Greetings!

We are trying to move away from EZCad and test working with Lightburn, but we cannot create the same workspace as in EZCad.

At the moment, we have a working solution in Lightburn that can perform marking in a static area (without moving the guide; the laser is mounted on the guide, the table is fixed).

All these components came to us as ready-made equipment with a Raycus 30W laser + control board + work table.

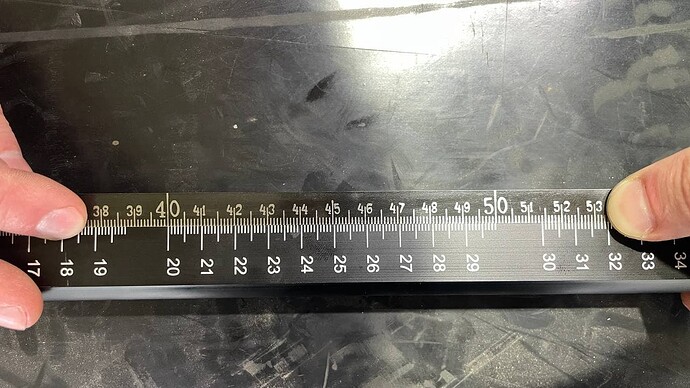

We mark full length rulers up to 4.5 meters long. In our case, a linear actuator with a length of 4.5 meters is used. It works fine with EZCad in operation mode, but as everyone knows, this software is awful: it freezes during the marking process and hangs on large projects.

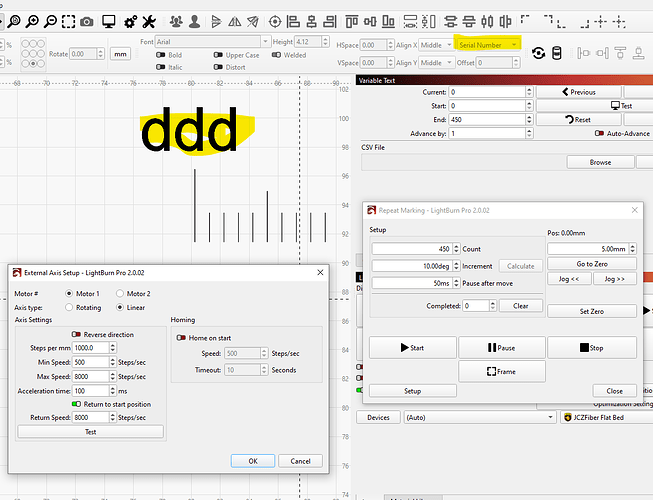

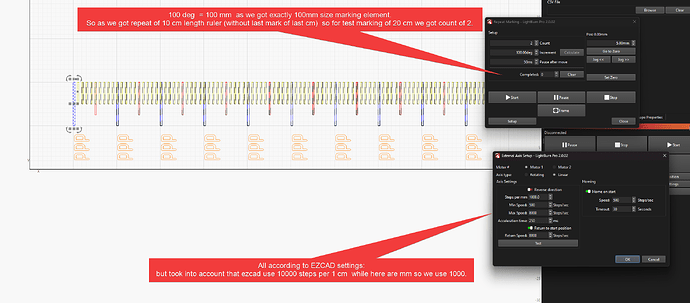

To control the laser movement, we used the SplitMark2 plugin in EZCad.

