so if you want to connect you makerbase DLC32 v2.1 to your laser power supply . you solder the ttl(N on laser power supply) to the left leg of the laser connecter mosfet make sure u use the left leg . then take the L connector and connect it to the SCL pin (for I2C) then you are done no need for external control using variable resistor .

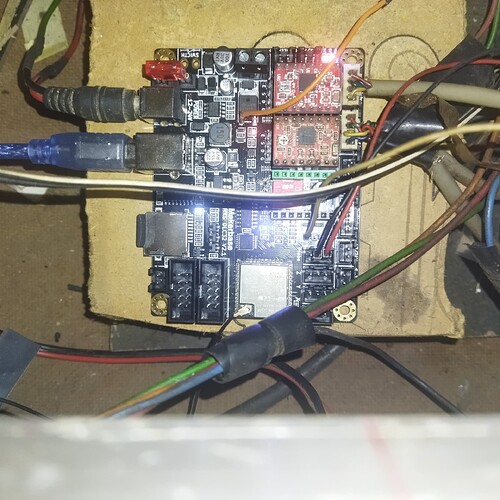

have attached my connections picture. now can use lightburn to control your laser power

in short

ttl output of the DLC32 → IN of the lps?

Along with SCL → L of the lps?