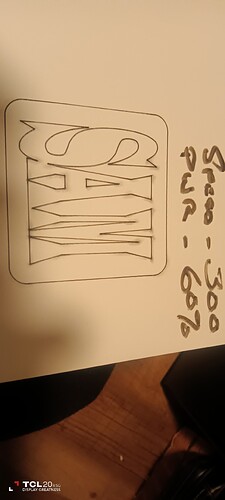

Tried another cut set the speed at 300 and the power at 60% on a 2mm acrylic

When you did the mirror alignment did you adjust mirror 3 to make sure it’s coming out of the nozzle in the center?

Hi Jeff. The answer is no I did not adjust mirror 3 to make sure its coming out of the middle dead Centre, I have just ordered some new gold mirrors as I noticed the old ones had a slight burn, so maybe this is the problem?

Part of the requirement is clean and aligned optics.

Sometimes you can just clean them off.

![]()

Hi Jack.

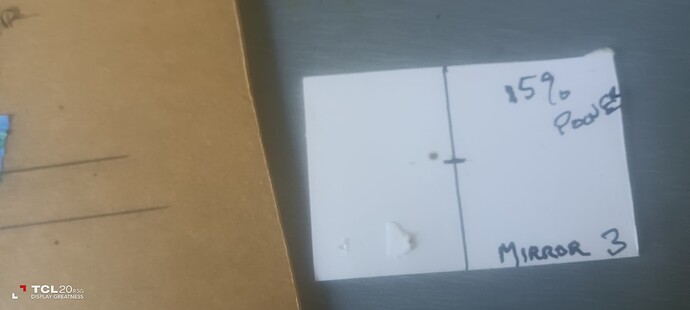

ordered new mirrors should be here shortly, did some more tests this morning, Brisbane time. here are the pics at 15% power on mirror 3 the white card is the last shot and looks better but not there yet.

Yea… terrible way to teach it… must work for someone.

Most of us do a ramp test. Prop the material up at one end so the focus changes as it makes a line. He’s effectively doing something similar but digital, moving the material across the range by doing a line at each 5mm change in Z.

Don’t say this around the airport…

I don’t know what I’m looking at in the photos… there is no indication of up center of mirror or?

I think it would be nice if @JohnJohn could split this, at the proper place, and end this thread. It’s very off topic and is so long it’s painful to look back at what’s been covered here…

![]()

Bon Giorno Jack,

sorry but i never thought about that you are right, (Airport) haha

Do you have any comments about this last pic, I will try the Ramp Test today and come back to you. Thank you…

I don’t know what I’m looking at… I’m sure you understand, but I’m clueless

![]()

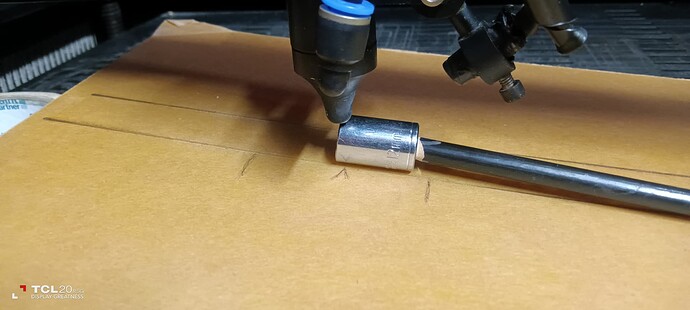

If that’s where it’s in focus, then the diameter of the socket is correct for that lens.

![]()

9mm is the thickness of the socket, i will try that just waiting on the new lens, should come today

Good idea. Done. Have split when the subject started changing to mirror alignment.

Thanks

![]()

Hello Jack/ Nicholas

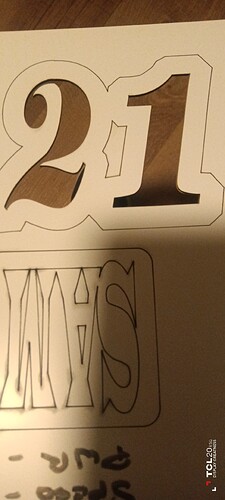

Still playing with trying to get a cut through on 3 mm acrylic.

