A friend got himself a diode laser as a Christmas present and I’m trying to help him get started with the machine and LightBurn.

The machine is equipped with limit switches. On both x and y, there are additional holes for hardstops, but either not fitted or functional. To me it looks like the gantry itself is built for a much smaller (5 Watt) laser. Is there anyone with the same machine who can inform me if they have moved their “hard stops” or only run on the electric stops?

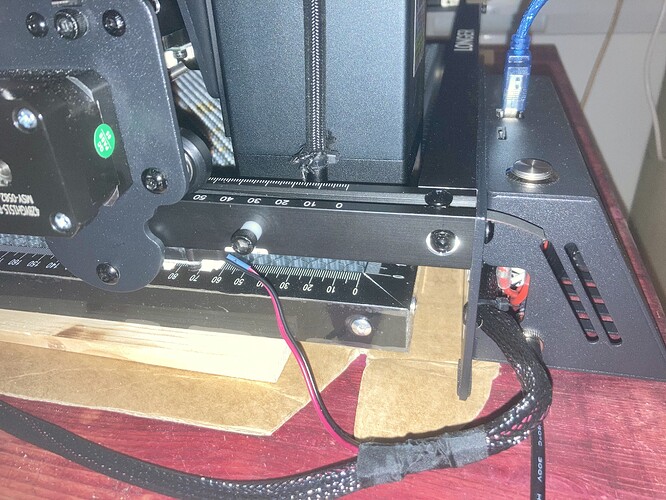

If that’s a picture of your friends machine I do see the hard stop. Its the little bolt washer just above the end of the wire sticking out. You dont want to remove these. What i dont see is the cable connected to the Y axis limit switch. Your machine should first hit the limit switch before it ever hits the hard stop on both X and Y. But you need the hard stop there in case the limit ever fails

Thanks for the answer. The physical end stop in picture (machine screw with nylon roll) can never reach the end stop that is over 35mm distance from Limitswitsh to the screw. On the second axis, the “physical end stop” is not mounted at all.

There is not so much power in the movement of this machine, but yet the axes should be secured in the case of a malfunction. Limitswitsches should not act as physical end stops. (In my opinion)

Unfortunately, you cannot put the limit switch after the end stop. The end stop is for “when nothing else works” On my machine, the frame is the end stops.

Please look for the quick start guide, there it is very good described for mounting the limit switches.

Exactly what I mean. But with a distance of approx. 35mm - after the switch the “physical” end stop is meaningless on this machine. And on the X axis there is no stop screw at all. In the event of an error in the coordinate system or operation, the axes will crush a flimsy electrical contact.

I have built a few machines myself, and placement of the end stops is not the problem. The machine does not fit the instruction or vice versa… this has been seen before with machines from our Asian friends… I just wanted to confirm that it is only this one machine that they have sent the wrong frame for this laser.

If it was my machine I would have drilled new holes and fitted the securing bolts correctly, without arguing. But my friend doesn’t know yet whether he should complain about the machine or not.

Okay, I will bite… Complain to who???

can it be, the fram is 5W and they put a 20W module on as a “upgrade” version but they did not account for the extra thickness of the 20W? sounds and looks like it (seen it happen before on other brands too)

Yes, that’s what I am assuming and also wrote at first. The “problem” for my friend is that he has bought and paid a 20 watt machine.

I just change the mechanical end stops to fit.

Does the red/black wires go to a switch under the rails… to the left of the hard stop?

![]()

Yes, they are connected to the electrical limit switch and both limit switches are working properly.

The picture clearly shows that there are approx. 35 mm distance from the mechanical stop while the electrical switch is activated, it is this distance and the missing stop screw on the x axis that I “criticize”.

this was probably a batch oversight and will more than likely be fixed on next batch

Happens… ask me how i know! hahaha

Thank you to everyone who was part of this little discussion.

