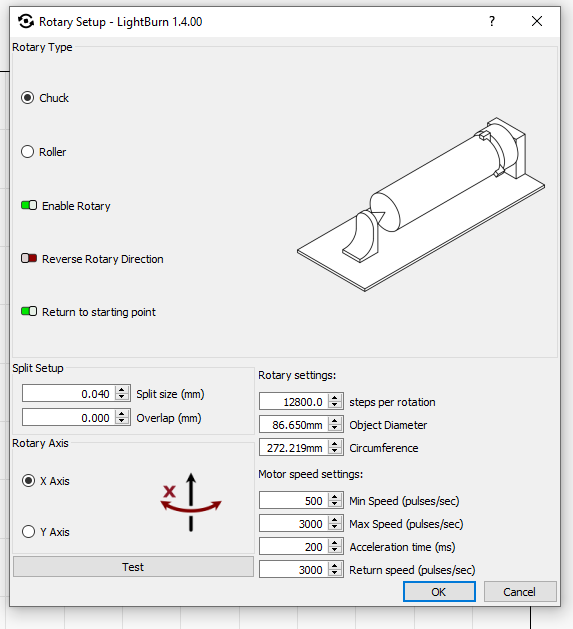

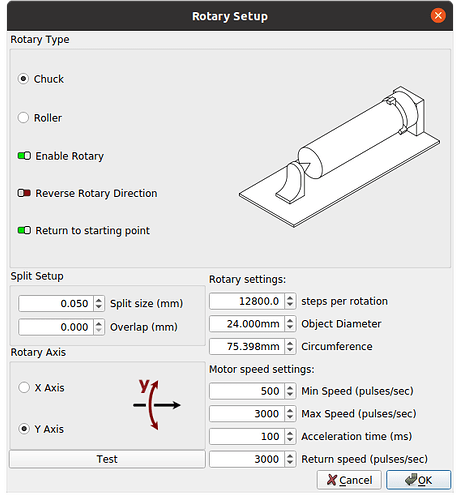

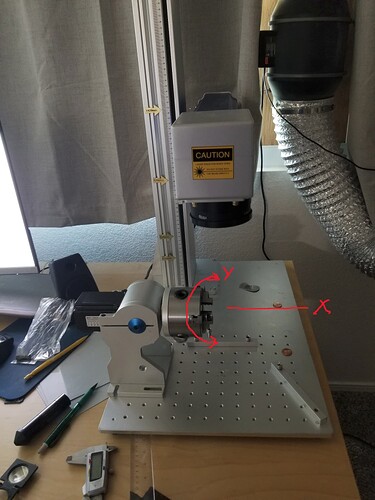

I also noticed that you have it set for the X axes and you turn it 90 in the layer for the scan angle… to correct for the actual alignment of the rotary.

If the rotary has the mug where the tall portion is going left to right across the X axes then the rotary is rotating around the Y axes… You have the X selected for the rotary…

It might be a moot point, as changing the scan angle to 90 corrects an incorrect axes setting, this kind of obfuscates what you are doing for us trying to help you…

Make sense?

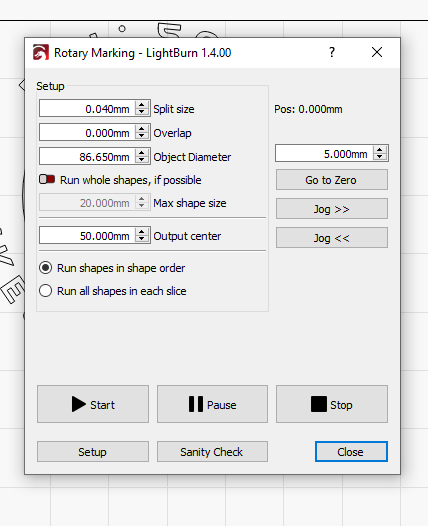

The other selection I noticed is the split size.

Usually the split size is related to how far your lens stays in focus over the curvature…

In theory it’s a multiple of the dpi… the smaller it is the more time it will take to do the job…

For example if you had a 55g drum, you could use a much larger split size as the lens would probably cover the small amount of curvature in a large distance… the larger the split size the quicker the job…

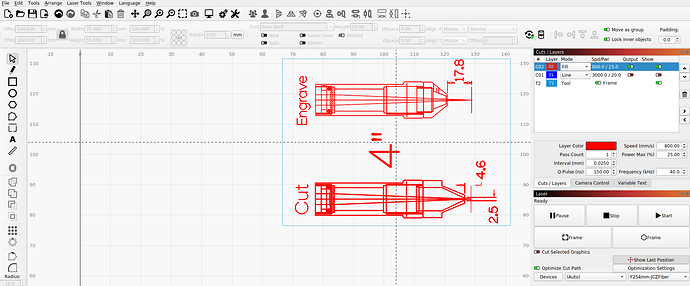

This is my rotary settings for a lens tube and it’s cut/layer settings… same idea…

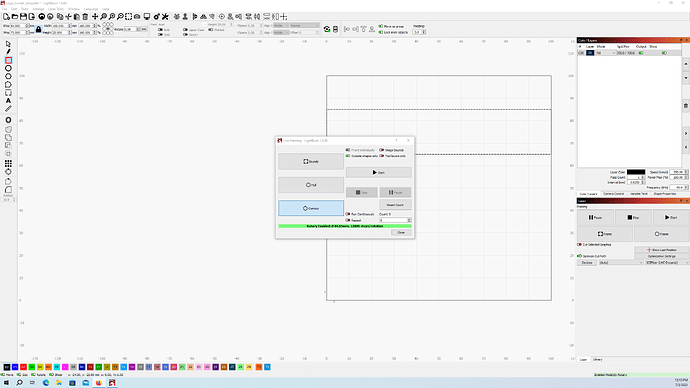

Art, rotary and layer… I have an M60 JPT M7 MOPA … notice that Laser Tools is on the tool bar.

The rotational direction of the mug (tube) is in the Y direction…

I don’t know if either of these is your problem, but it’s a start… if the setup was more consistent with what many of us use, it might be easier to diagnose your issue.

Are you actually engraving the stainless or just annealing it to leave a black mark?

This is annealed/oxidized, depending on what you call the process… it’s smooth to the touch…

What lens/source/power is your machine?

Does any of this make sense?

Usually when I get the browns with stainless, it’s running too much power, low frequency and/or a long q-pulse.

Most of us read your information or profile to determine what kind of machine you have… it might be of benefit to you to add fiber to the type of machine you have… that would tip people off you don’t have a grbl based machine…

Probably why you got a response from @Bikemike related to grbl machines… we all have fell into that trap… In all references… I believe fiber machines are pumped by solid state (ss) diode dpssl lasers, so they are also diode lasers…

You can read a users profile by clicking on the users name on the post…

Good luck