Should be doesn’t really cut it… Especially with short lenses. I don’t use those and have them turned off… I have a proper focal measurement, but always use a test piece to ensure focus…

I have focus stickers and approximate focus values on the column…

The shorter the lens the more critical the focus… Doesn’t look like it’s a problem for you… the focus on a F100 is very small…

Whatever works for you is probably the best way…

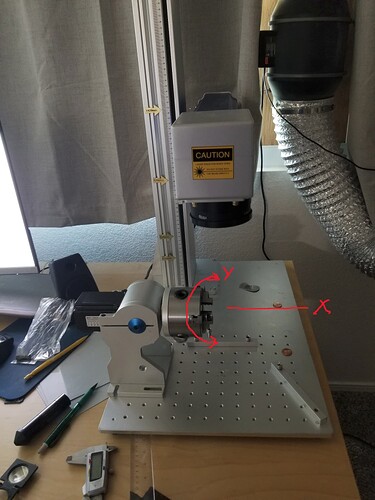

Looking at yours, it appears the front is to the right…?

I think you have it swapped, the 90 Deg scan angle corrects for the wrong axes selection in the gui setup… the scan angle should be 0 for these rotaries…

You can adjust the frequency lower than 60kHz… the lower the frequency the longer the pulse width as a general rule. The reason is that the fiber needs to be pumped up by the diodes before it lases. The faster (higher) the frequency the shorter the time to pump up the fiber for lasing.

The JPT manual on mine states the most power occurs at 40kHz but it will go up to 4000kHz…

Cylinder correction is for laying something like a flask on a flat surface…

Are you sure you have the diameter correct?

If this is incorrect, the Y image will be the incorrect size… sounds like that’s what’s happening…

Good luck

![]()