Hello, this is an older post but did it ever get solved. ?

I also would like to lower the minimum power goin to my laser.

Hello, this is an older post but did it ever get solved. ?

I also would like to lower the minimum power goin to my laser.

Yes. For me the problem was the pwm frequency the grbl board uses to control the laser.

Had a pretty cheap driver inside the laser module I guess. Lowering the pwm frequency from 5000 to 1000 did work for me.

It depends on your controller board how you can do that.

I have a Monport control board that I installed so that my China brand machine is Lightburn compatable. So you changed your S value from 5000 to 1000 ?

No, s value is something different.

I don’t know that board sorry. Some boards have $flags you can simply change via console.

Others you have to re compile the whole grbl software.

My solution worked for diode laser module btw.

Did you follow the grbl setup instructions from Lightburn… This should all be covered.

How this operates with a K40 type depends on how the controller is wired to the lps (laser power supply). There are a couple of control options that control how the lps is fired.

![]()

Lightburn is working great with this co2 machine, I feel everything is set up correct, other than I would like to control and lower the output of laser. It seems very hot. The lowest I can get on the Ma meter is 2-3ma. at 4000mm/m this still burns deep into wood and Romark. I am not able to engrave on Anodised Black business cards as it removes all the black. I would like to be able to engrave images with the greyscale funtion. It is not working near as well as my 10 watt diode machine.

This is really a new thread, the original was for a diode laser along with it being over a year old.

@JohnJohn may be able to move it for us…

Which machine do you have, your profile isn’t very forthcoming.

I’d switch units to mm/s as most lasers operate well in the 50 to 400mm/s speed range… slower for cutting.

4000mm/m is about 66mm/s, pretty slow for most co2 machines. This is especially true with the more delicate work you appear to be doing. Even with a K40 type compared to your diode of 10W, the K40 is 3 to maybe 5 times more powerful… So running in the 3 to 5 times speed range seems appropriate.

This is actually lower than I’d suggest. Co2 draws a bit of current at startup… I’d try to stay a bit above that, such as 5mA. Determine the lowest current it will lase consistently…

I don’t think this is a problem.

Likely too much power and a slow speed…

For all practical applications, you can’t… the grayscale with a co2 is depth, not what most would think of a grayscale, per se.

![]()

Done… and thank you ![]()

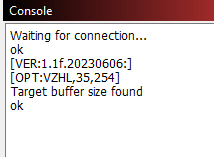

Exactly! The start message when the Monport Controller first connects to LightBurn is a great bit of information to help us understand exactly which controller and firmware revision number we’re dealing with.

Also true! For CO2 Lasers this is the general preference. It can be adjusted under Edit, then Settings then look for Units / Grids about halfway down on the left. Carefully click OK at the bottom to make sure the change to the settings ‘sticks’.

Thanks for the reply, I will look into these changes. And basically travel faster? I may have to increase the max limits.

It turns out that Monport makes more than one controller, so a picture of the one you’ve got would help us identify it.

The start message when the engraver connects will also help.

After you see that start message and the word ok, in the Console window, if it’s a GCode controller, it should respond to a request for Machine Settings. To get a dump of the Machine Settings on most GCode controllers type the following into the Console Window:

$$

Then press Enter.

You can scroll back to the start message, or the beginning of a report, Select and Copy any text from the Console window and Paste it into a reply here for further comment and analysis. ![]()

Here is a Screen shot of the stat up…

Heres my GRBL settings…$$

$0=10

$1=25

$2=3

$3=4

$4=0

$5=0

$6=0

$10=1

$11=0.010

$12=0.002

$13=0

$20=1

$21=1

$22=1

$23=3

$24=25.000

$25=3500.000

$26=250

$27=3.000

$30=255

$31=0

$32=1

$33=1

$34=1

$35=0

$36=0

$37=1

$39=1

$100=160.000

$101=160.000

$102=160.000

$110=6000.000

$111=6000.000

$112=100.000

$120=500.000

$121=500.000

$122=20.000

$130=390.000

$131=420.000

$132=200.000

ok

I hope to be able to get the power lower to be able to do greyscale images on various materials,

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.