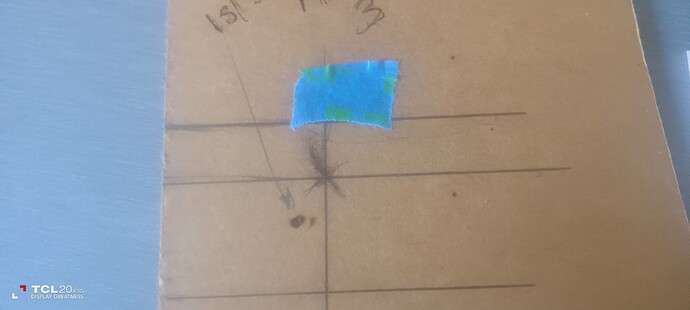

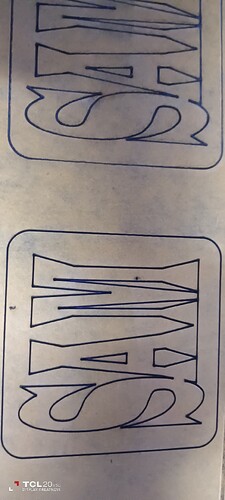

ran a new ramp test again to see if i missed anything, the result came out exactly the same see pics set speed at 40 and power at 50 only a fine line.

Tried a cut this morning from 5 speed to 25 speed and power at 40% through to 85 % line improved but still not cut through

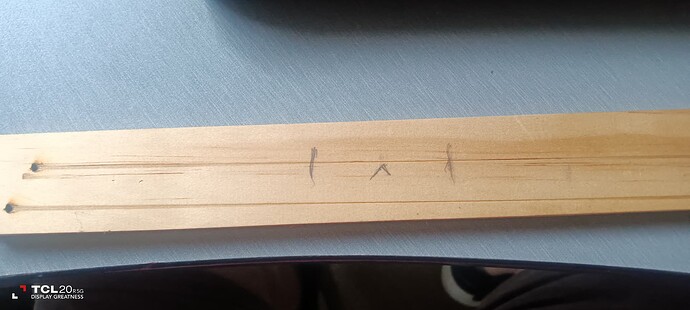

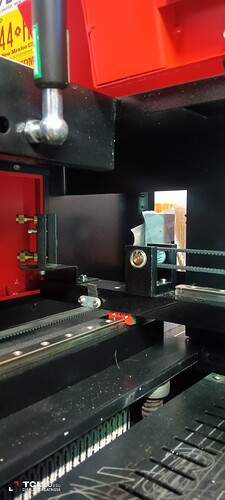

Have done alignment, but must be missing something with my allignment how it should be. first mirror hole centre, see pic second mirror close but not perfect, (no pics) hole down through centre of laser looks to be centre, will replace mirrors with new ones and do alignment test again, Help me Guys what am I missing here… Ramp test Pic

I’m still thinking your tube has an issue…

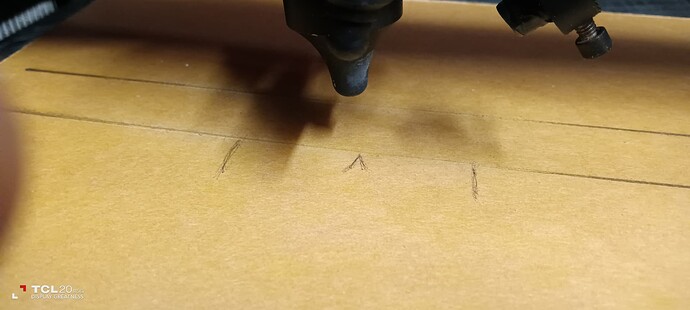

There should be a power distribution from the edge to dark in the center. This isn’t looking like that.

The center is not touched…

Can you do a burn at m1, very light so I can see the power distribution of your tube…?

![]()

![]()

Specifically, what is the result with 3mm acrylic at feed speed 18mm/s and power 85%? And if you run it at 18mm/s at 100% power is it any better?

Have you cleaned the focus lens yet? This demonstration is quite good:

Cleaning your Thunder Laser Focus Lens and Mirrors -

Computer Creationz

just received new lens will put in place and come back to you tomorrow, havent tried 100% yet will try your thoughts and let you know