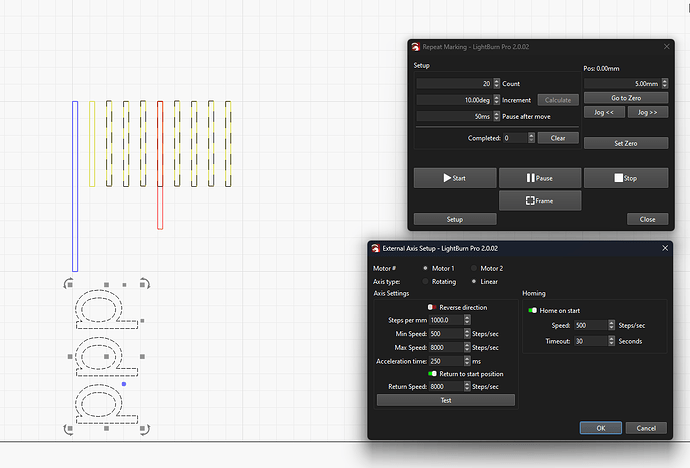

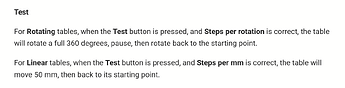

We tried using the Rotary (Roller/Chuck) movement mode for control, but we ran into a problem — we hit the limits of the maximum parameter values.

Since there is no identical parameter set between Lightburn and EZCad, we recalculated the parameters mathematically and entered the values. The mechanism started working, but only within 1 meter, while we need 4.5 meters. We cannot set values larger than the current ones…

Perhaps we chose the wrong working mode in Lightburn, or maybe there is a way to increase these values?

I would be very grateful if someone could advise…

We would really like to use Lightburn to solve our tasks, compared to EZCad it’s like “heaven and earth”!

