Noise still on Y or moves to X?

noise on Y

Did you check the mechanics as per @misken link?

Are laser guides and rollers clean?

.

.

- Remove both Y belts and run a job to check noise of both Y motors.

- Y belt dos not seem very tight and seems a little twisted.

- Check alignment with the toothed gear wheels.

.

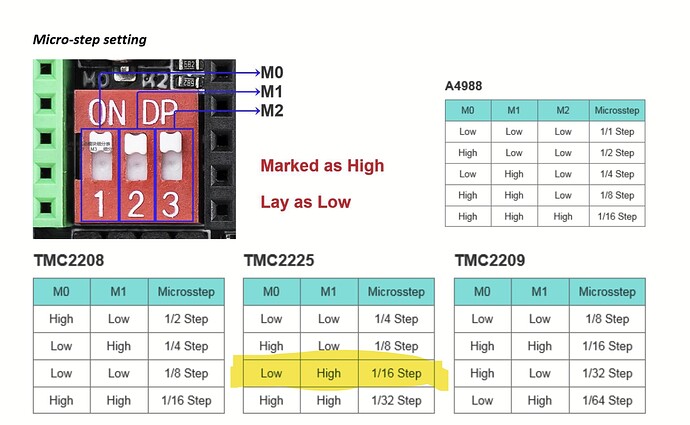

Motor seems ok then. Do you feel comfortable to lower current of the stepper driver a bit if its getting hot as per @Aaron.F link also check micro-stepping?

i checked everything

all is clean

i noticed that while running test ,cutting or engraving,the Y motors about 4-5 minutes of starting ,stops for 1 second as if it catches something then runs for about another 4-5 minutes and does the same thing

You have to align and tight at least the left Y belt. But before that remove both Y belts and run the job. Post results.

.

New firmware here (although I believe the laser have mechanical issues):

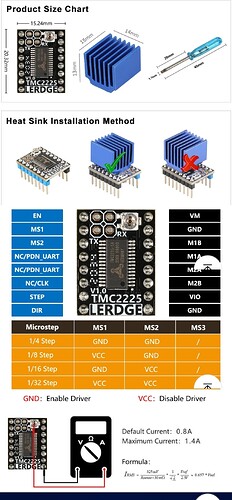

i dont know how to do the calculation for Vref…driver resistor is R110…motor DC 2,5V 1,5A…please help me for the result…i have voltmeter…thanks

i dont know how to do te Vref calculation …driver resistor is R110…motor DC 2,5V 1A…please help me…i have voltmeter…thanks

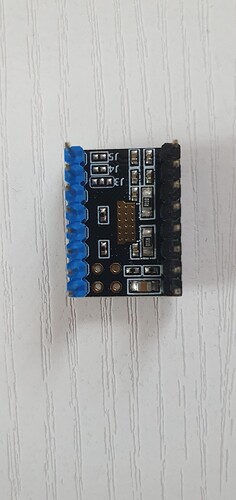

Are you using the A4988 Step sticks?

They look like this:

Then, the formula is as follows:

VREF = I x 8 x Rsense

I is the motor current. let’s take 0.9 A to be save.

→ VREF = 0.9 A * 8 * 0.11 Ohm = 0.792 V

Please, take note of the Voltage as it is now for information.

i dont know if i.m doing it right

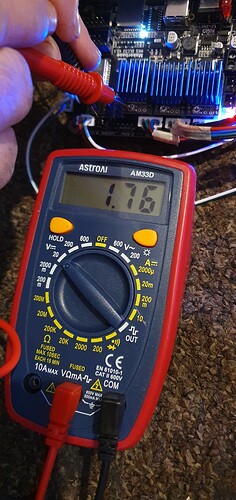

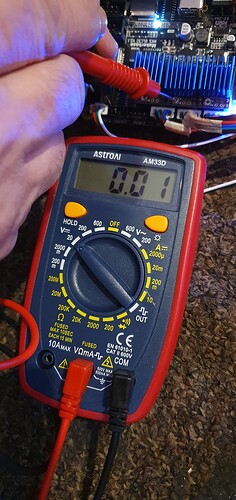

1 Step Stick indicate 1,24…the next 1,76…last nothing 0.00…i tried turning the potentiometer in both direction and nothing changed on the voltmeter

i used this voltmeter

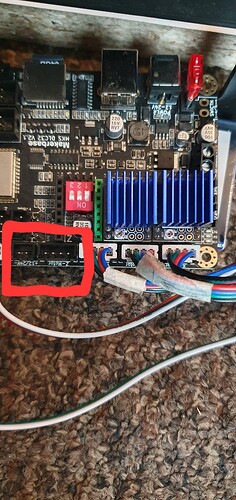

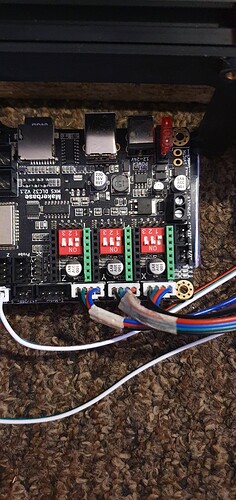

i used the GND next to the Zmotor slot…see te pic

i put black lead test on ”-” and red lead on Step sticks potentiometer

I’m not familiar with the TMC2225. You can use the formula in the spec sheet (And some algebra skills, which I don’t have) to calculate the correct VREF value.

The VREF of the second stepper - Y axis - is at 1.76V. This seems very high and could explain, why it fails after a few minutes of engraving. Try lowering it as @parsec suggested.

The Y axis has two motors. Are they connected to the X and Y ports on the board?

And the X axis is using the Z connector?

The 0.00V on the third step stick sounds bad. If this step stick is really the 2nd Y motor, the axis might still move but explains the noise you are hearing.

Always make sure, you plug out the power when you remove or insert the step sticks btw.

i can buy another driver?..ex A4988 Step sticks? or DRV8825?

X axis use X connector and Y axis is connected to Y1 and Y2

Sure. I am happy with the TMC2209 or TMC2208. They are silent like the one you have.

A4988 is like the standard driver and cheaper.

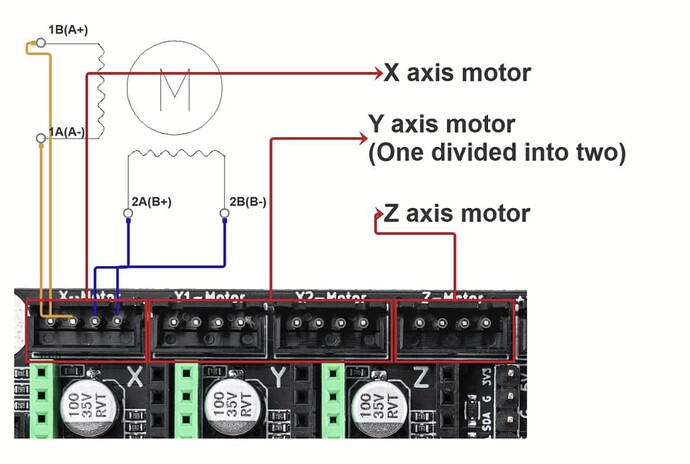

Ah, I see! So, the Y stepper drives both motors:

From: MKS-DLC32/MKS-DLC32-main/doc/DLC32 wiring manual.pdf at main · makerbase-mks/MKS-DLC32 · GitHub

That would mean, you only only need two stepper drivers… I’m confused.

1 Y direct 2 Y reverse.