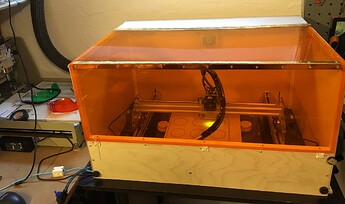

My friend has recycled my old encapsulation from my 5 watt diode laser and I fix the rest with the machine setup / endstops … The first test we have run and the result is promising. Now my friend has to study Lightburn and start from the beginning with the laser - just as all of us have done.

Original for the Eleksmaker 5 Watts

The new recycled version for the Longer machine. The control panel which is part of the frame construction has been moved out of the box and replaced by a 4mm acrylic copy of the stand plate.

PS. I couldn’t really convince him it’s a bad idea to use the kitchen hood as extraction … now, after the first tests the wife “thrown him out” (only out of the kitchen ![]() )

)

We have moved the machine to my workshop, here it is nice warm and the “infrastuct” with extraction and computer ect. fits (me) better.

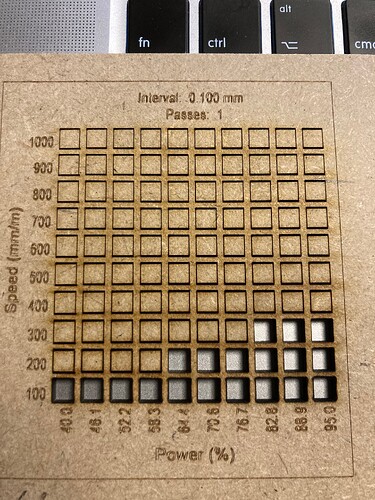

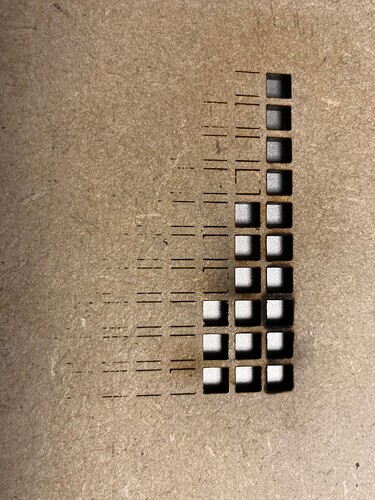

We have done the first serious tests today with MDF and I am actually impressed. With the paltry 20 Watts, the diodes cut fine through 3mm MDF with approx. 250mm/min and 85% power. Respect!

What I’m not so impressed with is the laser dot. Roughly speaking, it is twice as long as it is wide, and this can also be clearly seen in the tests. It’s really a bit of a shame. The machine loses about a third to a half of its capacity with this “beam design”.

I have played a bit with the machine’s setup and thank God saved the initial settings. Turns out I was too quick with some changes with a result I couldn’t just reset…

We still get sporadic messages about hardstop alarms when homing which I can’t find the reason for, and the hom is not 0:0 either but 2.4 and 2.6 or something like that…But it’s progressing.

This is pretty much standard. and if you only have a 1:2 racio thats great

Collimating multiple 5W diodes into a dot squareish is tough. only a couple modules i seen so far doing it.

Again though more optics to make it better = more loss on power = more heat

So is always a compromise. What you would need to stablish is … the speed of cut is defined by the worse cutting side, not by the best.

Absolutely the same opinion here.

I’ve also had the same problem with my old 5.5 watt diode laser but probably forgot a little …

I felt that with all the mirrors in the new 20 … 40 watt diode lases that they could be “controlled-merged” a little better …

It’s still a useful tool ![]()

the cost of doing this would be higher than the module cost itself

So yes is a commodity module, not a optical master craft (which no one would buy at its cost price! LOL)

An entirely different question I was thinking of today … In the such a laser there are 4 diodes in some 8 diodes … Will they all hold to high load for a long time?

yes, specially as most times they are even over drivven

Also only makes sense that way as its easier to control electronically

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.