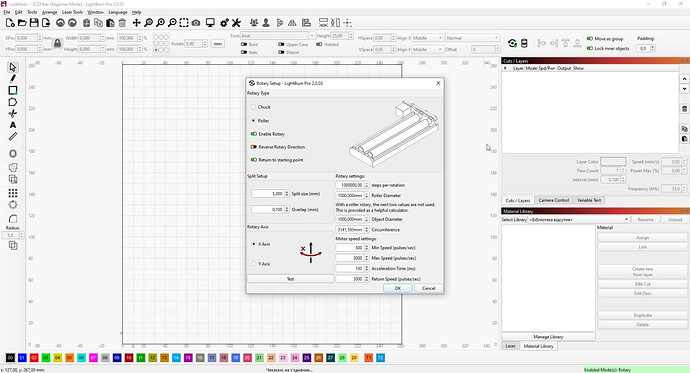

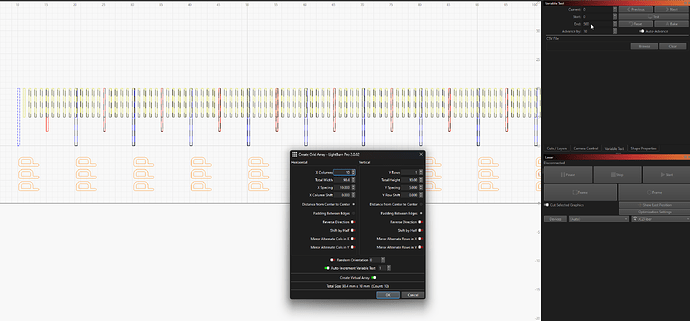

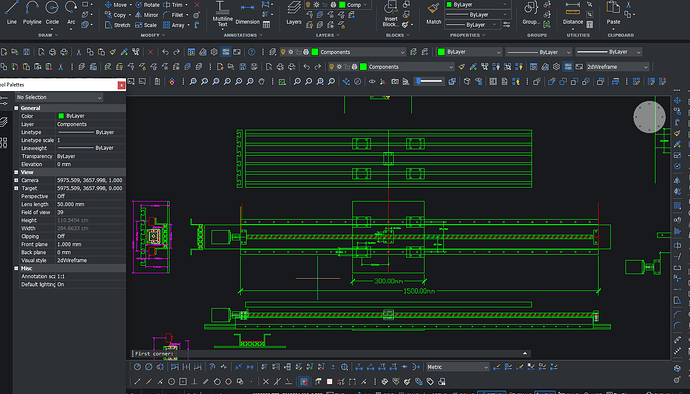

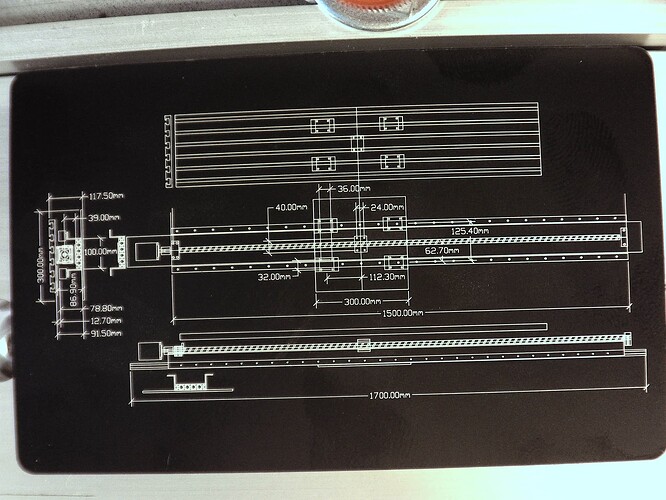

Here is a visualization of the working area:

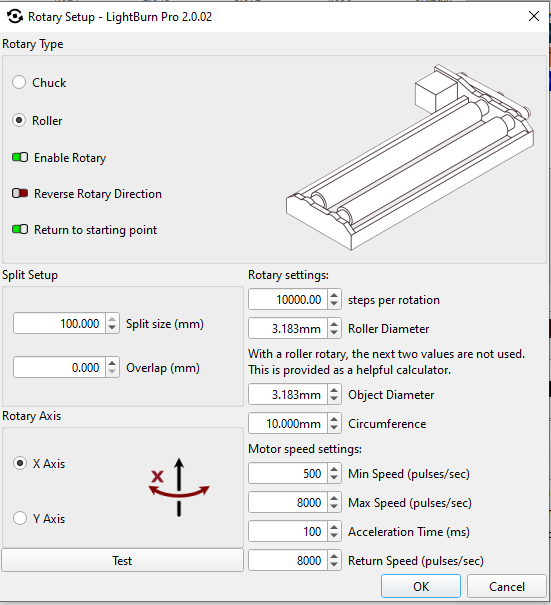

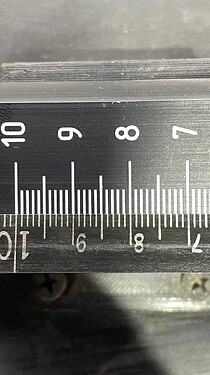

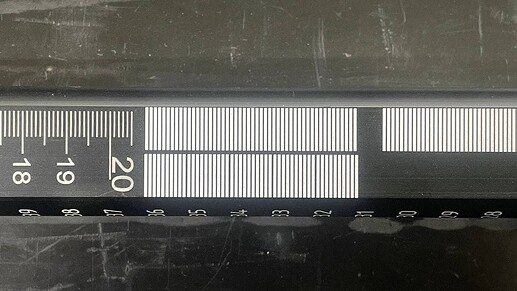

Ezcad settings:

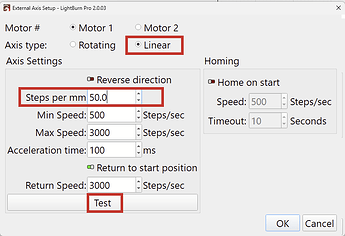

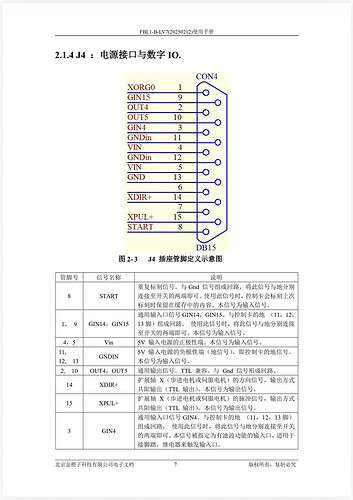

Rotary settings in LB: